Organic electroluminescent device and preparation method thereof

An electroluminescent device, organic technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., to achieve the effect of small dispersion, reduced preparation process and cost, and increased proportion of forward light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

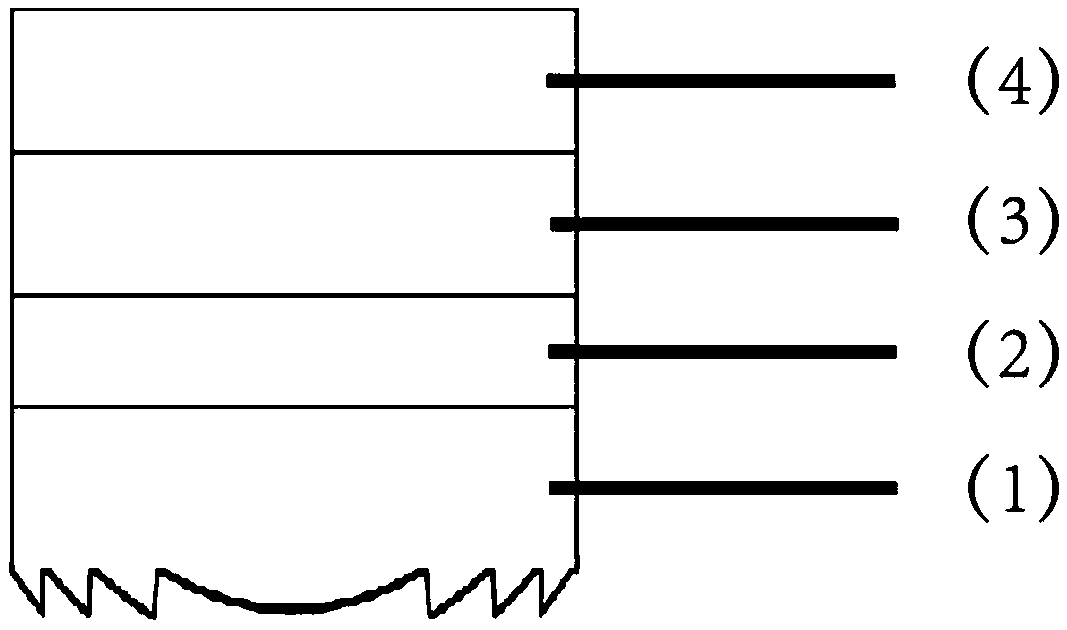

[0042] A method for preparing an organic electroluminescent device, comprising the following steps:

[0043] S1. On the surface of the roller or the flat plate, the female mold structure is processed by cutting tool engraving or laser ablation;

[0044] S2, using the roller or flat plate processed in step S1 to press out the Fresnel lens structure teeth on the base;

[0045] S3, post-processing and shaping the Fresnel lens substrate prepared in step S2;

[0046] S4, using ethanol, acetone ultrasonic and deionized water ultrasonic methods to clean the substrate, and dry after cleaning;

[0047] S5. There is no Fresnel lens structure layer on the substrate, and a transparent conductive film is prepared as a transparent anode, and the square resistance of the transparent anode is 5 to 30 ohms per square;

[0048] S6. Transfer the substrate prepared in step S5 into the vacuum chamber, control the rate of 1-10nm / s, and sequentially prepare organic functional layers by vacuum ther...

