Infrared irridiation crosslinked polyethylene plastic for pipe, wire and cable and its preparing method

A cross-linked polyethylene, wire and cable technology, applied in applications, household utensils, tubular objects, etc., can solve the problems of complex process, large equipment investment, large equipment footprint, etc., to improve cross-linking quality, improve activity, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 is used for pipes in occasions with certain requirements on mechanical properties.

Embodiment 2

[0040] Example 2 is used for pipes in occasions with higher performance requirements.

[0041] Infrared irradiation cross-linked polymer

Composition of vinyl plastic

Dosage (parts by weight)

Example 3

Example 4

Example 5

Example 6

Control, unirradiated

polyethylene resin

100

100

100

100

100

peroxide crosslinking agent

0.5

0.8

0.5

0.8

0

Auxiliary crosslinking agent

0.2

0.2

0.2

0.2

0

0.1

0.1

0.1

0.1

0

0.02

0.05

0.03

0.05

0

filler

0

0

10

40

0

[0042] The peroxide crosslinking agent in above-mentioned embodiment 3~6 is di-tert-butyl peroxide, and antioxidant is the 1010 of CIBA company namely tetrakis [3-(3,5-di-tert-butyl-4-hydroxyl phenyl) ) propionic acid] pentaerythritol ester, the auxiliar...

Embodiment 7

[0046] Embodiment 7 (special equipment for infrared radiation)

