Method for synthesizing biodiesel utilizing swill water oil

A technology for synthesizing biology and biodiesel, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problems of unrecyclable catalysts, low acid catalytic efficiency, dark product color, etc., and achieve good industrialization prospects and process The effect of simplicity and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

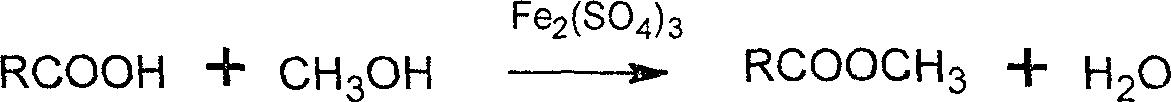

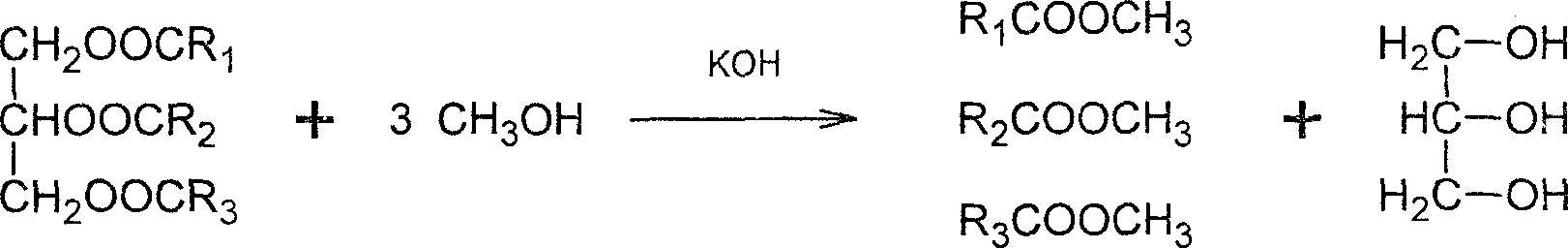

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The hogwash oil recovered by the catering industry is used to separate and remove food residues such as protein. Add 4Kg hogwash oil, 1.4Kg methanol and 0.08Kg catalyst ferric sulfate into the reaction vessel, stir and heat to about 95°C. After reacting for 4 hours, the catalyst ferric sulfate was removed by centrifugation, and the ferric sulfate can be recovered and reused. Add 0.04Kg potassium hydroxide to the obtained oil product, stir and keep the temperature at about 65°C. After reacting for 1 hour, the product is left to stand or centrifuged to separate into two layers of oil and water. The oil layer is mainly fatty acid methyl ester and a small amount of soap , the water layer is excess methanol, soap, glycerin and potassium hydroxide; and then washed with 0.4L of 80 ° C hot water and centrifuged to remove the soap in the oil layer, the crude biodiesel product can be obtained. The crude product is distilled under vacuum to obtain a refined biodiesel product.

Embodiment 2

[0027] The hogwash oil recovered by the catering industry is used to separate and remove food residues such as protein. Add 4Kg of hogwash oil, 1.0Kg of methanol and 0.1Kg of catalyst ferric sulfate into the reaction vessel, stir and heat to about 80°C. After reacting for 6 hours, the catalyst iron sulfate was removed by centrifugation. Add 0.06Kg potassium hydroxide to the obtained oil product, stir and keep the temperature at about 80°C. After reacting for 0.5 hours, the product is left to stand or centrifuged to separate into two layers of oil and water. The oil layer is mainly fatty acid methyl ester and a small amount of soap , the water layer is excess methanol, soap, glycerin and potassium hydroxide; after washing with 0.4L of 85°C hot water and centrifuging to remove the soap in the oil layer, the crude biodiesel product can be obtained. The crude product is distilled under vacuum to obtain a refined biodiesel product.

Embodiment 3

[0029] The hogwash oil recovered by the catering industry is used to separate and remove food residues such as protein. Add 4Kg hogwash oil, 0.7Kg methanol and 0.13Kg catalyst ferric sulfate into the reaction vessel, stir and heat to about 70°C. After reacting for 3 hours, the catalyst iron sulfate was removed by centrifugation. Add 0.08Kg potassium hydroxide to the obtained oil product, stir and keep the temperature at about 95°C, after 2 hours of reaction, the product is left to stand or centrifuged to separate into two layers of oil and water, the oil layer is mainly fatty acid methyl ester and a small amount of soap , the water layer is excess methanol, soap, glycerin and potassium hydroxide; after washing with 0.4L of 90°C hot water and centrifuging to remove the soap in the oil layer, the crude biodiesel product can be obtained. The crude product is distilled under vacuum to obtain a refined biodiesel product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com