Preparation method of metal nanoflakes

A technology of metal nano and nano sheets, which is applied in metal processing equipment, nanotechnology, transportation and packaging, etc., can solve the problems of difficult template method and non-template method preparation, metal nickel nano sheet preparation report has not been found, etc., to achieve convenient Reaction rate, wide-thickness ratio, and easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

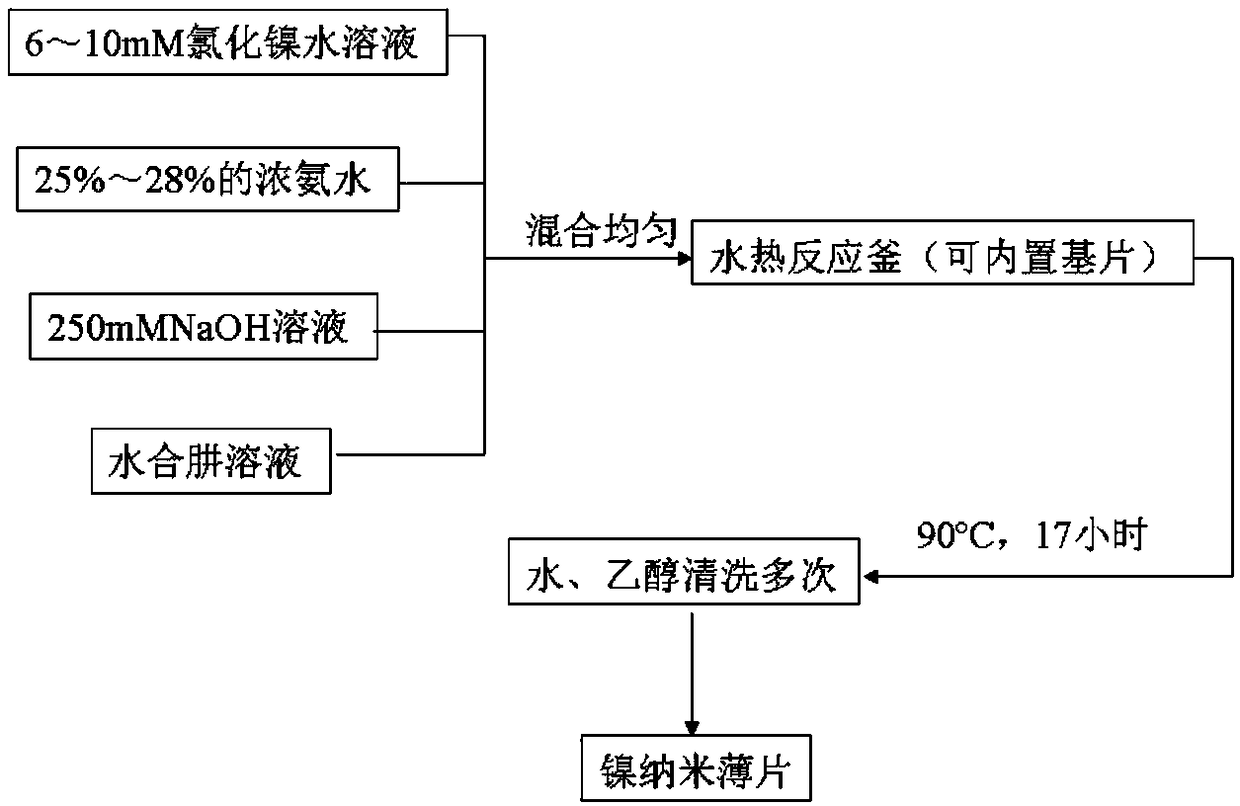

[0036] A method for preparing metal nanosheets, comprising the following steps:

[0037] Step 1, adding 2mL of concentrated ammonia water with a mass fraction of 25% in the nickel chloride solution, then adding 0.05gNaOH, then adding 2mL of a hydrazine hydrate solution with a mass fraction of 80%, stirring and mixing to obtain a mixed solution; The preparation method of nickel solution is: add 0.02g NiCl into 20mL water, stir and dissolve;

[0038] Step 2: Put conductive glass in the lining of the hydrothermal reaction kettle, transfer the mixed solution into the lining of the hydrothermal reaction kettle, seal it, and keep the temperature at 90°C for 14 hours to obtain thick nickel nanometers grown on the substrate. piece;

[0039] Step 3, washing the rough nickel nanosheets repeatedly in pure water and ethanol for several times, and drying to obtain the nickel nanosheets.

[0040] figure 2 with 3 A scanning electron microscope image of the nickel nanosheets prepared in ...

Embodiment 2

[0042] A method for preparing metal nanosheets, comprising the steps of:

[0043]Step 1: Add 0.02g NaOH to the nickel chloride solution, then add 2mL of hydrazine hydrate solution with a mass fraction of 80%, stir and mix evenly to obtain a mixed solution; the preparation method of the nickel chloride solution is: add 0.02g NiCl 20mL water, stir to dissolve;

[0044] Step 2: Put conductive glass in the lining of the hydrothermal reaction kettle, transfer the mixed solution into the lining of the hydrothermal reaction kettle, seal it, and keep the temperature at 90°C for 14 hours to obtain thick nickel nanometers grown on the substrate. piece;

[0045] Step 3, washing the rough nickel nanosheets repeatedly in pure water and ethanol for several times, and drying to obtain the nickel nanosheets.