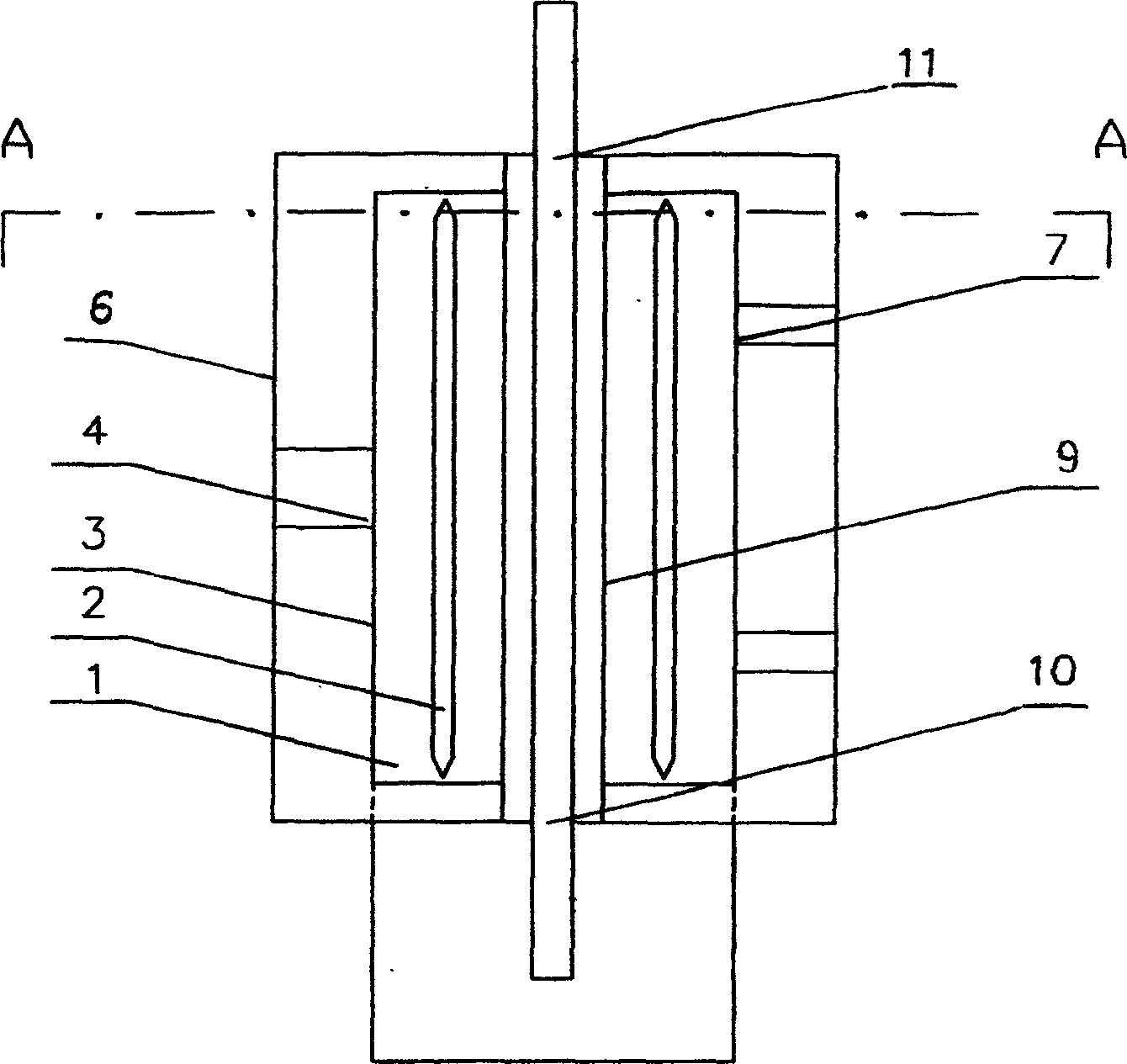

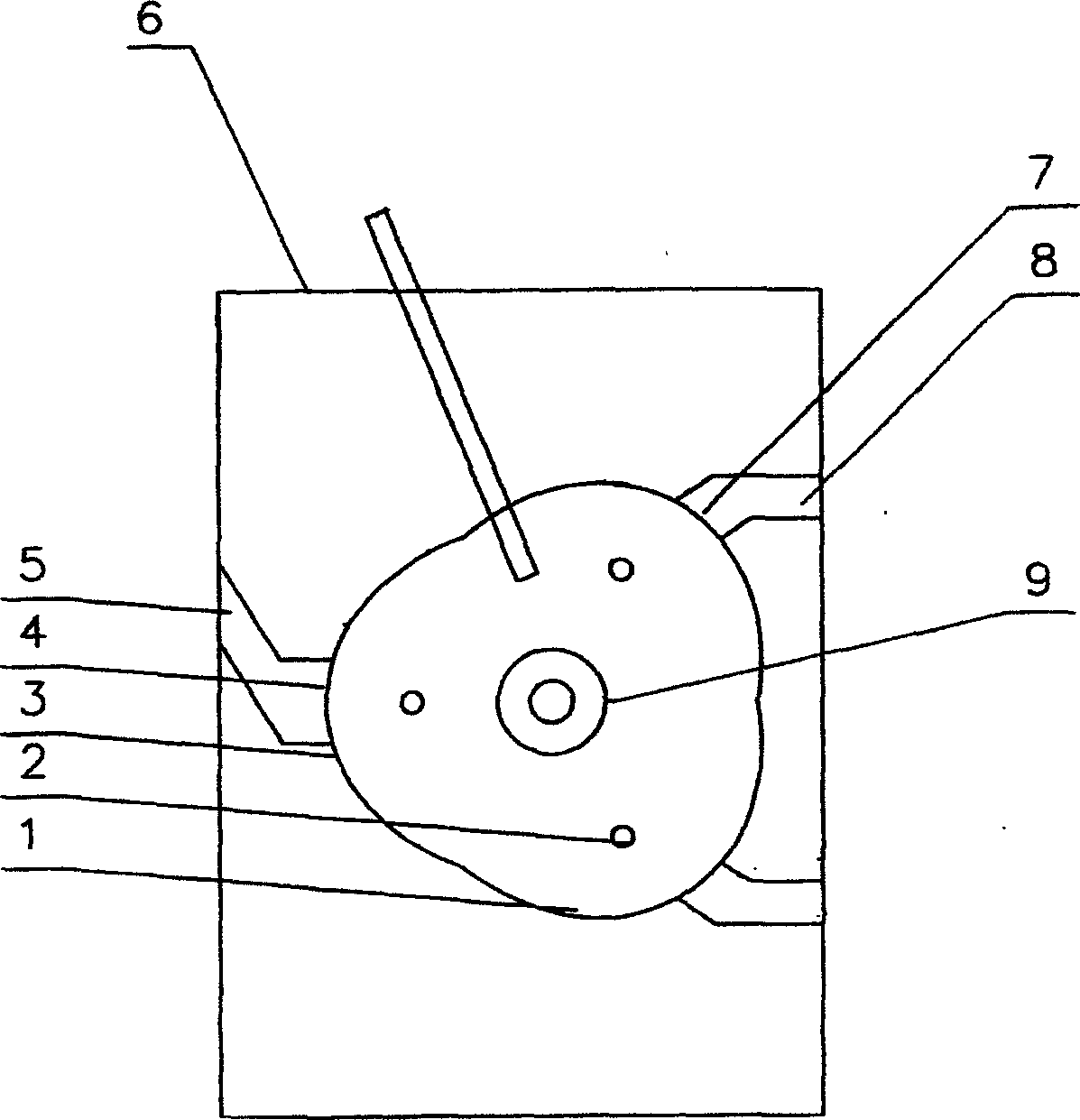

[0047] see figure 1 and figure 2 , the special equipment for the preparation method of infrared radiation cross-linked polyethylene plastics for pipes, wires and cables, consisting of infrared radiation box [1] and protective cover [6], pipes, wires and cables inlet [10] and outlet [ 11], which is characterized in that: the infrared radiation camera [1] is composed of a reflector [3], three evenly distributed infrared lamps [2], polyethylene pipes, wire and cable isolation layers [9], and the reflector [3] ]’s cross-section is a petal shape composed of three ellipses with a common focus, three infrared lamps [2] are respectively fixed on the respective focal points of three oval petal-shaped reflectors [3], polyethylene pipes, wires The cable isolation layer [9] is set on the common focus of 3 oval petal-shaped reflectors [3], and the reflector [3] is provided with an air outlet [4] and an air inlet [7], and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com