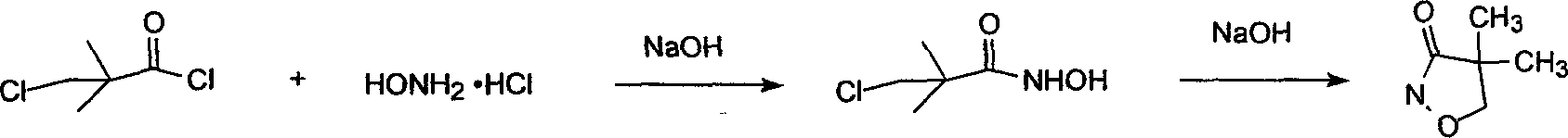

Method for synthesizing 4, 4-dimethyl-iso-xazole-3-one

A technology of dimethylisoxazole and a synthetic method, applied in 4 fields, can solve problems such as low yield, and achieve the effects of reducing three wastes and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Add 400kg of water, 850kg (10kmol) of dichloromethane, 177kg (2.5kmol) of hydroxylamine hydrochloride, 1kg of catalyst crown ether into the reaction kettle, start stirring, add 316kg (2kmol) of chlorinated pivaloyl chloride dropwise, and control the temperature to be lower than 10- 30℃, the dripping time is 2 hours, then sodium hydroxide is dripped to control the pH value between 6-10, the dripping time is about 4 hours, after the addition, continue to stir for 1 hour, stop stirring, and let stand for 1 hour. Separate layers, extract twice, and distill off dichloromethane to obtain 4,4-dimethylisoxazol-3-one, with an average yield of more than 95% and a content of more than 90%.

Embodiment 2

[0011] A method for synthesizing 4,4-dimethylisoxazol-3-one, taking 70kg (1kmol) of hydroxylamine hydrochloride, using crown ether as a catalyst, and using a mixed liquid of 284kg (3.33kmol) of dichloromethane and 300kg of water as a catalyst Solvent, control the reaction temperature to 0-30℃, add chloropivaloyl chloride dropwise for 2 hours, add 158kg (1kmol) dropwise, and then add sodium hydroxide dropwise for 2 hours, keep the solution pH = 6-10, then stir for 1 hour Then stand for separation, extract with dichloromethane, and desolvate to obtain the product; the amount of catalyst is 0.2% of the weight of chloropivaloyl chloride.

Embodiment 3

[0013] Synthetic method of 4,4-dimethylisoxazole-3-one, taking 1.4 kmol of hydroxylamine hydrochloride, using polyethylene glycol-600 as a catalyst, and using a mixed liquid of 850 kg (10 kmol) of dichloromethane and 300 kg of water as a solvent Control the reaction temperature at 0-30℃, add chloropivaloyl chloride for 3 hours, add 158kg (1kmol) dropwise, and then add sodium hydroxide dropwise for 5 hours, keep the solution pH = 6-10, then stir and react for 3 hours Stand to separate the layers, extract the water layer with dichloromethane, and desolvate to obtain the product; the amount of the catalyst is 5% of the weight of chloropivaloyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com