Embodiment

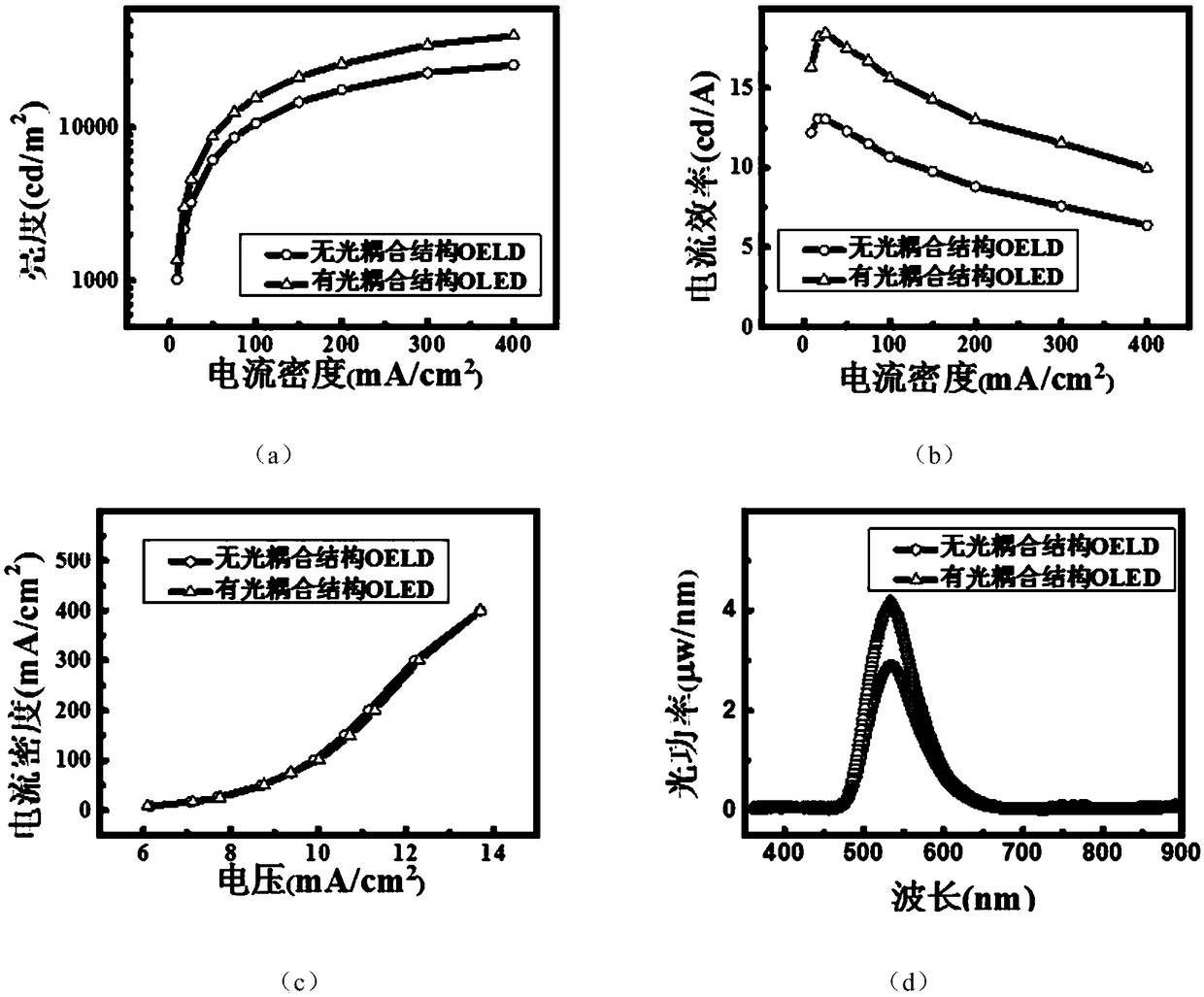

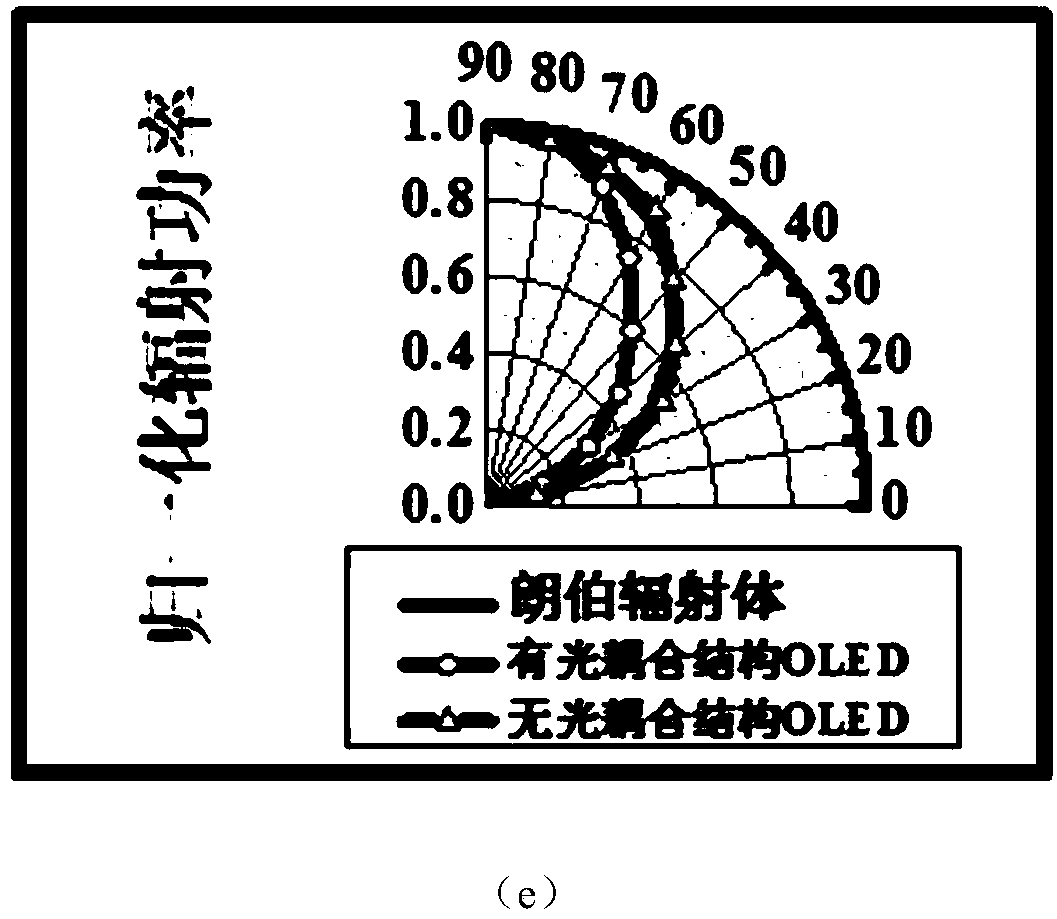

[0052] A green organic electroluminescent device, using a knife to carve a Fresnel lens negative mold on the surface of a glass plate, and preparing a Fresnel lens with a focal length of 16 mm and a groove pitch of 0.1 mm on a PET substrate by hot pressing . Indium tin oxide transparent conductive film was prepared on PET substrate by electron beam evaporation method.

[0053] Prepare organic functional layers sequentially by vacuum thermal evaporation method: 40nm thick 4,4′,4′-Tris[2-naphthyl (phenyl)amino]triphenylamine is the hole injection layer, 20nm thick N,N' -Diphenyl-N,N'-bis(2-naphthyl)-1,1'-biphenyl-4,4'-diamine as hole transport layer, 20 nm thick 8-hydroxyquinoline aluminum doped 10-(2-Benzothiazolyl)-2-,3,6-,7-tetrahydro-1,7-,7-tetramethyl-1H,5H,11H-(1)benzopyranpyran (6,7-8-I, J) Quinolinazine-11-1 was used as the light-emitting layer (the doping volume ratio was 1:0.03), and 40nm-thick 8-hydroxyquinoline aluminum was used as the electron-transporting layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com