Homogeneous catalysis low boiling point olefin hydrogen peroxide continuous reaction method and system

A homogeneous catalysis, low boiling point technology, used in organic chemistry methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as pollution, low reaction system efficiency, and co-product environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

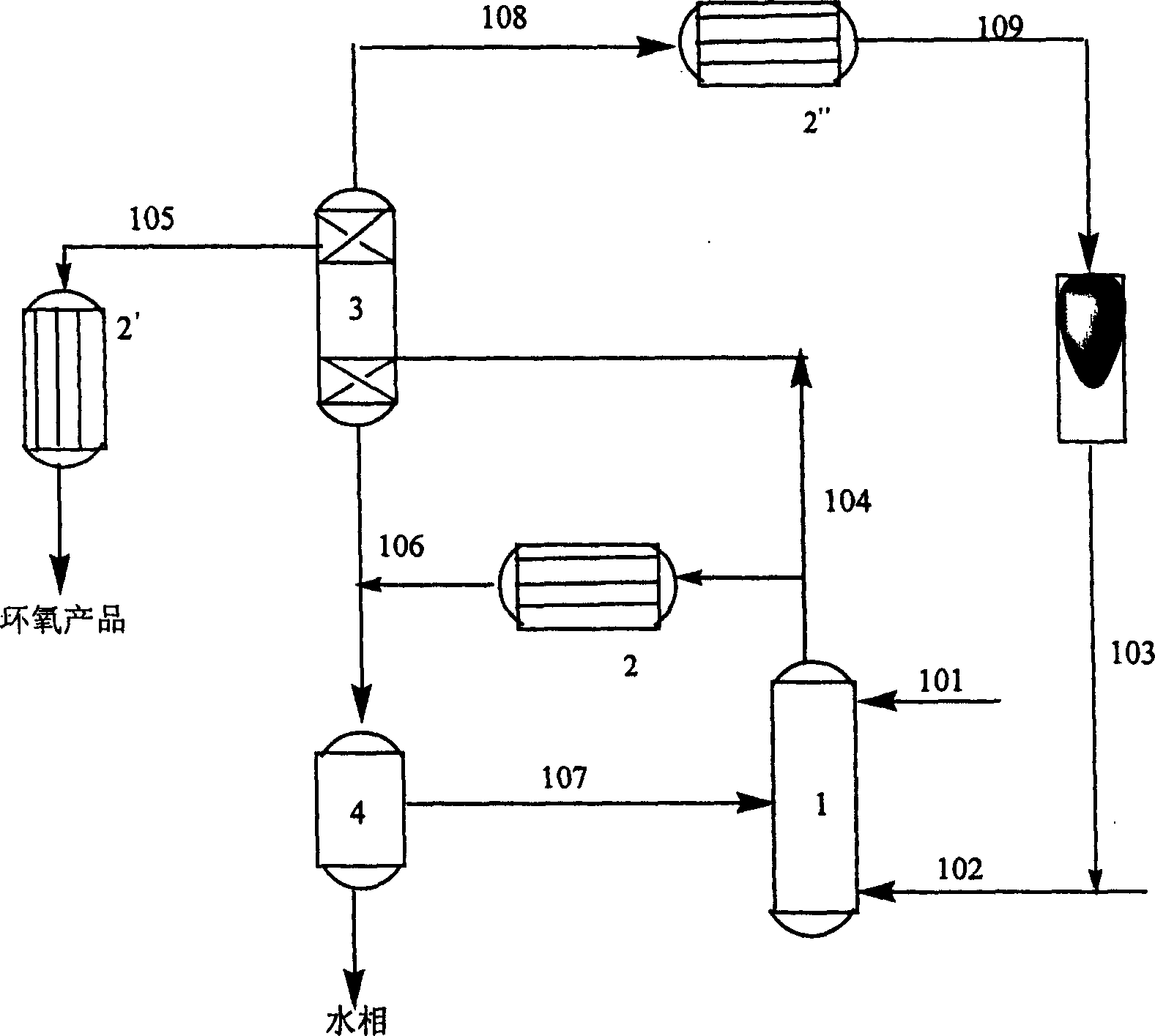

[0022] Example 1. Add 2.5 kg of hydrogen peroxide with a concentration of 30% to the reactor 1 of preloaded 70L solvent (tributyl phosphate and benzene mixed solvent) and 300g of catalyst through pipeline 101, heat up to 80°C, and pass the added hydrogen peroxide through benzene The water is taken out of the system through the pipeline 104, passes through the first condenser 2 (the temperature of the first condenser 2 is 50° C.), enters the water-oil separator 4, and benzene flows back into the reactor 1 through the pipeline 107. Then, be warming up to 85 ℃, control the flow rate of isobutylene to be 30.3mol / h, the flow rate 2kg / h of the hydrogen peroxide of 30% concentration, enter reactor 1 through pipeline 102 and 101 respectively, unreacted olefin, the epoxide of generation, Water and benzene enter rectification tower 3 through pipeline 104, and unreacted olefins pass through pipeline 108 from rectification tower 3 to the third condenser 2" (the temperature of this condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com