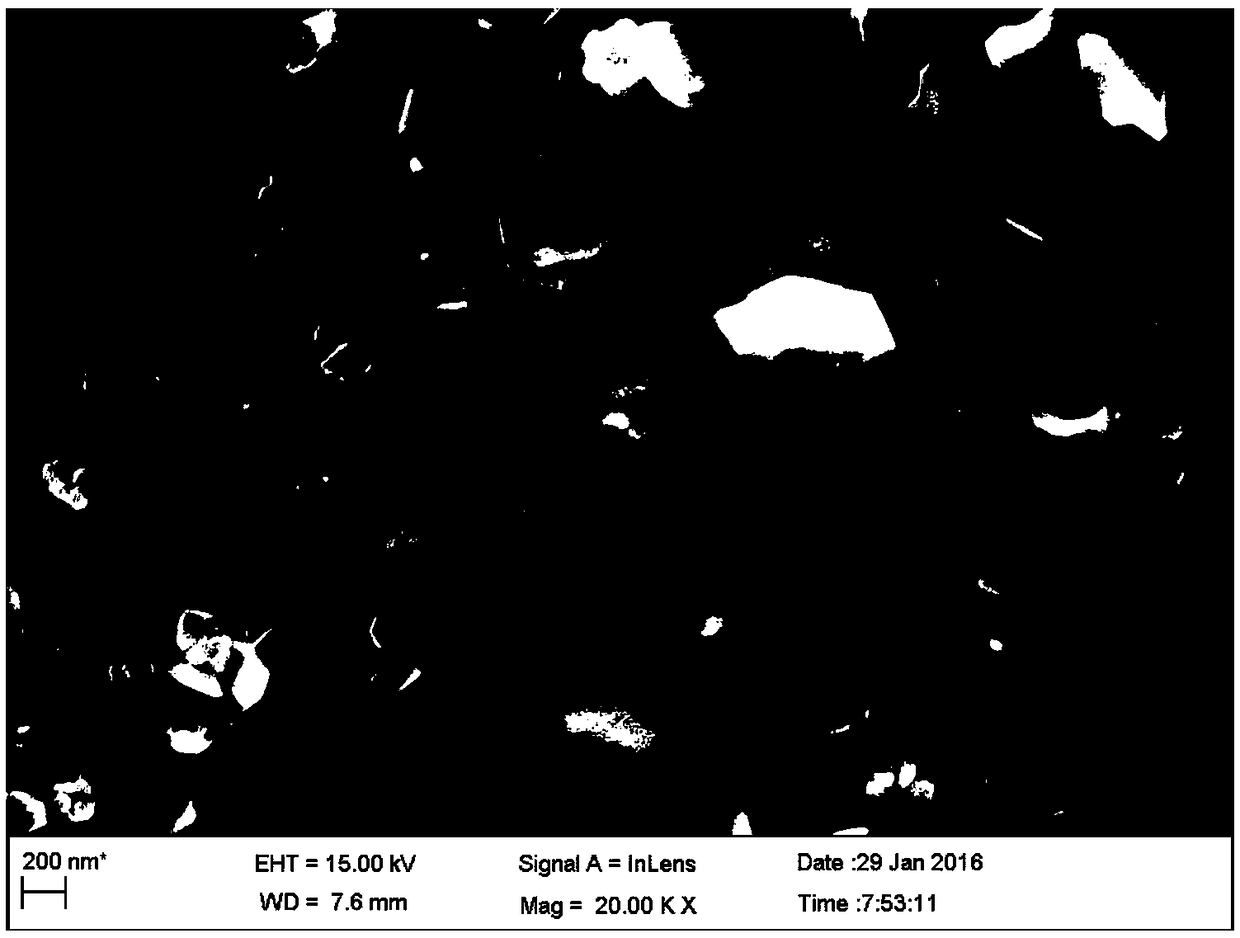

[0046] Figure 4 A scanning electron microscope image of the nickel nanosheets prepared in Example 2 is shown, and the size of the prepared nickel nanosheets is about 100 nm.

Embodiment 3

[0048] A method for preparing metal nanosheets, comprising the following steps:

[0049] Step 1: Add 0.05gNaOH to the nickel chloride solution, then add 2mL of hydrazine hydrate solution with a mass fraction of 80%, stir and mix evenly to obtain a mixed solution; the preparation method of the nickel chloride solution is: add 0.02g NiCl 20mL water, stir to dissolve;

[0050] Step 2: Put conductive glass in the lining of the hydrothermal reaction kettle, transfer the mixed solution into the lining of the hydrothermal reaction kettle, seal it, and keep the temperature at 90°C for 14 hours to obtain thick nickel nanometers grown on the substrate. piece;

[0051] Step 3, washing the rough nickel nanosheets repeatedly in pure water and ethanol for several times, and drying to obtain the nickel nanosheets.

[0052] Figure 5 A scanning electron microscope image of the nickel nanosheets prepared in Example 3 is shown, and the size of the prepared nickel nanosheets is about 100 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com