LED structure with gallium nitride system

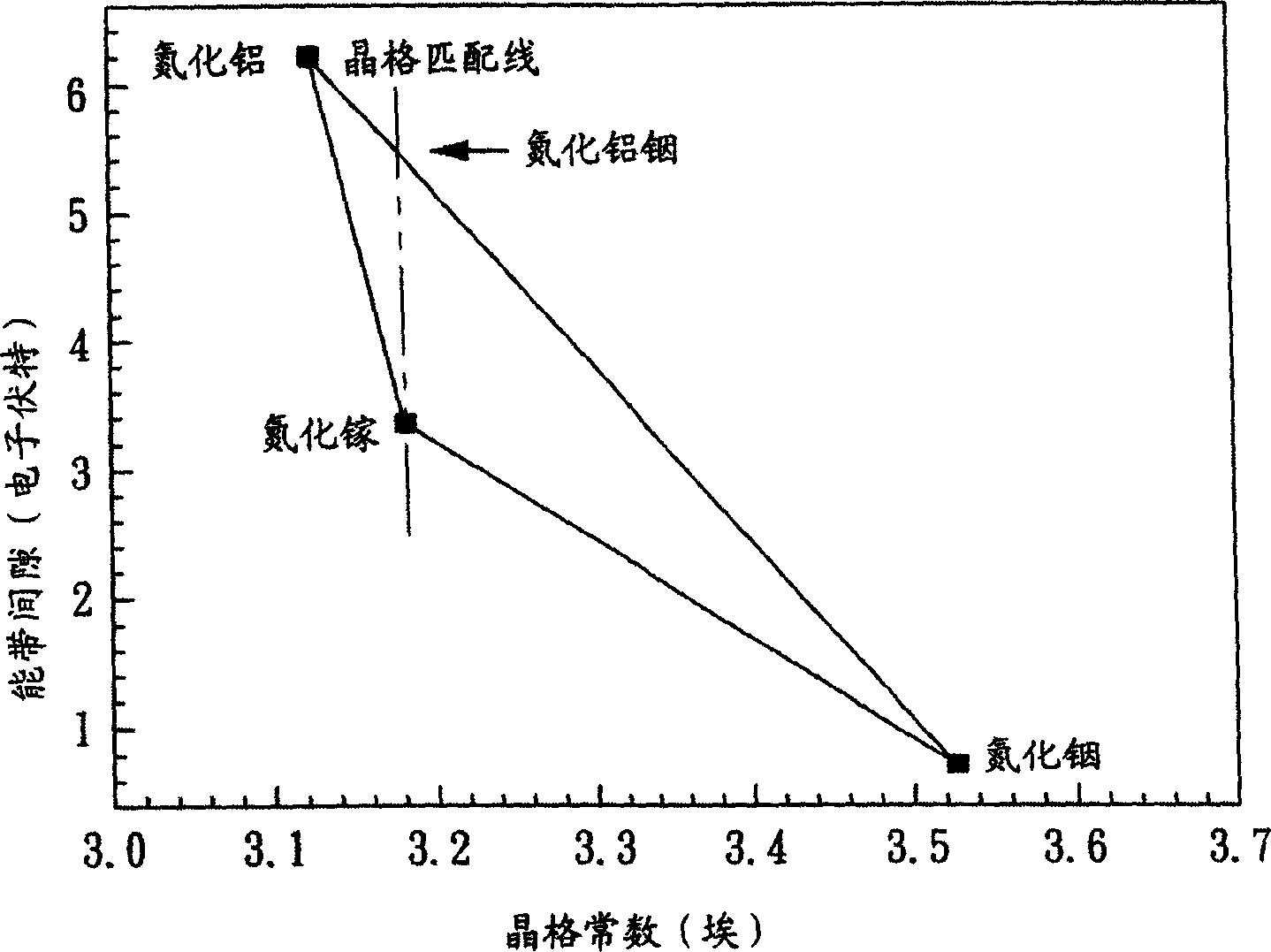

A technology based on light-emitting diodes and gallium nitride, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large gaps in lattice constants, affecting the luminous efficiency of light-emitting diodes, and large mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] The first embodiment of the gallium nitride-based light-emitting diode structure of the present invention includes: a substrate 11, a buffer layer (buffer layer) 12, an n-type gallium nitride (GaN) layer 13, an active light-emitting layer 14, and a p-type cladding layer 15 , and the contact layer 16.

[0031] The substrate 11 is made of aluminum oxide single crystal (Sapphire). A buffer layer (buffer layer) 12 located on the substrate 11 is made of aluminum gallium indium nitride (AlGaN) 1-x-y Ga x In y N), wherein 0≤X1-x In x N), where 0≤X<1. The p-type cladding layer 15 has a thickness ranging from 50 angstroms to 3000 angstroms. The growth temperature of the p-type cladding layer 15 is between 600°C and 1200°C.

[0032] The contact layer 16 on the p-type cladding layer 15 is made of Mg-doped p-type gallium nitride (GaN).

[0033] The first embodiment of the GaN-based LED structure of the present invention may further include an electrode layer 17 located on th...

no. 4 example

[0044] The fourth embodiment of the gallium nitride-based light-emitting diode structure of the present invention includes: a substrate 41, a buffer layer 42, an n-type gallium nitride (GaN) layer 43, an active light-emitting layer 44, a double coating layer 45, and a contact layer 46 .

[0045] The substrate 41 is made of alumina single crystal. The buffer layer 42 on the substrate 41 is made of aluminum gallium indium nitride (AlGaN) 1-x-y Ga x In y N), wherein 0≤X1-x In x N), where 0≤X1-z In z N), where 0≤Z<1. The thickness of the second coating layer 452 is between 50 (Å) to 3000 (Å), and the growth temperature is between 600°C and 1200°C.

[0046] The contact layer located on the double coating layer 45 is made of magnesium (Mg) doped aluminum indium nitride (Al 1-x In x N) p-type gallium nitride (GaN), where 0≤X<1.

[0047] The fourth embodiment of the GaN-based LED structure of the present invention may further include an electrode layer 47 located on the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com