Impellor used for centrifugal pump and centrifugal type fan

The technology of a centrifugal fan and a centrifugal pump is applied to the impeller. In the field, it can solve the problems of low operating efficiency, increased friction surface, and consumption of useless work, so as to achieve the effects of improving operating efficiency, increasing vacuum degree, and accelerating flow velocity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

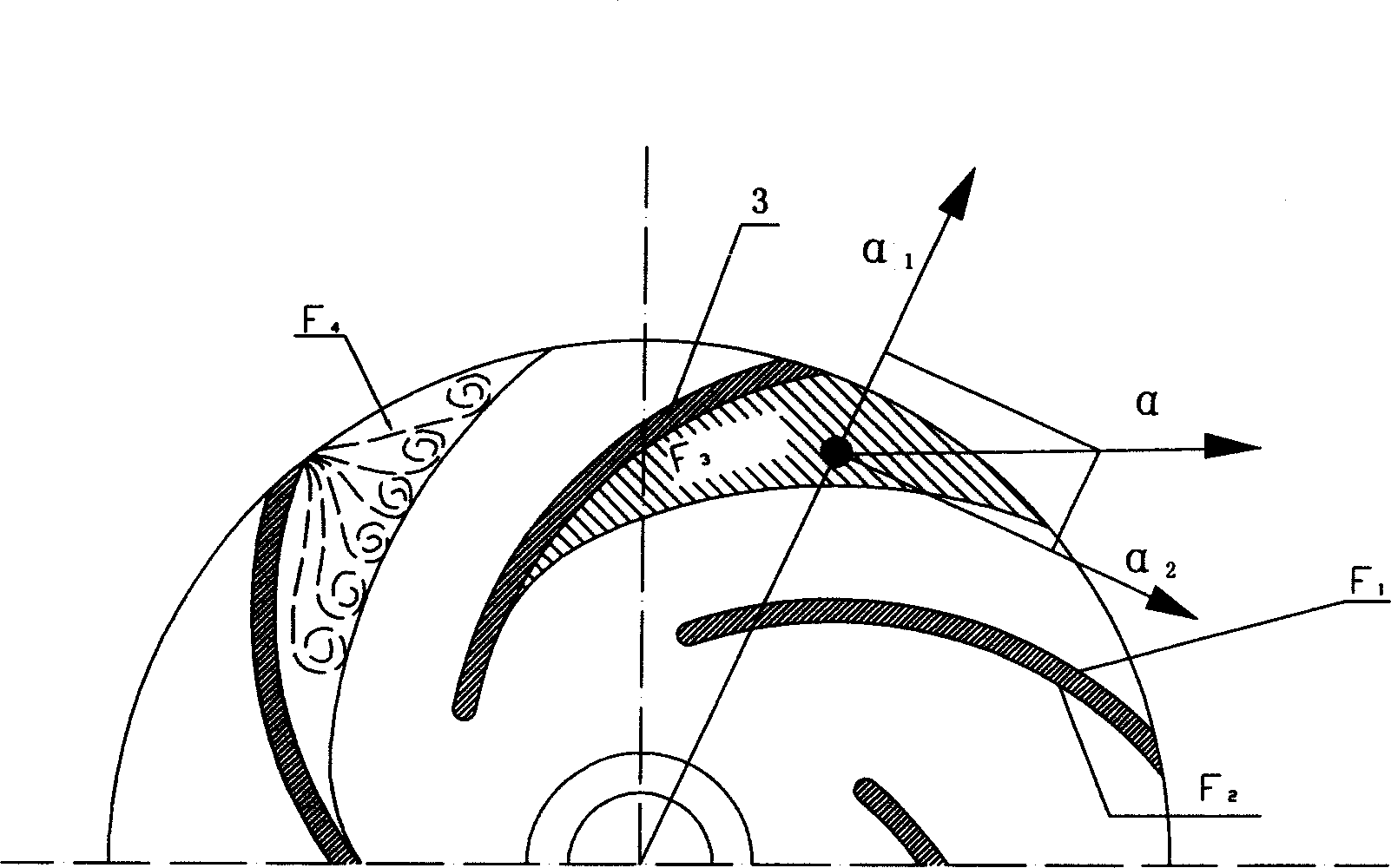

