Micro-camera lens system

A miniature camera and lens technology, applied in the field of camera lens systems, can solve the problems of high cost and low imaging quality, and achieve the effects of easy processing, cost reduction, and large feature size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

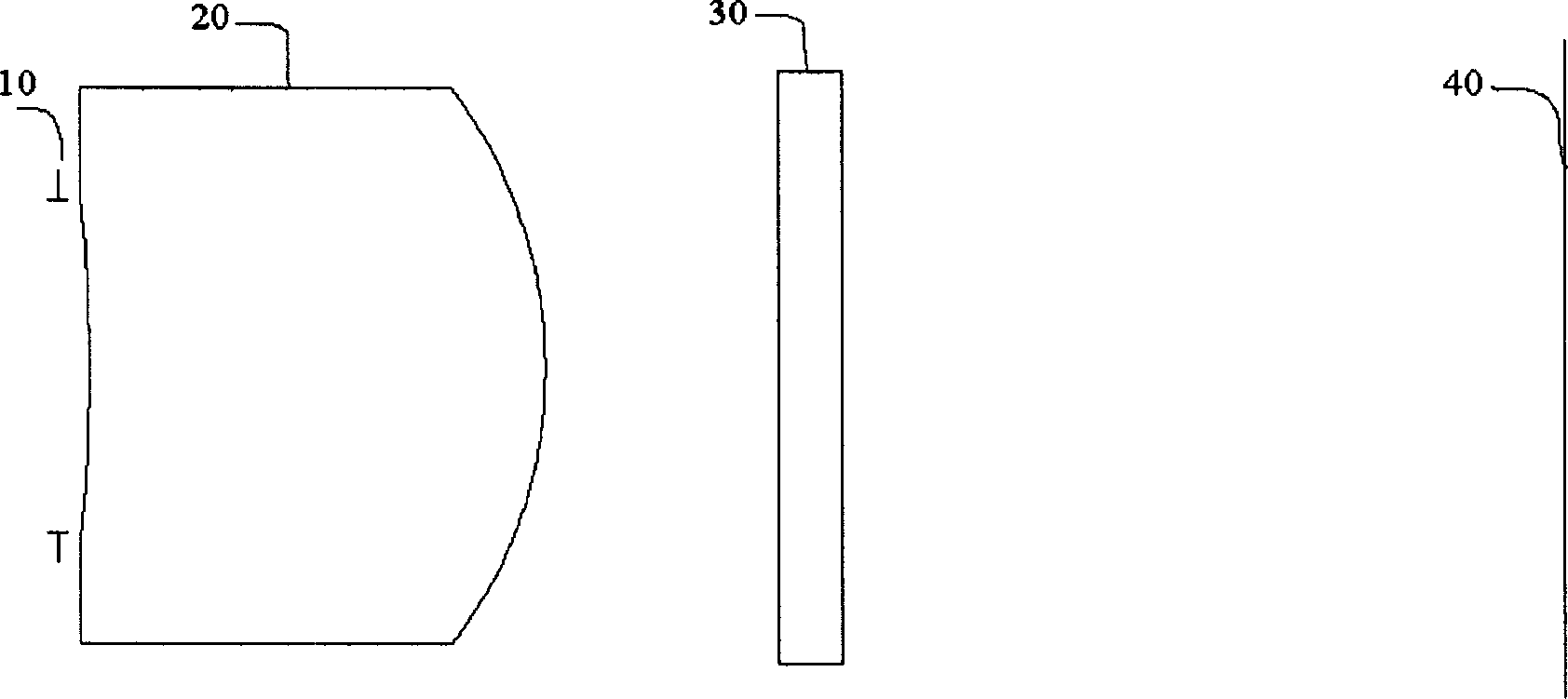

Method used

Image

Examples

no. 1 example

[0058] The miniature camera lens system meets the conditions of Table 1, Table 2 and Table 3:

[0059] f=6.00mm T=9.64mm FNo=2.8 2ω=40°

[0060]

