Vapor deposition apparatus

A vapor deposition and gas flow channel technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems affecting crystal growth, uneven thickness, uneven crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

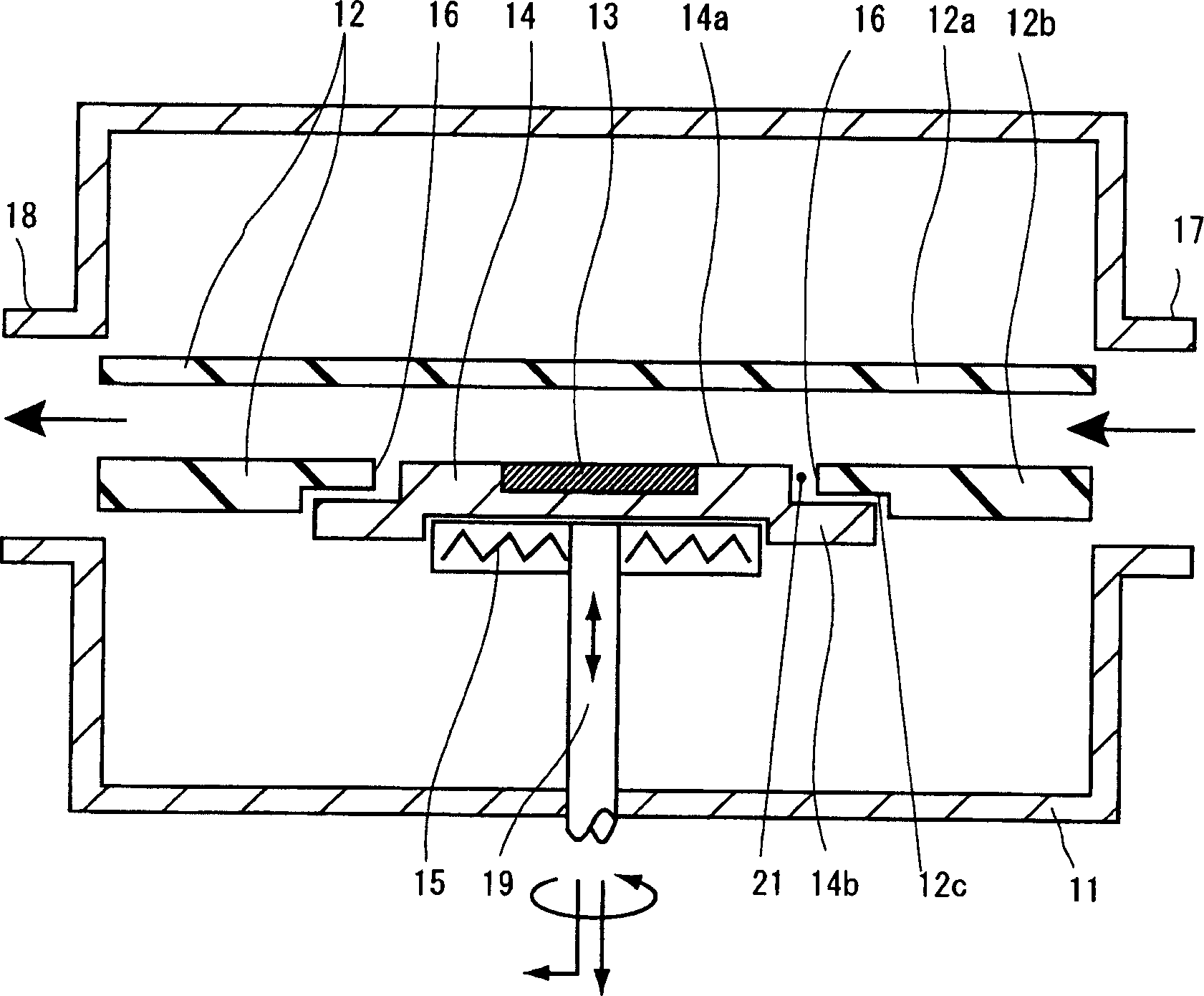

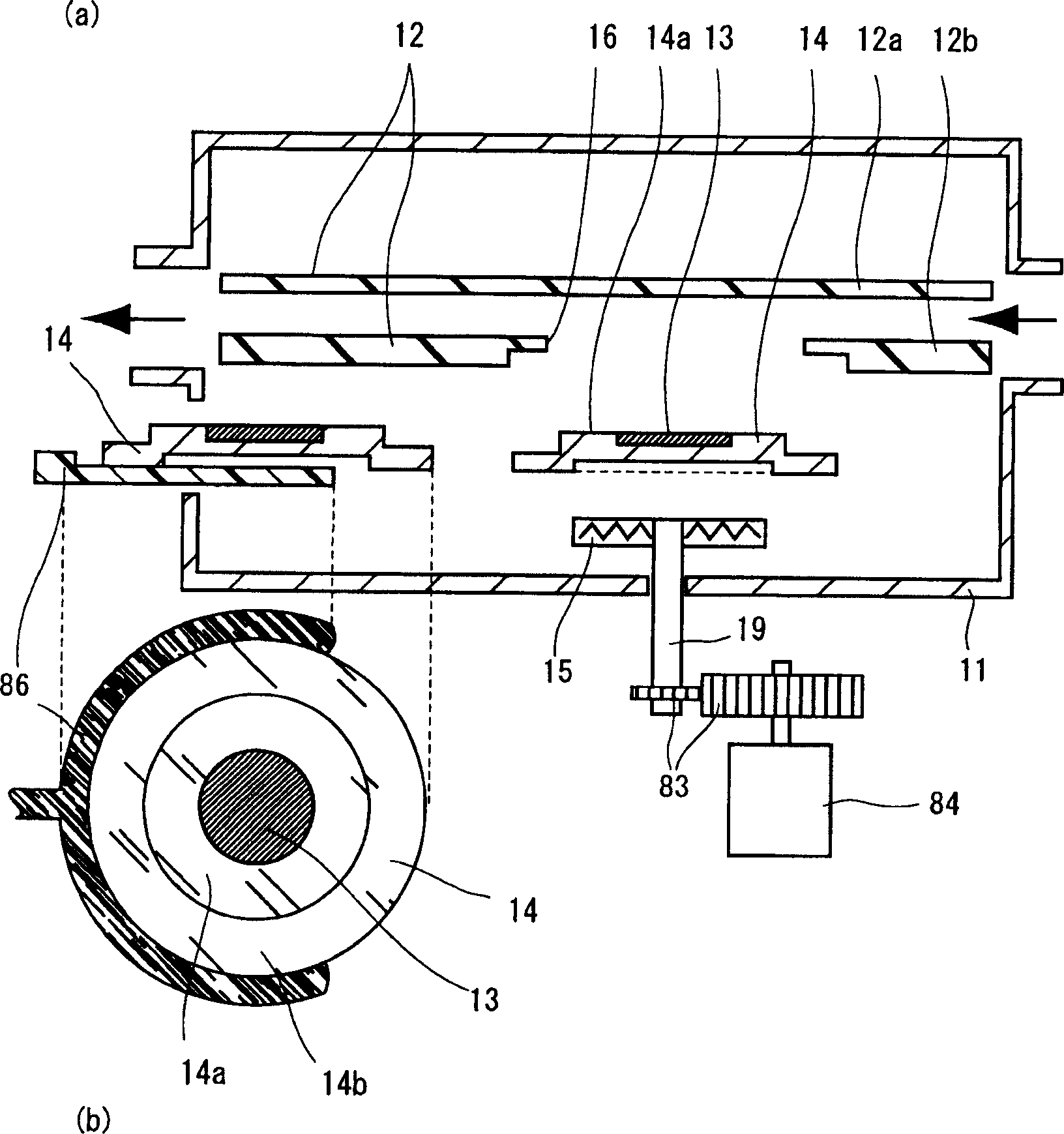

[0048] figure 1 is a cross-sectional view of the vapor deposition apparatus of Embodiment 1. This vapor deposition apparatus has, in a reaction chamber 11, a gas flow path 12 for efficiently supplying a source gas onto a substrate 13, a substrate holding member 14 for holding the substrate 13, and a heating substrate holding member 14 in a reaction chamber 11 as in a conventional apparatus. Heater 15. The airflow channel 12 has an upper wall 12a and a lower wall 12b. The source gas flows from the gas supply hole 17 to the gas outlet 18 in parallel to the substrate 13 through the gas flow channel 12 . The lower wall 12 b of the air flow passage 12 has an opening portion 16 . The substrate holding surface 14 a of the substrate holding member 14 is fitted into the opening portion 16 while forming a space 21 between the opening portion 16 and the substrate holding member 14 . The substrate 13 and the substrate holding surface 14 a of the substrate holding member 14 are in con...

