Surface reflection type metallic screen and method of manufacturing the same

A surface reflection and screen technology, applied in optics, instruments, projection devices, etc., can solve problems such as unsuitable use, difficult to remove dust on the screen surface, etc., and achieve the effect of high resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

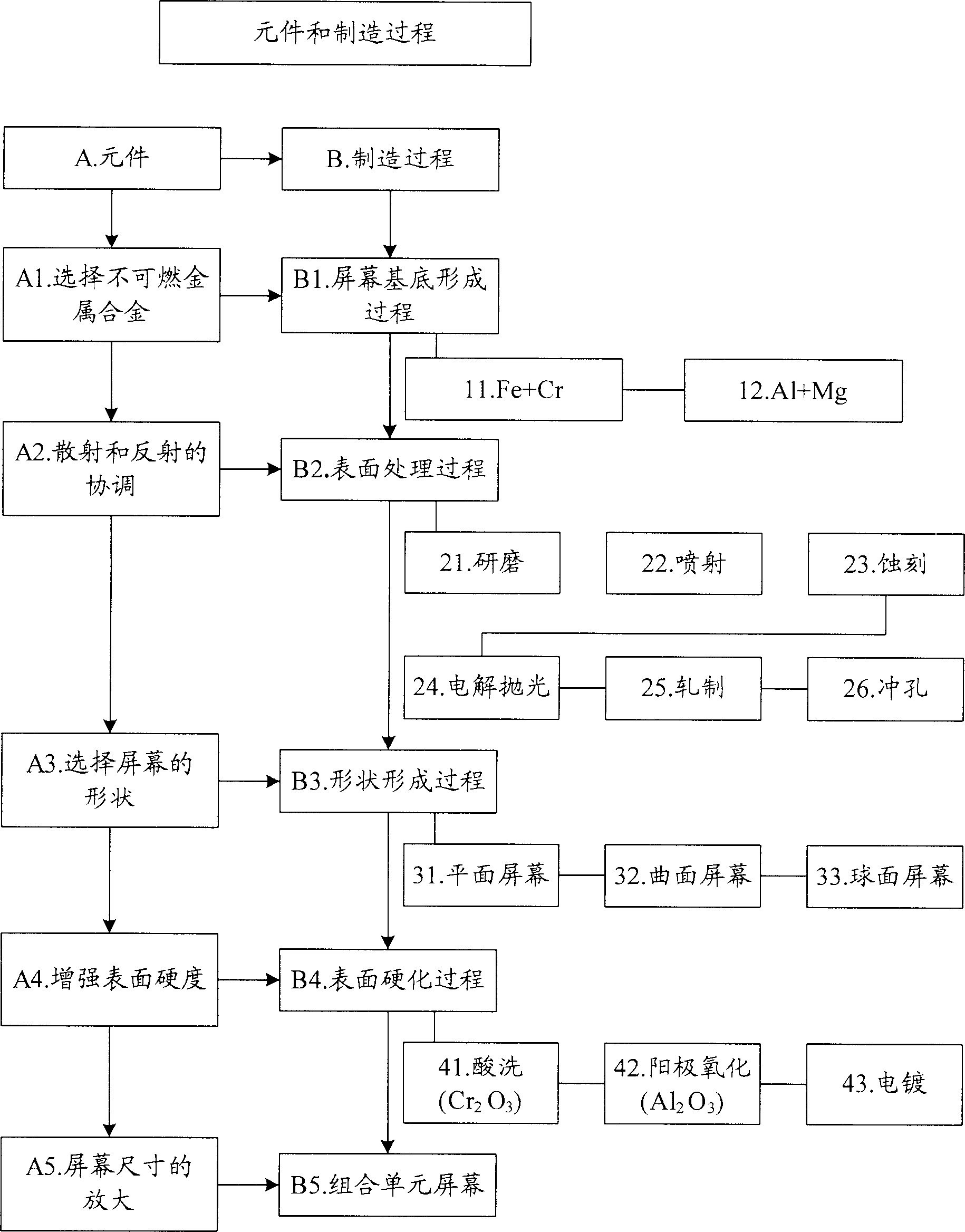

[0058] figure 1 It is a block diagram illustrating the elements and manufacturing process of the screen according to the present invention.

