Motor and devive using this

A technology of motors and armatures, applied in the field of motors, can solve problems such as ineffective use of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

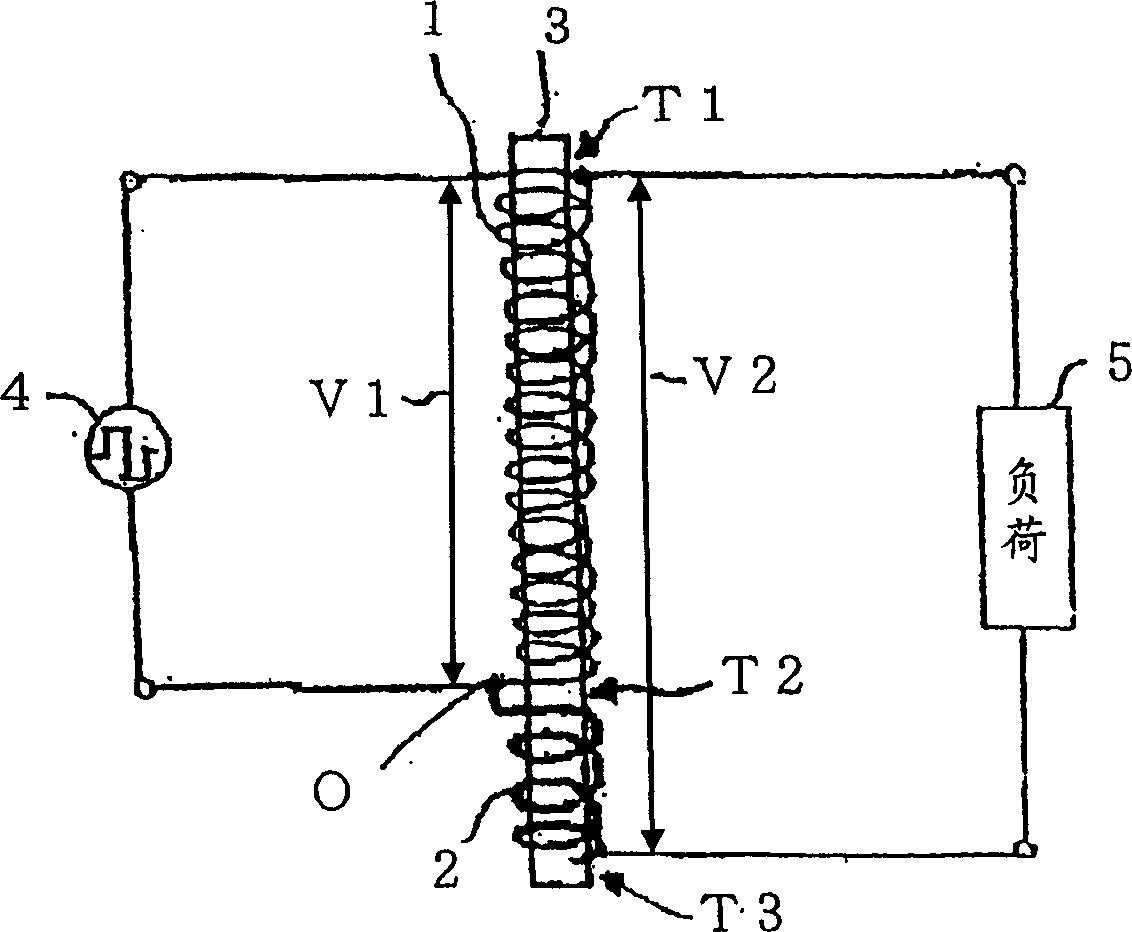

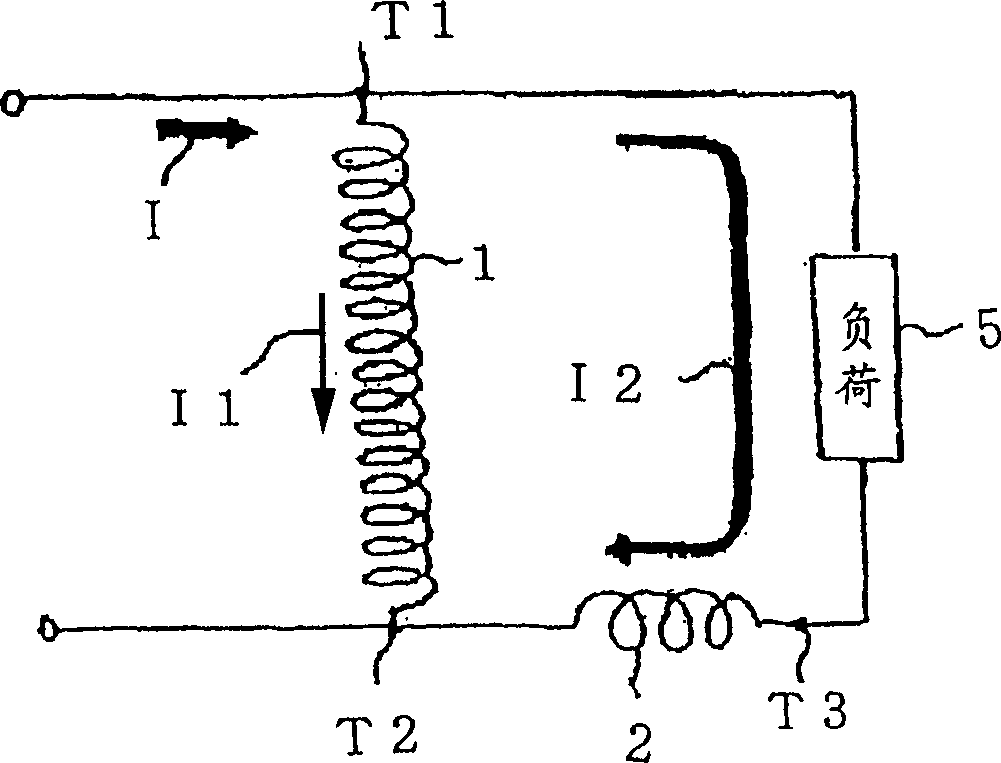

[0121] First, Embodiment 1 of the present invention will be described. figure 2 It is a basic circuit diagram showing the winding structure of two coils 1, 2 wound on a linear iron core used in the linear motor of Embodiment 1 of the present invention. In this embodiment, the coil 1 and the coil 2 are wound around the iron core 3 in the same direction, and the coil 1 and the coil 2 are alternately arranged and connected in parallel. image 3 is equivalent to figure 2 The circuit diagram of coil 1 and coil 2 in the figure 1 The currents I1, I2 flowing in the windings are shown. exist figure 2 Among them, the iron core 3 is a laminated electromagnetic steel sheet having a rod-shaped structure with the same cross-sectional area. Coils 1, 2 have different resistances. For example, on the core 3, a coil 1 made of thin copper wire with a large number of windings and a large resistance value and a coil 2 made of thick copper wire with a small number of windings and wound in t...

