Manufacturing method of interdigital transducer of surface acoustic wave filter

An interdigital transducer and surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as cracking, unevenness, and CD unevenness of heated wafers, avoiding uneven heating and good thermal conductivity. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

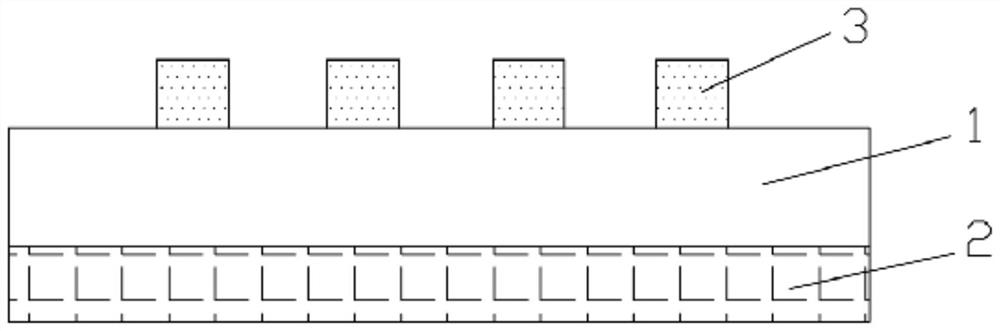

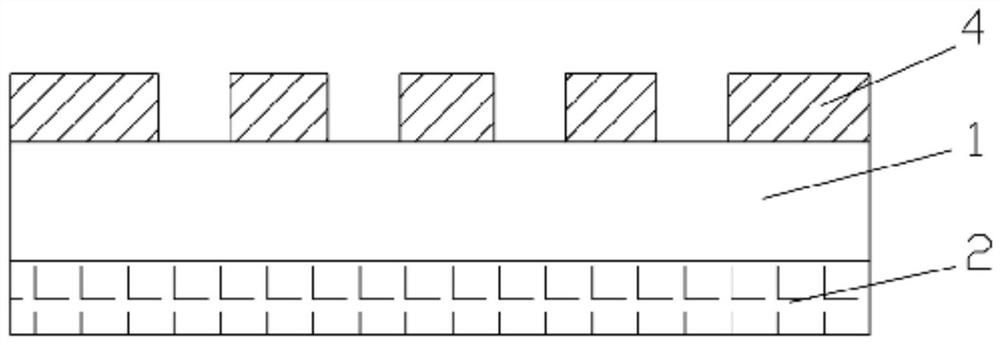

[0048] There is a significant difference in the effects of plating titanium on the back of the wafer in Example 1 and plating nickel on the back of the wafer in Comparative Example 1. In the IDT yellow light process, the wafer needs to be developed on a hot plate, and the photoresist is baked and cured after development. The wafer deformation after the hot plate is developed can be referred to figure 2 a and 2b. Such as figure 2 As shown in a, the wafer coated with titanium metal on the back has almost no deformation, the photoresist is heated more uniformly, the CD control on the edge of the wafer is better, and the overall uniformity is also better. Such as figure 2 As shown in b, the nickel-plated wafer on the back is obviously deformed, and obvious warping is found on the edge of the wafer.

[0049] Further do the hot plate test experiment, the experimental results are as follows image 3 As shown, in Example 1, the phenomenon of flat edge warping was not found in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com