Automatic weld seam position based on circular laser vision sense

A visual sensing and automatic positioning technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of difficult to determine depth information and low efficiency, achieve high efficiency and precision, enhance operability, and avoid structure complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

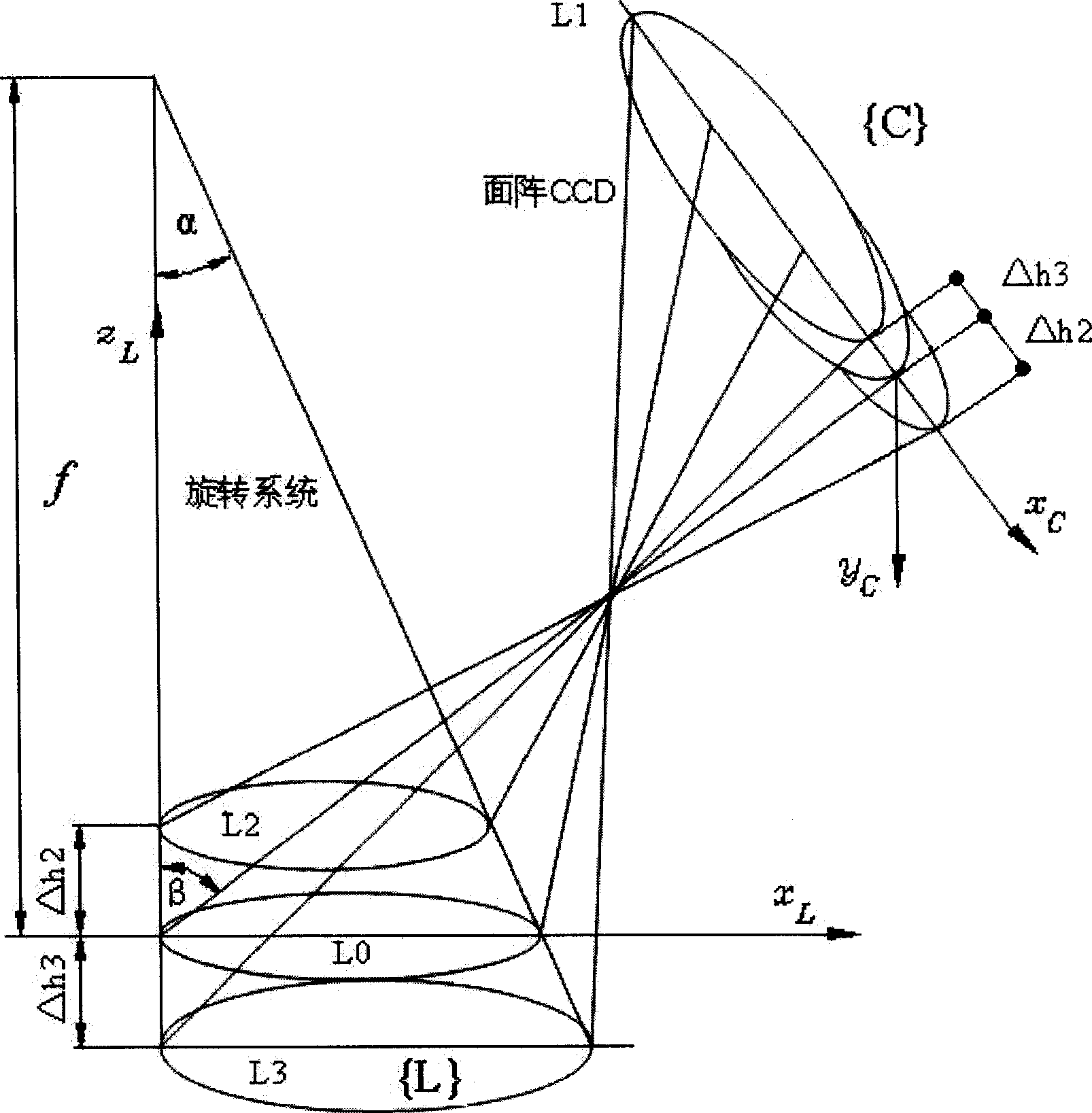

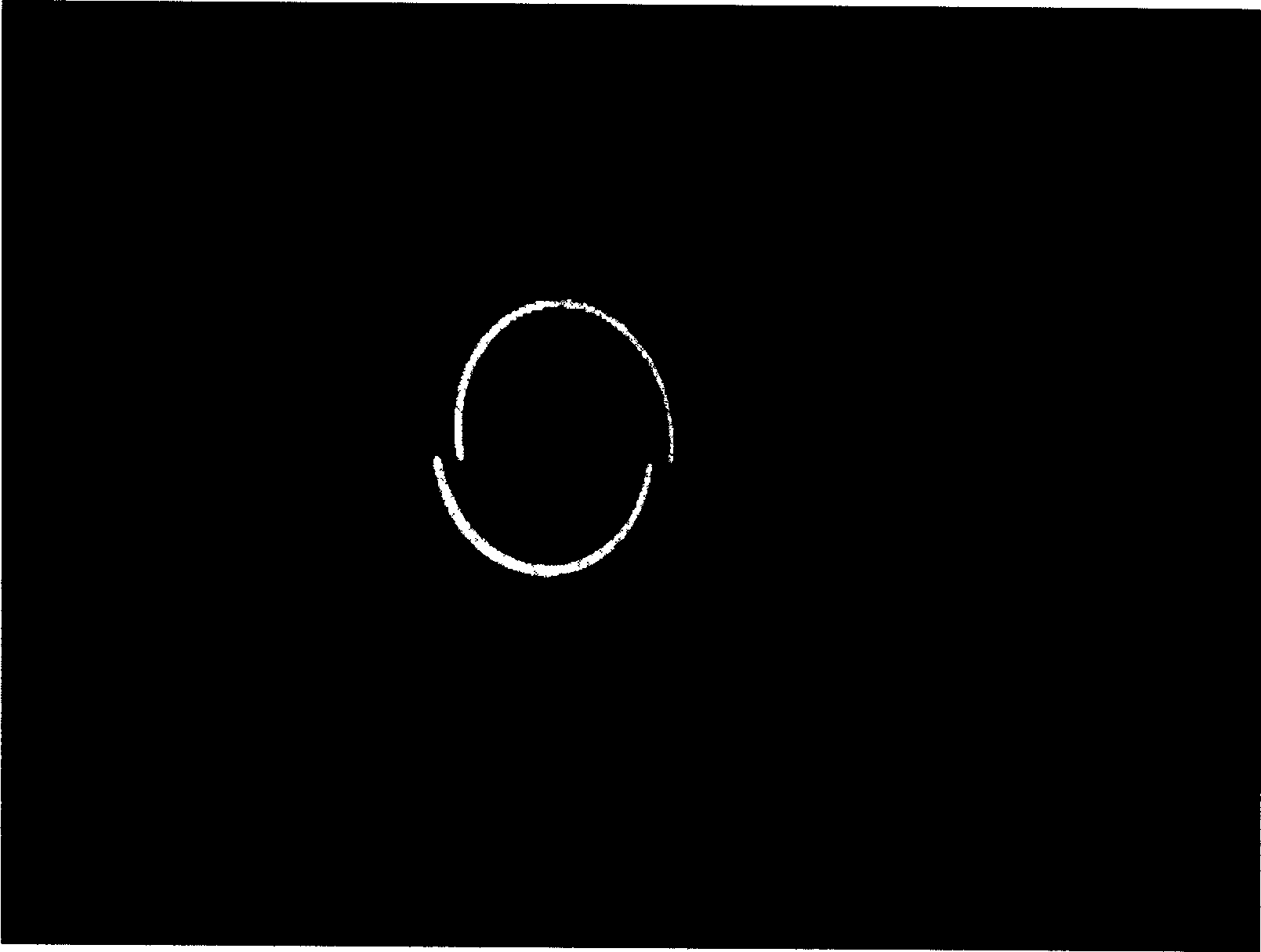

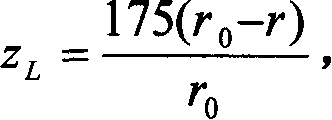

[0017] like figure 1 As shown, the point-shaped laser emitted by the laser diode is projected onto the surface of the welded workpiece to be detected through the scanning action of the rotating lens of the laser vision sensor. The area array CCD camera detects the weld seam and the ring laser track through the image acquisition card, realizes A / D conversion and collects it to the computer, and the computer uses the differential algorithm to identify the detected laser scanning track after image processing such as image filtering and image segmentation. Feature points. These feature points are where the welds are located. Finally, according to the proposed "circle radius and depth relationship" algorithm, the three-dimensional coordinates of the weld feature points in the laser cone coordinate system are obtained. And through the conversion relationship between the laser cone coordinate system and the robot world coordinate system, the three-dimensional coordinates of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com