Manufacturing method of coppor alloy shaft bushing for large grinding machine

A production method and technology of copper alloy, applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve problems such as working with diseases, difficulty in replacing bearing bushes, and inability to cast large-diameter bearing bush blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

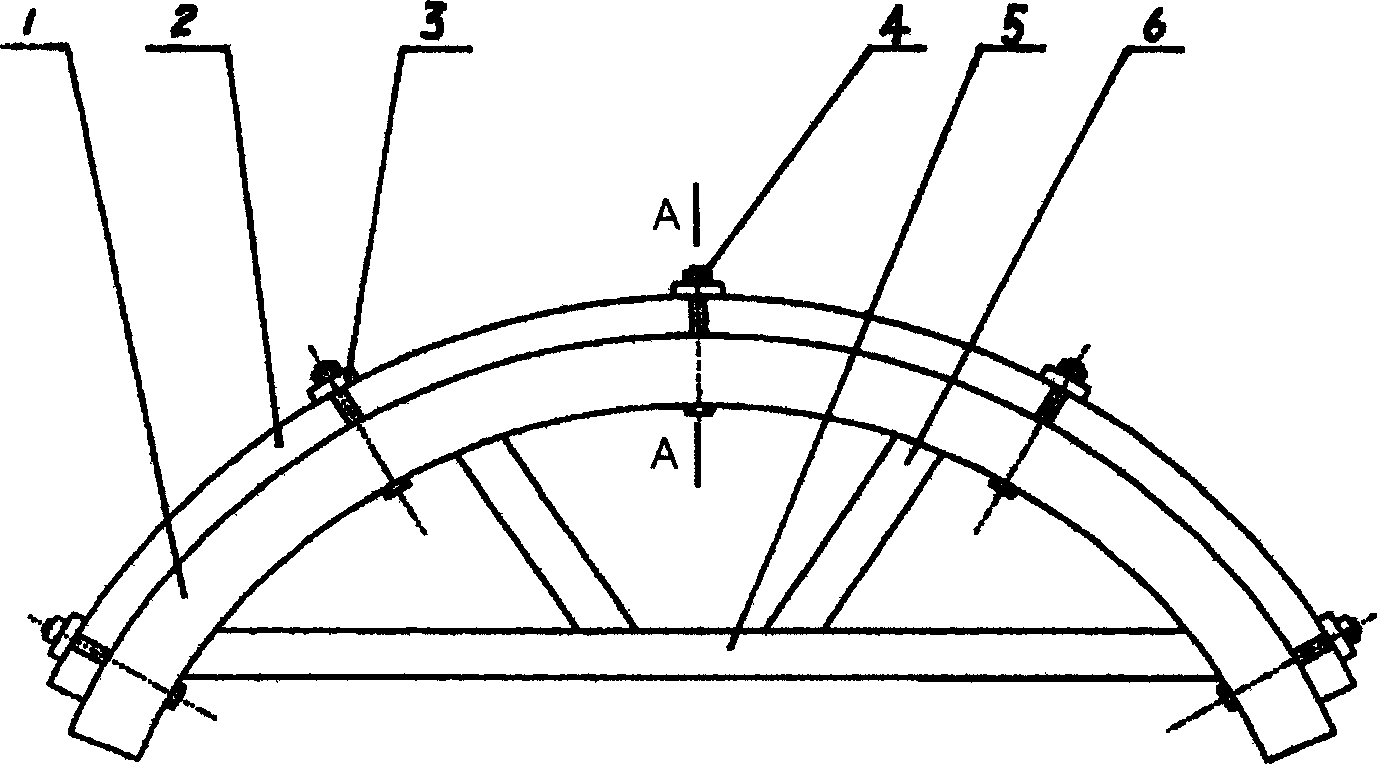

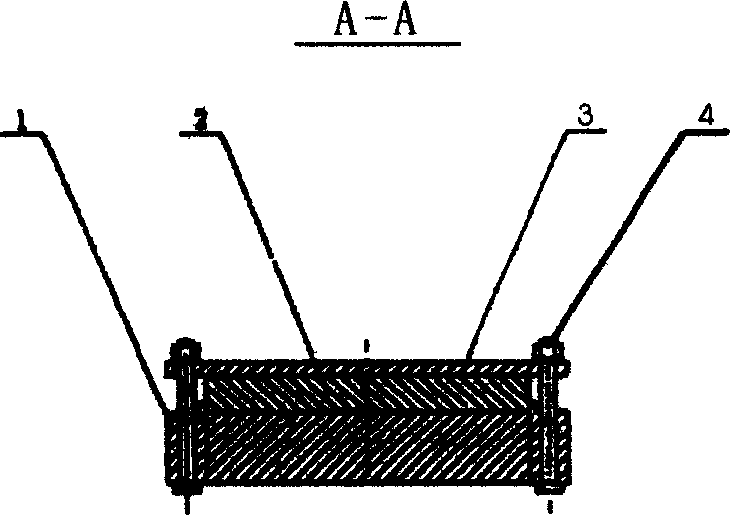

[0015] When making and processing bearing bushes, choose a hot-rolled aluminum bronze plate with a suitable thickness of QAL9-4, which contains 8.0-10.0% aluminum, 2.0-4.0% iron, 0.01% phosphorus, and 1% zinc. , the rest is copper content; processed to the length and width dimensions suitable for the process requirements; roll the sheet material into a suitable arc size with a plate rolling machine; the fitter checks and repairs the circle of the arc blank by lofting on the platform arc size and torsion, so that it meets the requirements for machining margins; the bearing bush blank (2) is supported and fixed by a supporting device composed of supporting arch beams (1), supporting beams (5) and inclined beams (6), After being clamped and fixed by the splint (3) and the fastening bolt (4), it is sent to the heating furnace for aging treatment to eliminate the internal stress caused by the coiling. The aging temperature is 540°C-560°C and the time is 24h; it is processed by speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com