Technology for producing pollution-free liquid cigarette

A production process and technology for cigarettes, which are applied to tobacco, tobacco processing, and cigar manufacturing, etc., can solve the problems of large amount of three wastes, high cost, low liquid recovery rate, etc., and achieve low production cost, eliminate hazards, and eliminate fire hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention relates to a production process of liquid cigarettes. The process includes the selection and treatment of raw materials, dry distillation, cooling, condensation and homogenization, fine filtration, seasoning and packaging procedures. The treatment of raw materials is to use tobacco leaves with a total sugar content of less than 4% and nicotine less than 2% as raw materials, manually screen to remove soil and sundries, spray wet, flatten leaf bones, shred, put 40-50 Soak for 3-4 hours in a soaking tank at ℃, take out the shredded tobacco and squeeze out 85-90% of the water content, and process it into shredded tobacco cake.

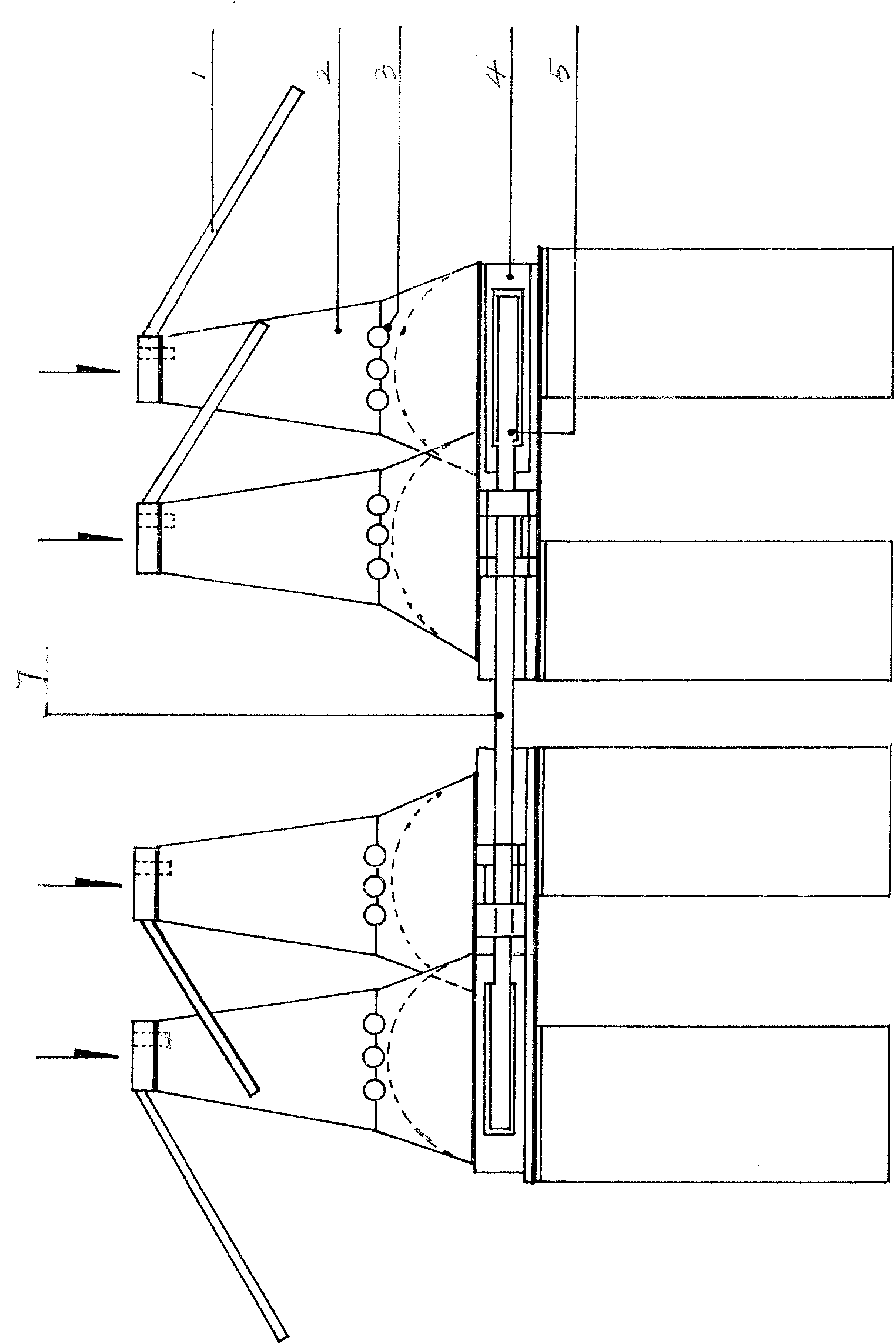

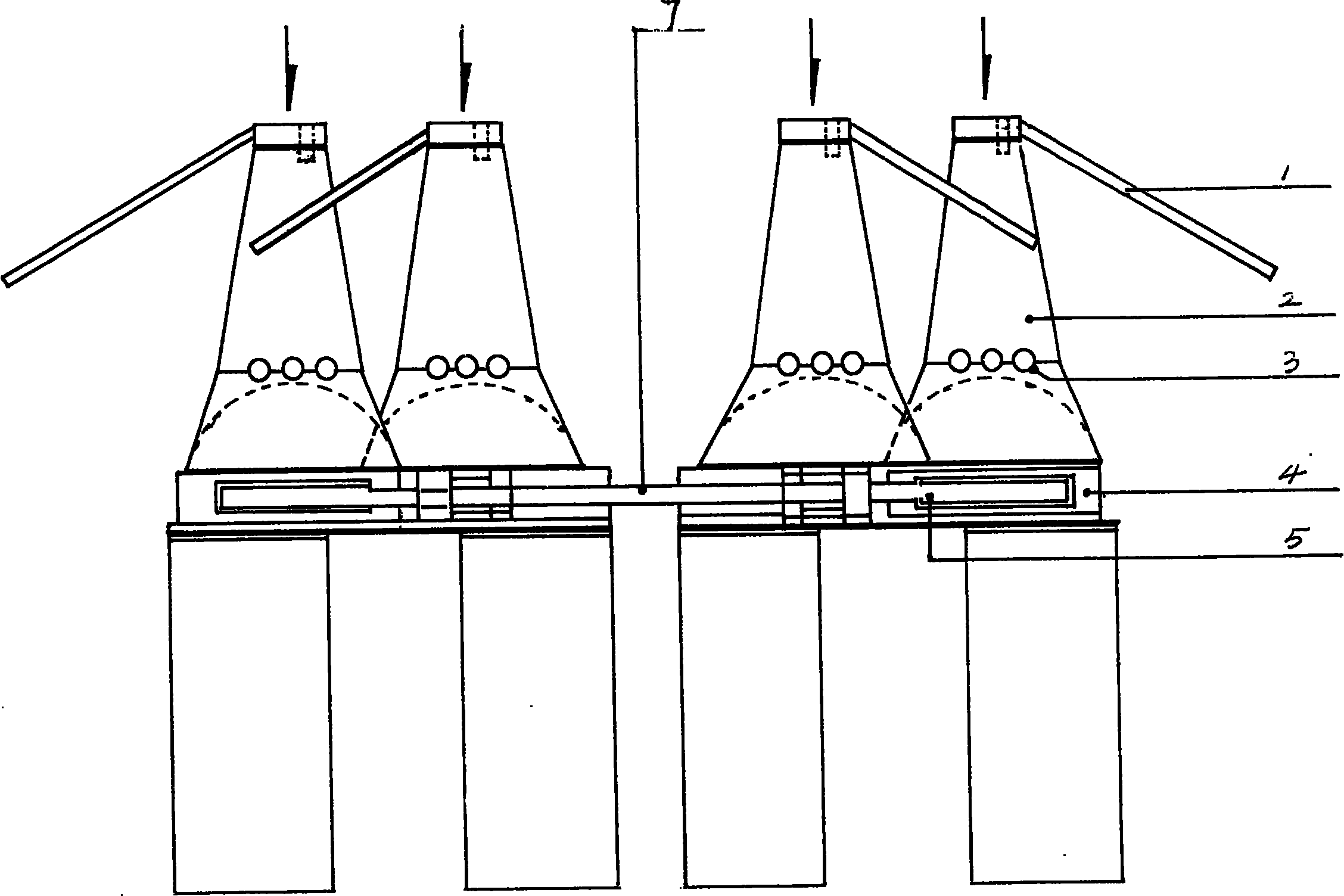

[0011] Dry distillation is carried out in four still-tower-type dry distillation kettles in sections. The dry distillation process is: send the shredded tobacco cake into the dehydration kettle, and after 40 minutes of dry distillation at a temperature of 105°C, the water turns into steam, and then sends the shredded tobacco cake into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com