[0061] Diffraction phase coefficient

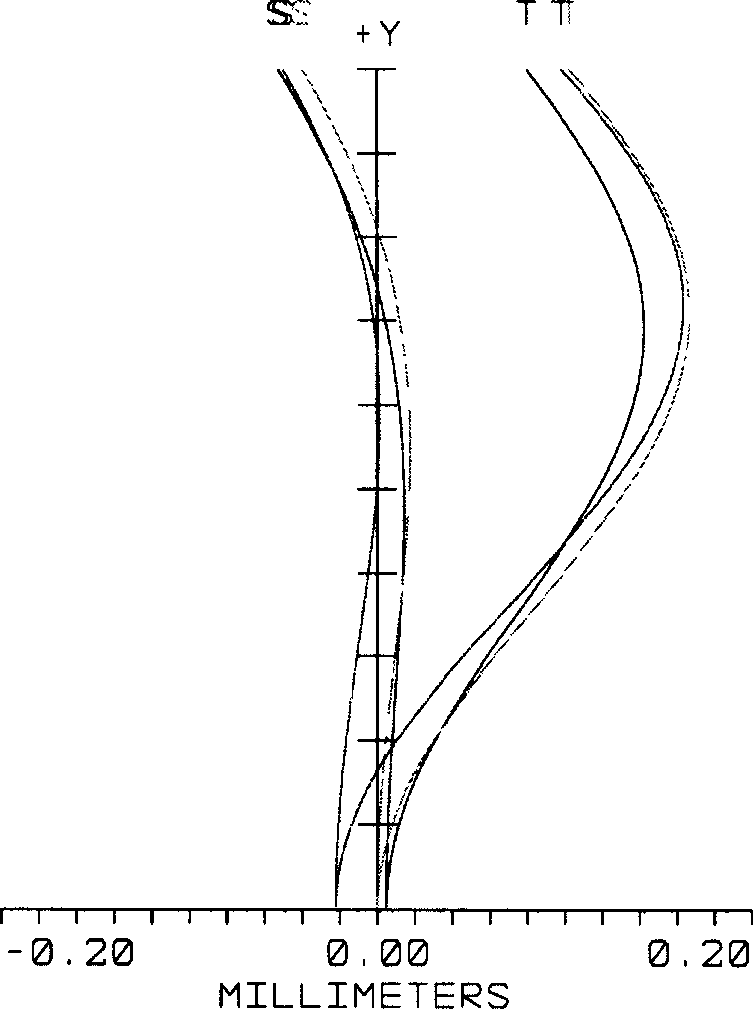

[0062] In the miniature camera lens system of the first embodiment, its curvature of field and distortion, on-axis spherical aberration and chromatic aberration are respectively as follows Figure 3A to Figure 4 shown. in Figure 3A and Figure 3B represent the field curvature curve and the distortion curve, respectively. It can be seen from the figure that the above-mentioned curvature of field, distortion, and on-axis spherical aberration and chromatic aberration can be well corrected.

no. 2 example

[0064] The miniature camera lens system meets the conditions of Table 4, Table 5 and Table 6:

[0065] f=6.00mm T=9.60mm FNo=ω=40°

[0066]

[0067] Diffraction phase coefficient

[0068] In the micro camera lens system of the second embodiment, its curvature of field and distortion, on-axis point spherical aberration and chromatic aberration are respectively as follows Figure 5A to Figure 6 shown. in Figure 5A and Figure 5B represent the field curvature curve and the distortion curve, respectively. It can be seen from the figure that the above-mentioned curvature of field, distortion, and on-axis spherical aberration and chromatic aberration can be well corrected.

no. 3 example

[0070] The miniature camera lens system meets the conditions of Table 7, Table 8 and Table 9:

[0071] f=5.00mm T=8.07mm FNo=2.8 ω=50°

[0072]

[0073] Diffraction phase coefficient

[0074] In the miniature camera lens system of the third embodiment, its curvature of field and distortion, on-axis point spherical aberration and chromatic aberration are respectively as follows Figure 7A to Figure 8 shown. in Figure 7A and Figure 7B represent the field curvature curve and the distortion curve, respectively. It can be seen from the figure that the above-mentioned curvature of field, distortion, and on-axis spherical aberration and chromatic aberration can be well corrected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com