Method for developing processing

A processing method and developer technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of developer reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

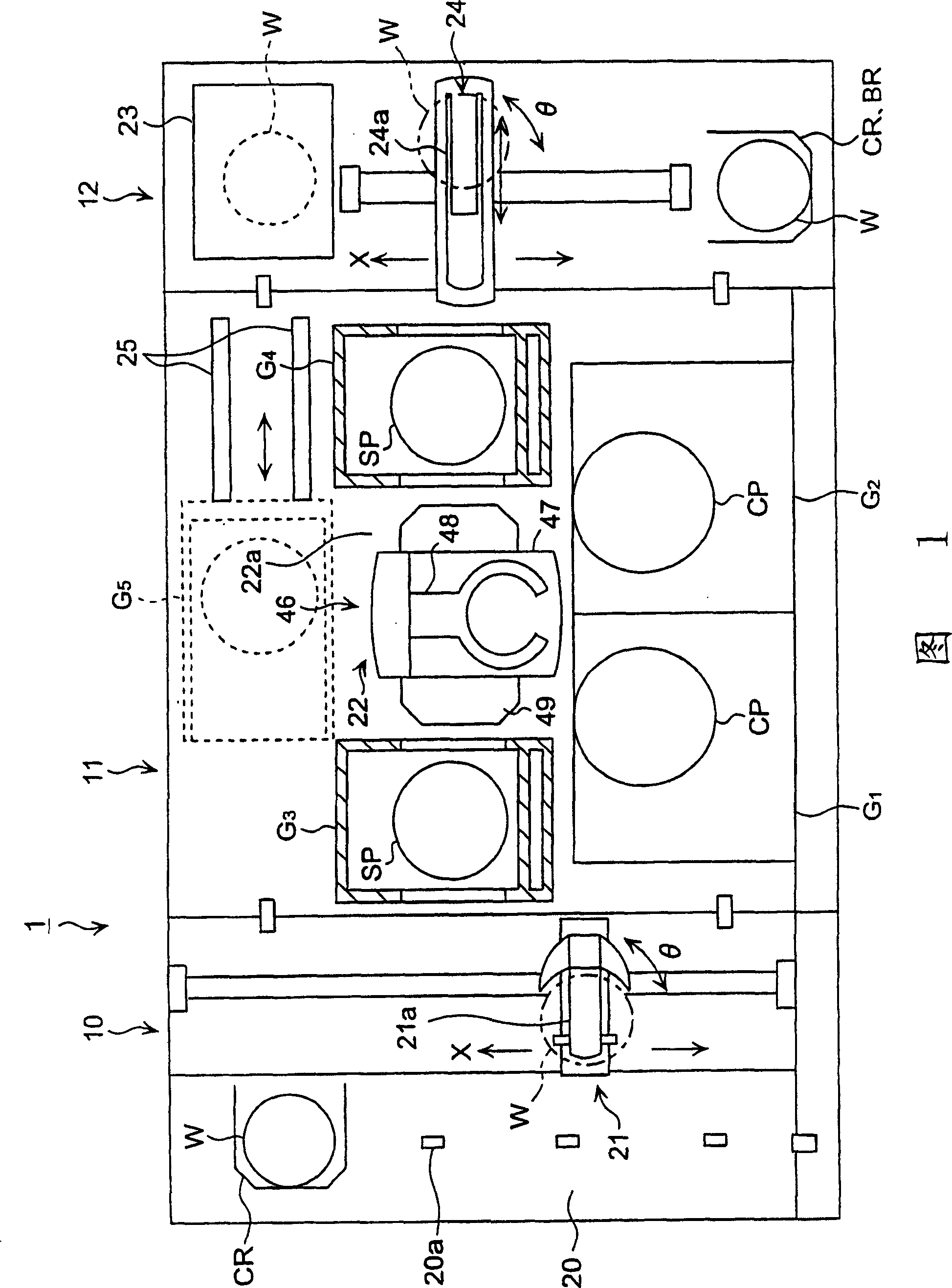

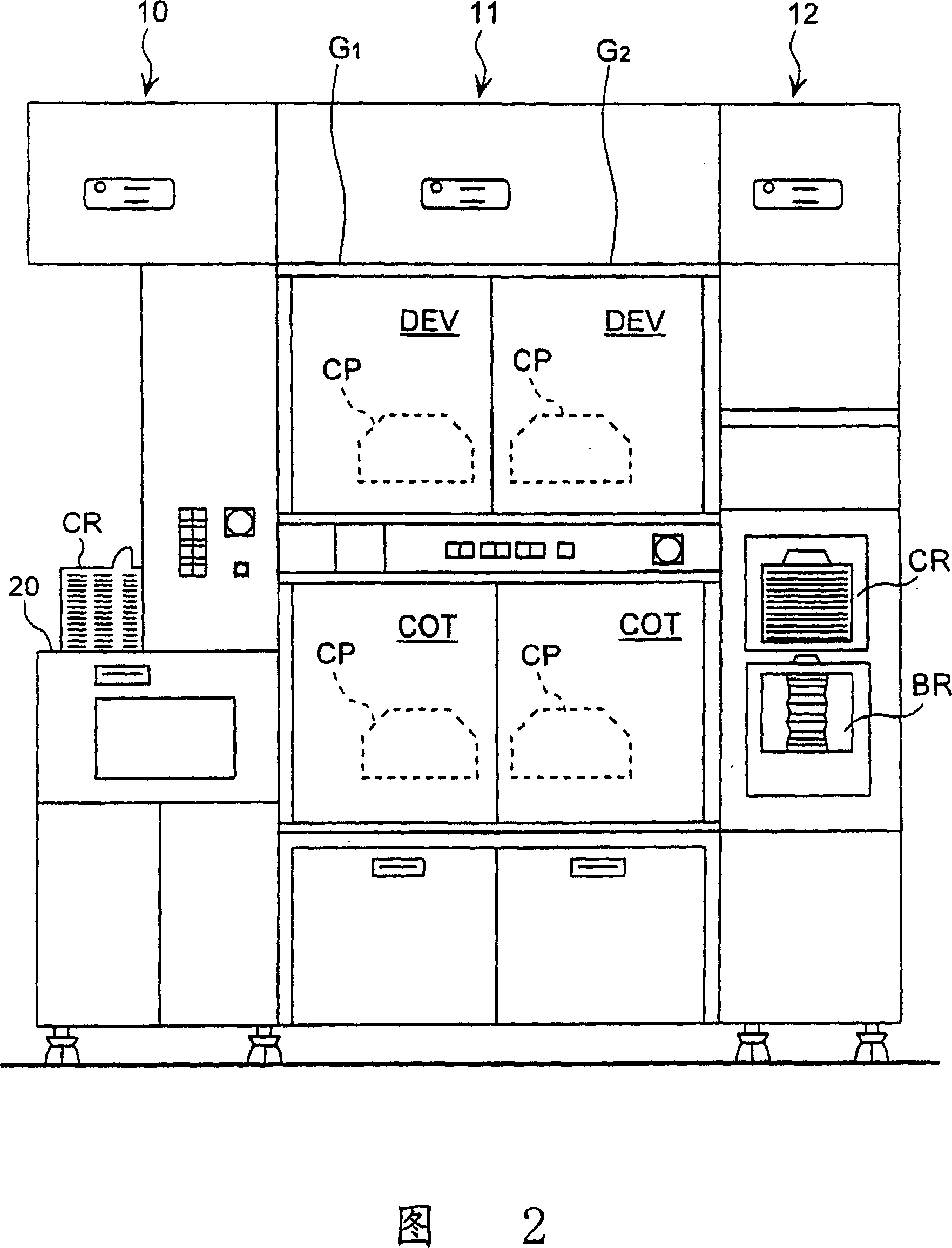

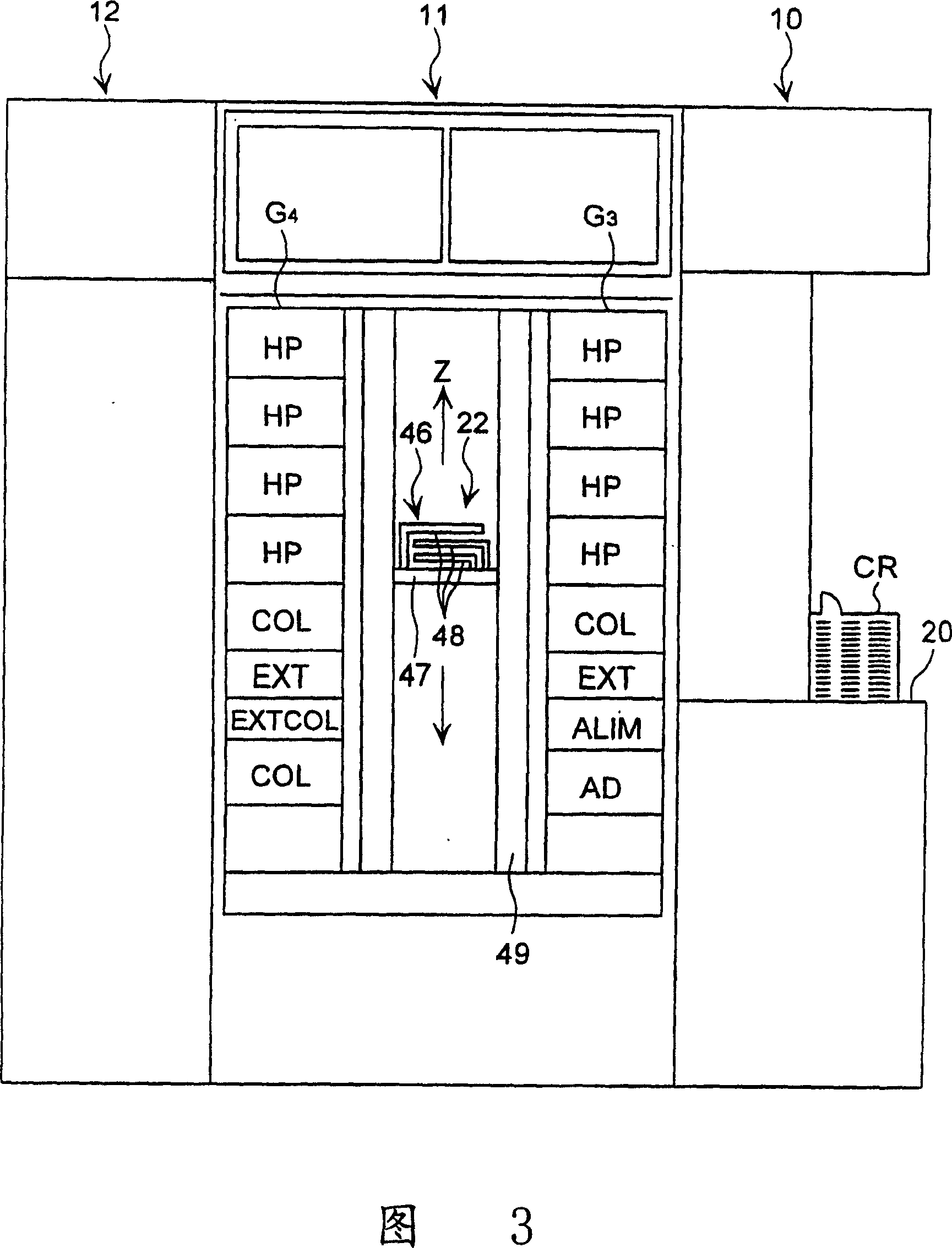

[0042] Embodiments of the present invention will be described in detail below with reference to the drawings. Here, a development treatment method using a resist coating development treatment system that continuously performs from application of a resist to a semiconductor wafer (wafer) to development treatment will be described.

[0043] figure 1 is a schematic plan view showing a resist coating and development processing system, figure 2 is its front view, image 3 is its rear view. This resist coating and development processing system 1 has a box-type table 10 as a transfer table, a processing table 11 having a plurality of processing units, and a wafer W provided between and an exposure device not shown adjacent to the processing table 11. The interface part 12.

[0044] The box stage 10 carries out operation from another system to the present resist coating and developing processing system 1 in a state where a plurality of, for example, 25 wafers W as objects to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com