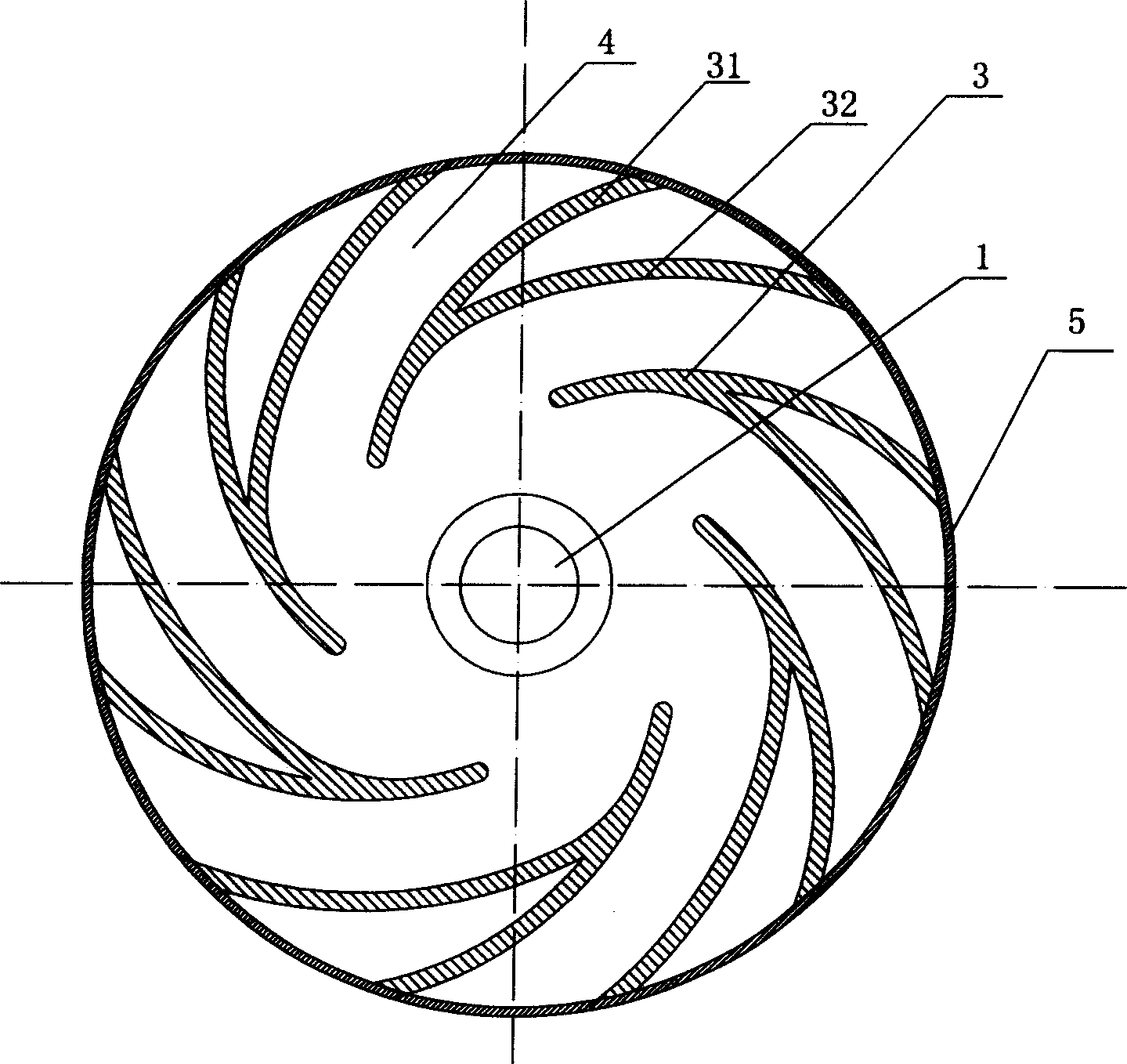

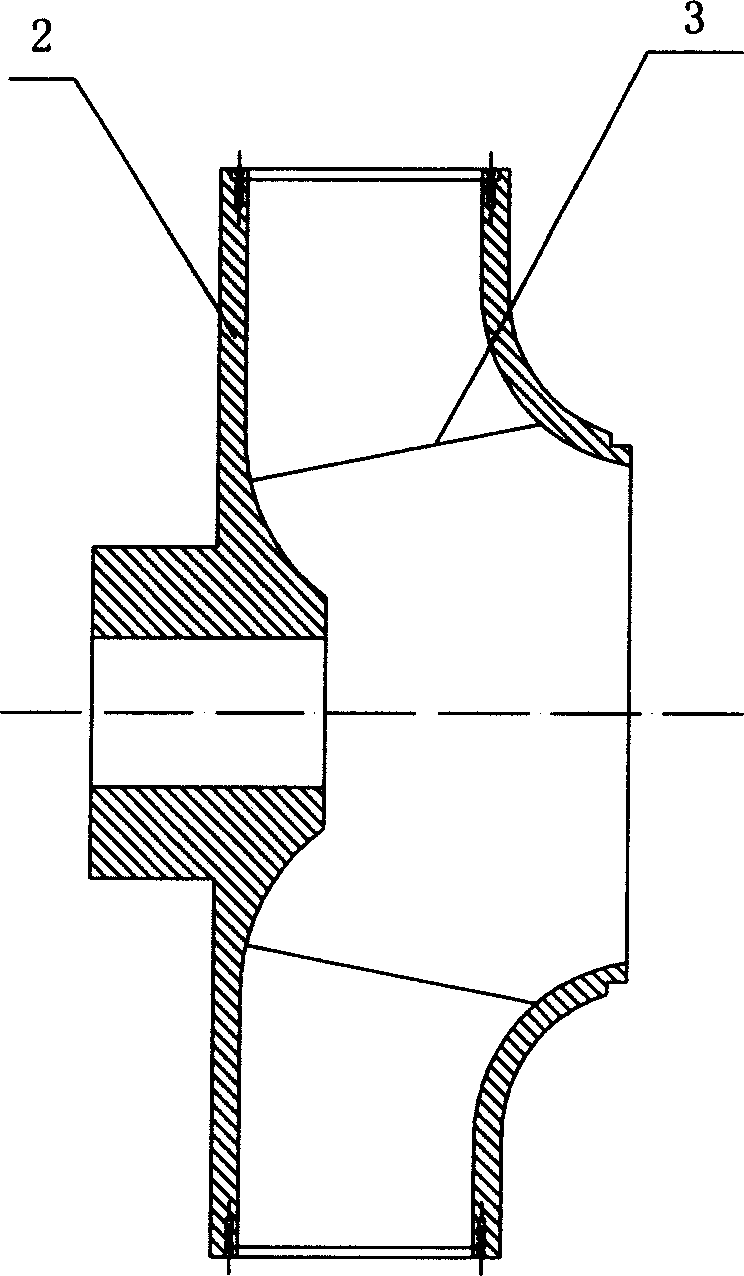

[0026] Such as figure 2 and image 3 As shown, the impeller used for centrifugal pumps and centrifugal fans of the present invention includes a wheel housing 1, a web 2, and two or more blades 3 installed on the web 2, and between adjacent blades 3 A flow channel 4 is formed between them. The blade 3 is composed of a main blade 31 and an auxiliary blade 32. The main blade 31 and the auxiliary blade 32 are overlapped at the small radius end of the impeller. As the radius of the impeller increases, the main blade 31 and the auxiliary blade The distance between 32 gradually widens, and the main blade 31 and auxiliary blade 32 are connected by a sealing plate 5 at the largest radius of the impeller. In a preferred embodiment, the overlapping thickness of the main blade 31 and the auxiliary blade 32 at the small radius end of the impeller is equal to the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com