Embodiment 2

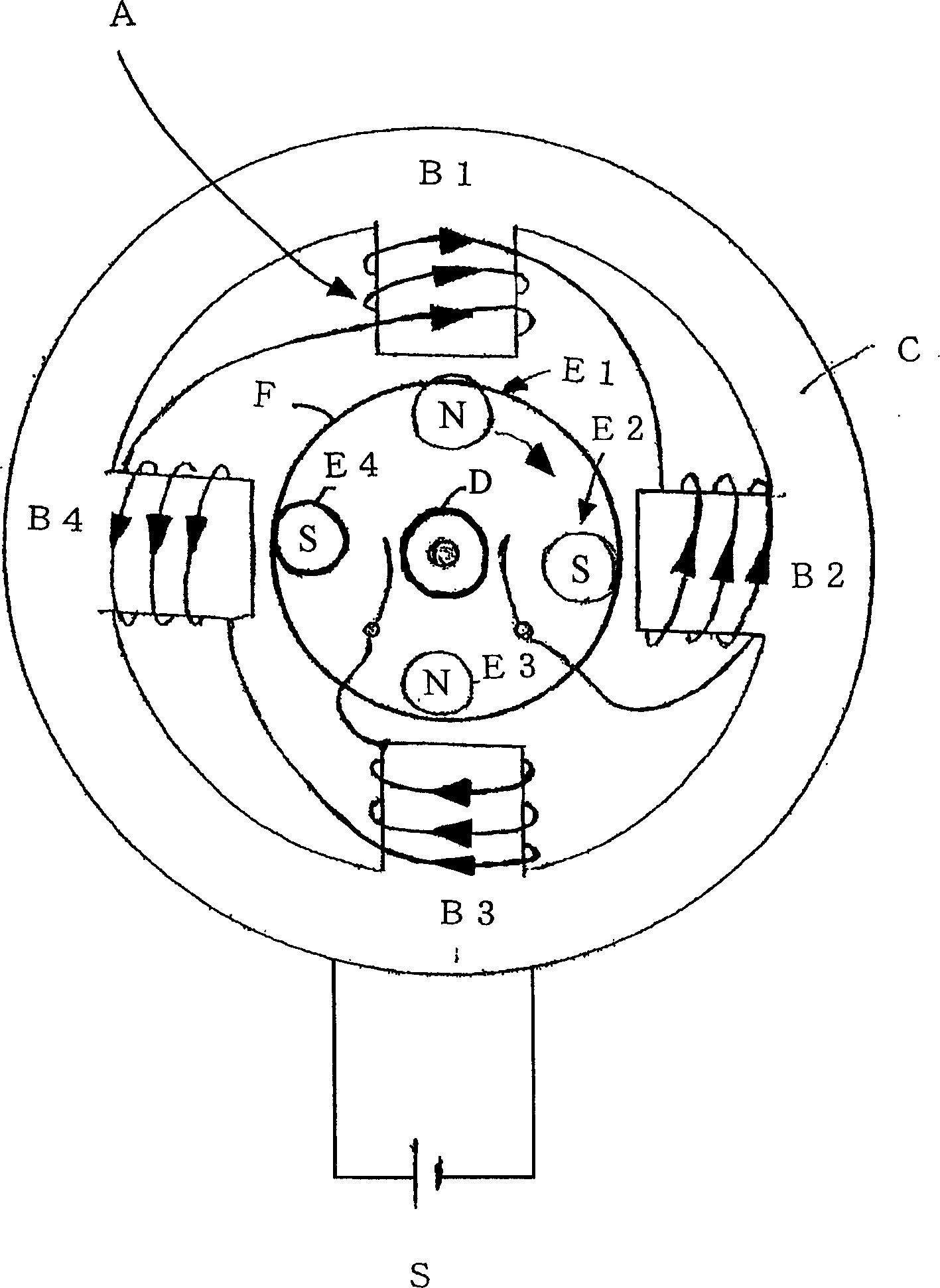

[0132] Next, Embodiment 2 of the present invention will be described. In the above-mentioned embodiment 1, a linear motor is realized, but in the present embodiment 2, a rotary motor using the above-mentioned transformer can be realized.

[0133] Figure 6 It is an assembly diagram of a rotating electric machine 20 composed of a permanent magnet rotor 21 and an annular magnetic circuit armature 24 as a second embodiment of the present invention. In this embodiment, the annular magnetic circuit armature 24 is annular, formed by the circular iron core 23 and the rotor, and is circular. In this example, if Figure 7 As shown, three coils 1 a to 1 c and three coils 2 a to 2 c are alternately wound around the circumference of the iron core 23 . Such as Figure 5 The winding method of coils 1a~1c is series winding, and the winding method of coils 2a~2c is parallel winding. In the embodiment, the coils 1a to 1c are thinner, have more windings than the coils 2a to 2c, and have hi...

Embodiment 3

[0152] Figure 12 It is an assembly diagram for explaining Embodiment 3 of the present invention. The constitution of the present embodiment 3 is that, on the basis of the structure of the embodiment 2, it further has the power generation function, and supplements the lost electric energy such as copper loss and iron loss of the commutator 26 and the annular magnetic circuit armature 24 . The yoke 25 is positioned above the air core coil, the disc is supported by the shoulder 21c of the shaft 21b, and the commutator 26 is supported by the disc. The yoke 25 has the same inclination and size as the permanent magnet rotor 21 and is parallel thereto. The yoke is, for example, iron. While the yoke 25 is rotated by the permanent magnet rotor 21, an applied torque is generated in the yoke by eddy current. Figure 12 It is an independent figure of the motor of Example 3 of this invention. in addition, Figure 13 to represent Figure 12 Diagram showing the positional relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com