Embodiment approach 2

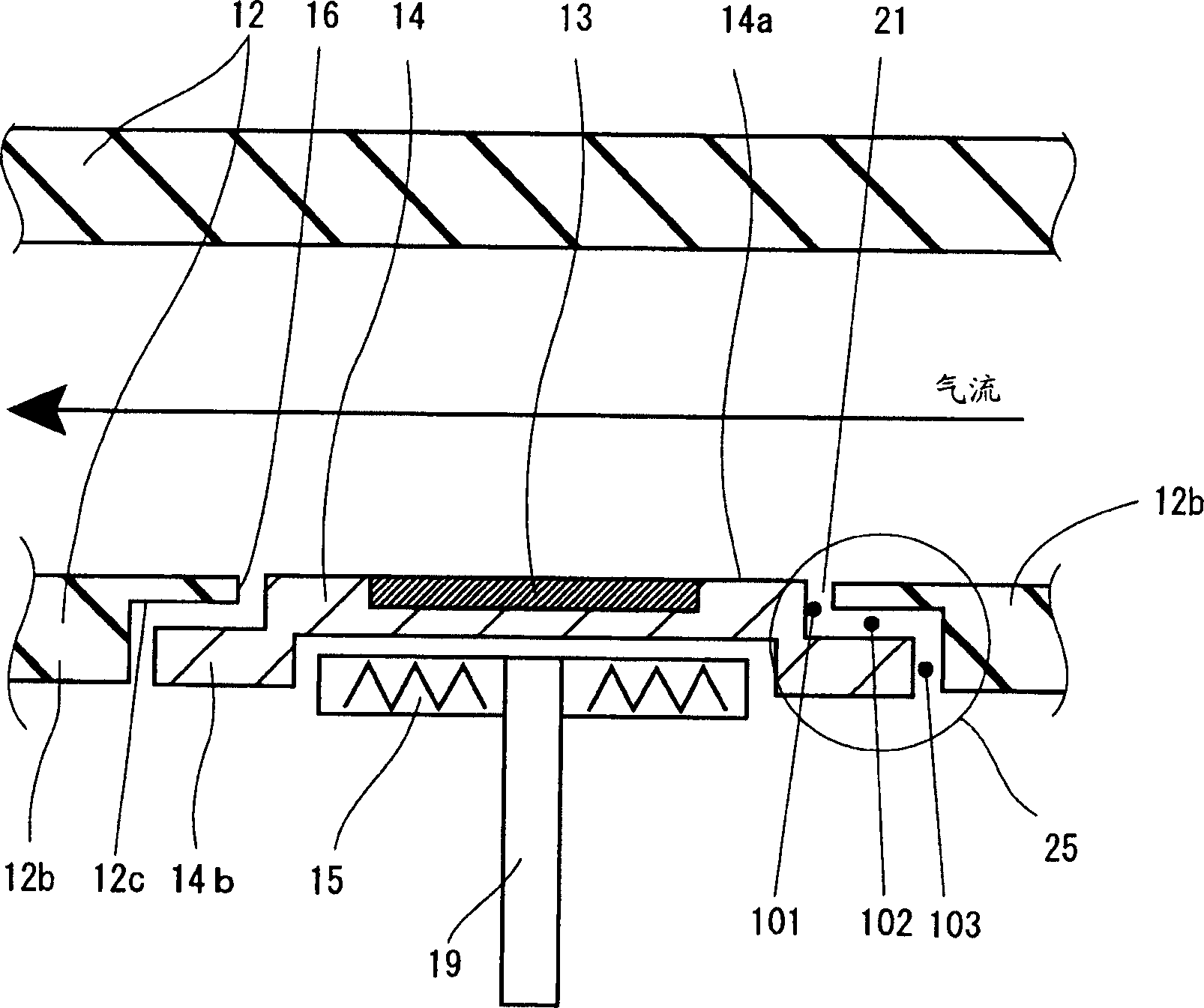

[0062] Figure 6is a partially enlarged cross-sectional view assembling a gas flow channel and a substrate holding member according to Embodiment 2 of the present invention. As shown, in this embodiment, the means for reducing gas leakage consists of a laterally protruding edge 14b from the side wall of the substrate holding member 14 when the substrate holding face 14a of the substrate holding member 14 is in the loading opening. In the state in the portion 16, a space 21 is formed between the edge 14b of the air flow channel 12 and the lower wall 12b at the same time. The lower wall 12b of the airflow channel 12 is of conventional design. That is, only the disc-shaped substrate holding member 14 provided with the edge 14b disposed at its periphery forming the hole structure 25 defined by the opening portion 16 of the gas flow path 12 and the substrate holding member 14 is provided. In this case, the space 21 formed between the hole portion 16 of the gas flow path 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com