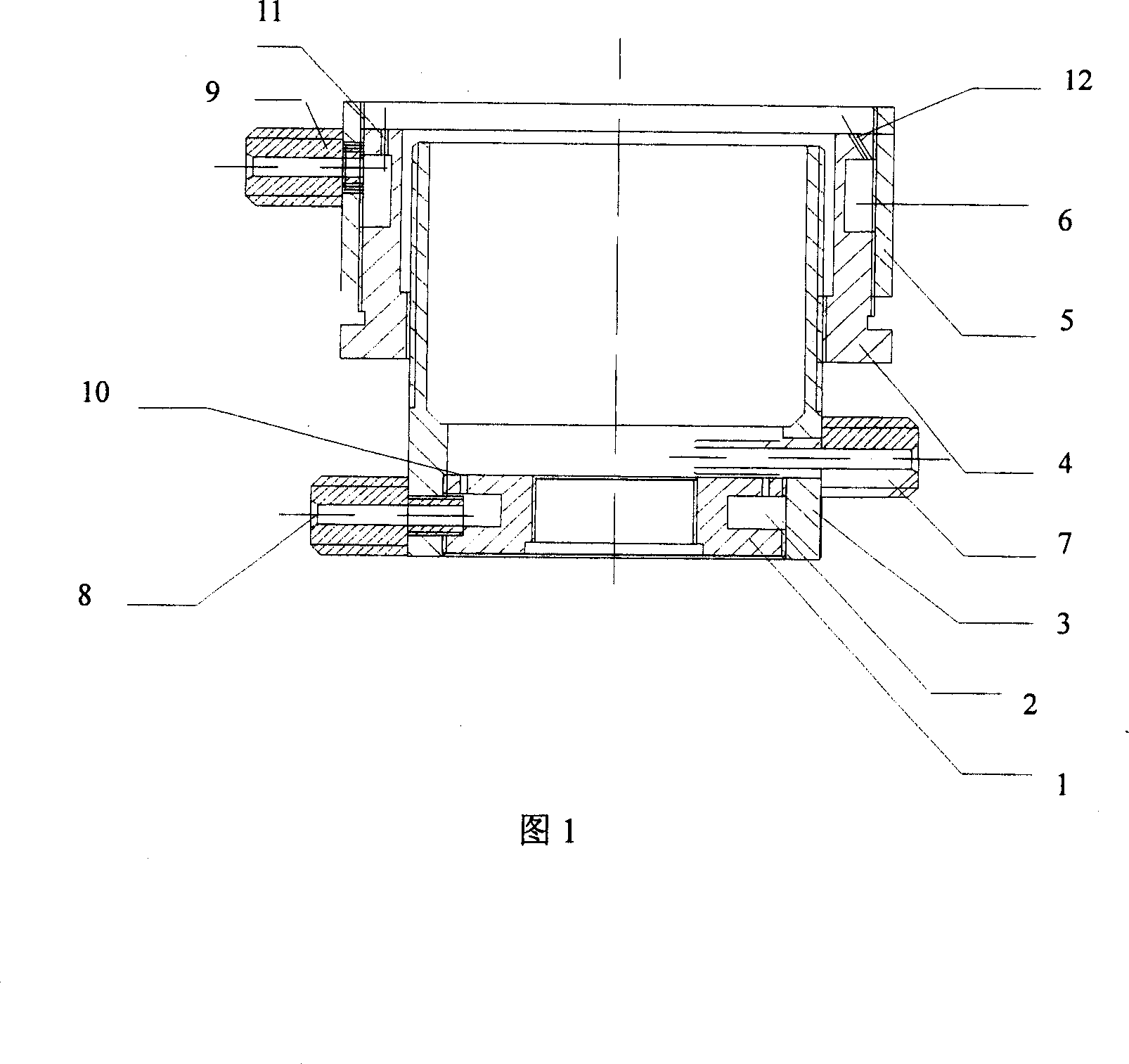

Porous titanium coating atmospheric plasma spraying gas protecting apparatus and its spraying method

A gas protection device and plasma technology, which is applied in the field of biomedical materials engineering, can solve the problems of insufficient consideration of the flow direction of the protective gas, metal oxidation, and low metal spraying efficiency, so as to improve the spraying efficiency and prevent rapid escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Connect and fix the base 1 of the inert gas protection device with the nozzle on the conventional atmospheric plasma spraying equipment, soak 50% of the titanium powder with a particle size of 40 microns and 50% of the titanium powder with a particle size of 200 microns in alcohol, and then use Ultrasonic mixing for 30 minutes, after drying at room temperature, use argon gas to feed the titanium powder into the powder transfer interface tube 7 on the gas protection device, and use the inert gas protection cover formed by this device. Under the action of the inert gas protection cover, use the following optimization Spraying titanium powder on the titanium substrate to obtain the biomedical porous titanium coating. The specific spraying process parameters used in this embodiment are shown in Table 1 of Spraying Parameters. The XRD analysis of the coating obtained under the spraying process parameters, the results are shown in Figure 4 , The results show that the coating is ...

Embodiment 2

[0040] Connect and fix the base 1 of the inert gas protection device with the nozzle on the atmospheric plasma spraying equipment, soak 80% of the 20-micron and 20% of the 250-micron titanium powder in alcohol, and then mix with ultrasonic for 30 minutes in the atmosphere. After drying, use argon gas to feed the titanium powder into the powder conveying interface tube 7 on the gas protection device, and use the inert gas protection cover formed by this device. Under the action of the inert gas protection cover, use the following optimized spraying process parameters to spray the titanium powder Spray on the titanium substrate to obtain the biomedical porous titanium coating. The specific spraying process parameters used in this embodiment are shown in Table 2 of Spraying Parameters. The XRD analysis results show that the coating is composed of titanium, the coating is not oxidized, and no titanium oxide is generated. The scanning electron microscope analysis of the coating confirm...

Embodiment 3

[0042] Embodiment 3: Connect and fix the base 1 of the inert gas protection device with the nozzle on the atmospheric plasma spraying equipment, soak 20% of 40 micron and 80% of 100 micron titanium powder in alcohol, and then mix with ultrasonic 30 Minutes, after doing what in the atmosphere, use argon to send the titanium powder into the powder delivery interface tube 7 on the gas protection device, use the inert gas protection cover formed by this device, and use the following optimized spraying under the action of the inert gas protection cover Process parameters: The titanium powder is sprayed on the titanium substrate to obtain the biomedical porous titanium coating. The specific spraying process parameters used in this embodiment are shown in Table 3 of Spraying Parameters. The XRD analysis results of the coating obtained under the spraying process parameters show that the coating is composed of titanium, the coating has not been oxidized, and no titanium oxide is formed. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com