Technological process and apparatus of serial gas stripping inner circulation reactor

A reactor and internal circulation technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of substandard ammonia nitrogen concentration in effluent, insufficient nitrification reaction time, and reduced treatment efficiency , to achieve the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

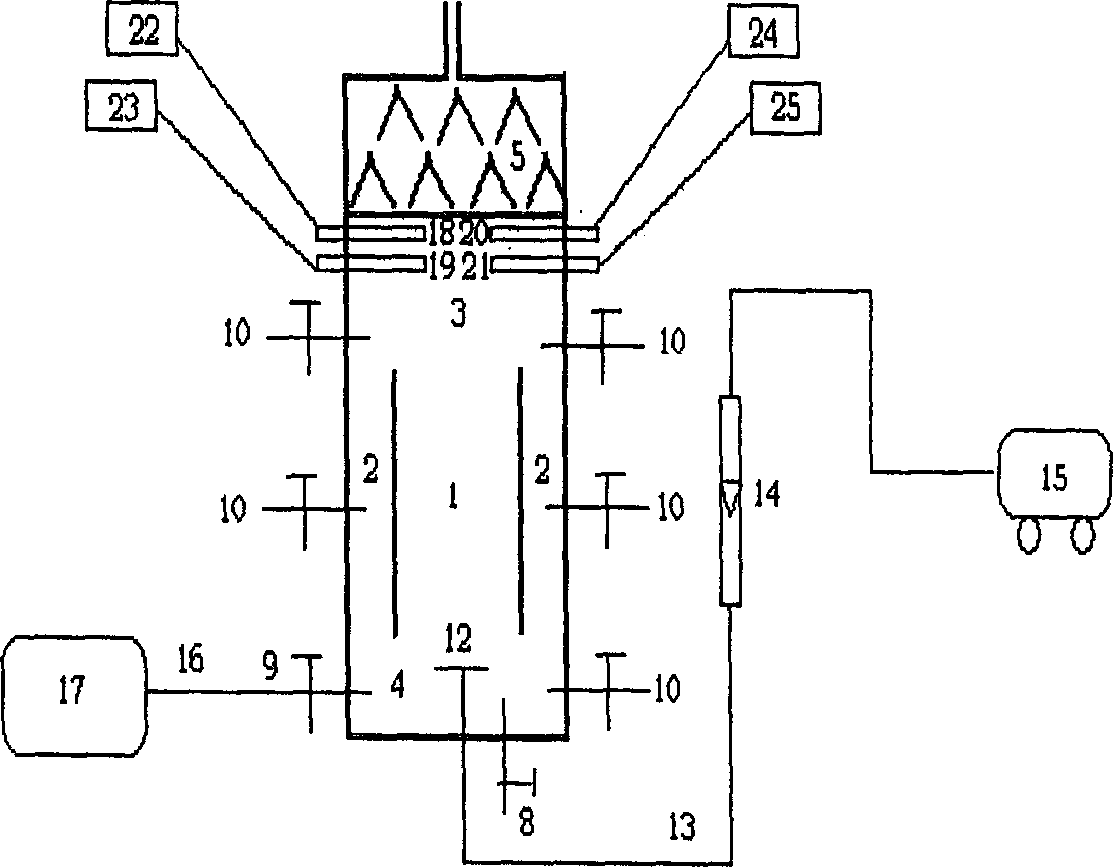

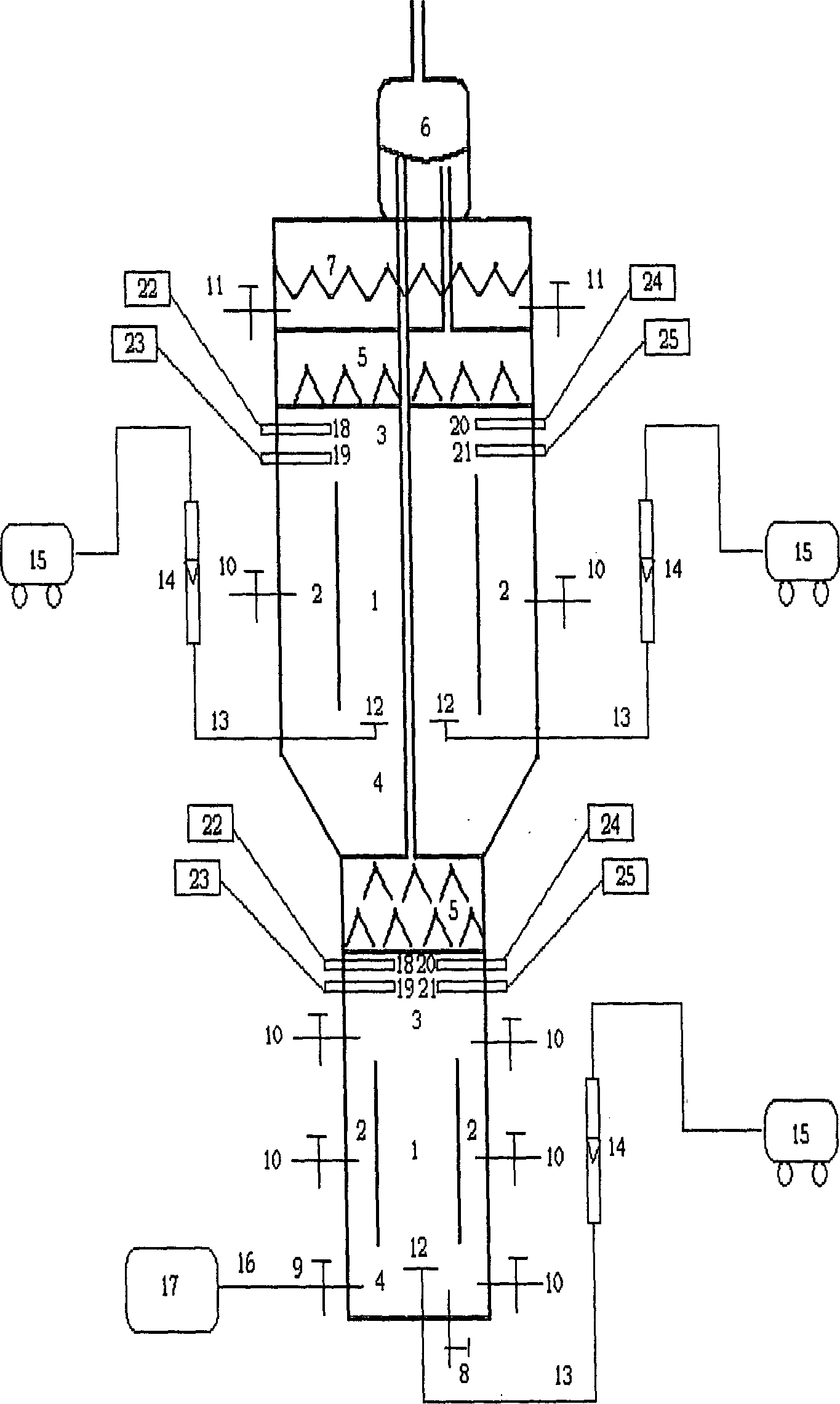

[0025] Attached below figure 1 , 2 A further detailed description will be given to the specific embodiments of the present invention.

[0026] The air-lift internal circulation reactor process in series consists of two air-lift internal circulation reactors connected in series, which are respectively named the upper air-lift internal circulation reactor and the lower air-lift internal circulation reactor. The two-stage reactors are connected by flanges.

[0027] The specific implementation of the air-lifting internal circulation reactor in series is as follows:

[0028](1) The raw sewage enters the lower air-lift internal circulation reactor through the water pump 17 for aeration and oxygenation, the compressed air is delivered by the compressed air pipeline 13, the air flow meter 14 controls the gas flow rate, and the aeration device 12 flows into the reactor. Uniform oxygen supply; DO probe 19 and DO measuring and controlling instrument 23 detect changes in dissolved oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com