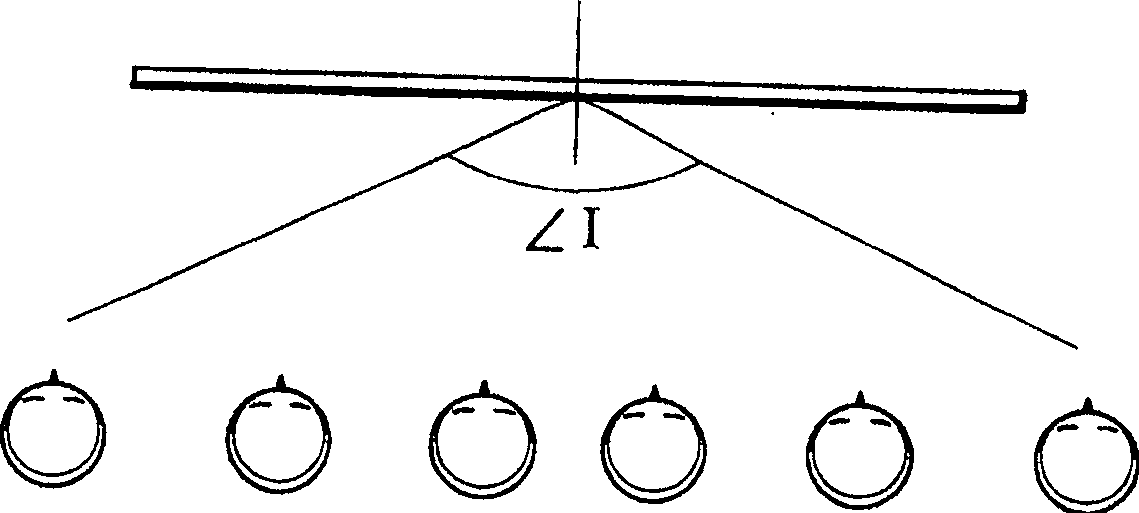

[0059] Such as figure 1 As shown in, the present invention includes: selecting a non-flammable metal alloy (A1), coordination of scattering and reflection (A2), selecting the shape of the screen according to its application (A3), strengthening the hardness of the screen surface (A4) and executing the screen To zoom in (A5).

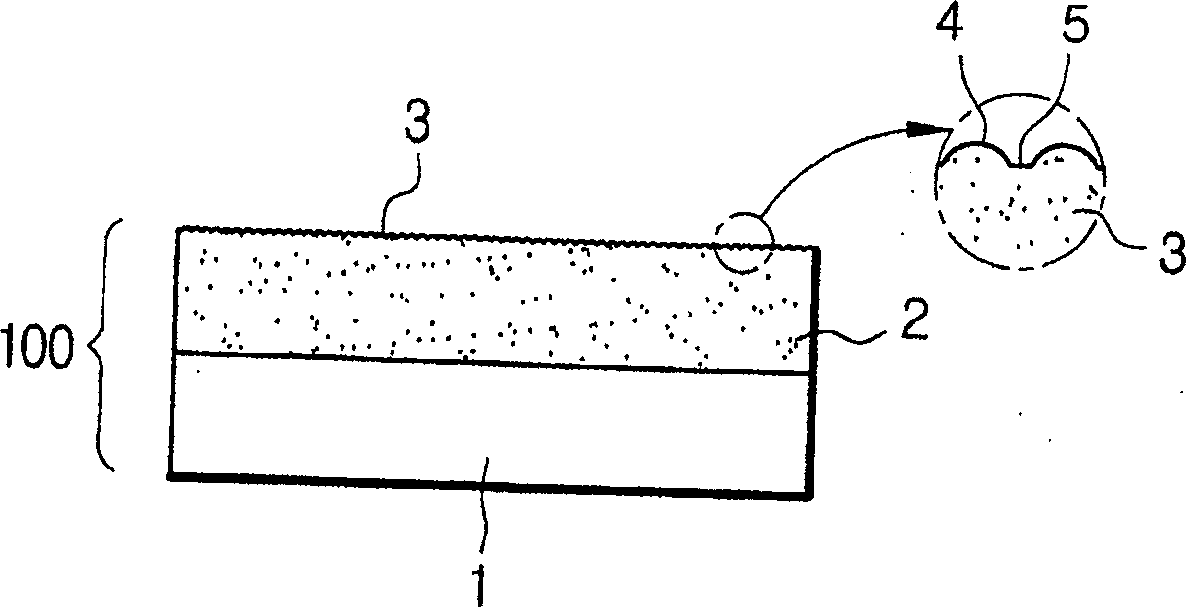

[0060] According to an embodiment of the present invention, a surface reflective screen formed of a non-combustible metal has a silver-white non-combustible metal sheet, wherein the metal sheet is made of an alloy of iron (Fe) and chromium (Cr), or iron (Fe) and It is formed by an alloy of chromium (Cr) and a small amount of nickel (Ni).

[0061] Through buffing, spraying,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com