Copper-free wires for gas-shielded arc welding

A gas shielding, copper-free technology, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of blocking the contact tip, unstable arc, increasing lubricant residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments are described in detail below with reference to the accompanying drawings.

[0020] As mentioned above, although the surface of copper-free welding wire needs to have special properties in order for the welding wire to stably contact the contact tip, conventional techniques have proposed methods to make the welding wire form the following properties, and these methods are limited to the surface roughness of the welding wire surface , specific surface area, etc. are controlled within a predetermined range, but these methods cannot guarantee stable contact between the contact tip and the welding wire.

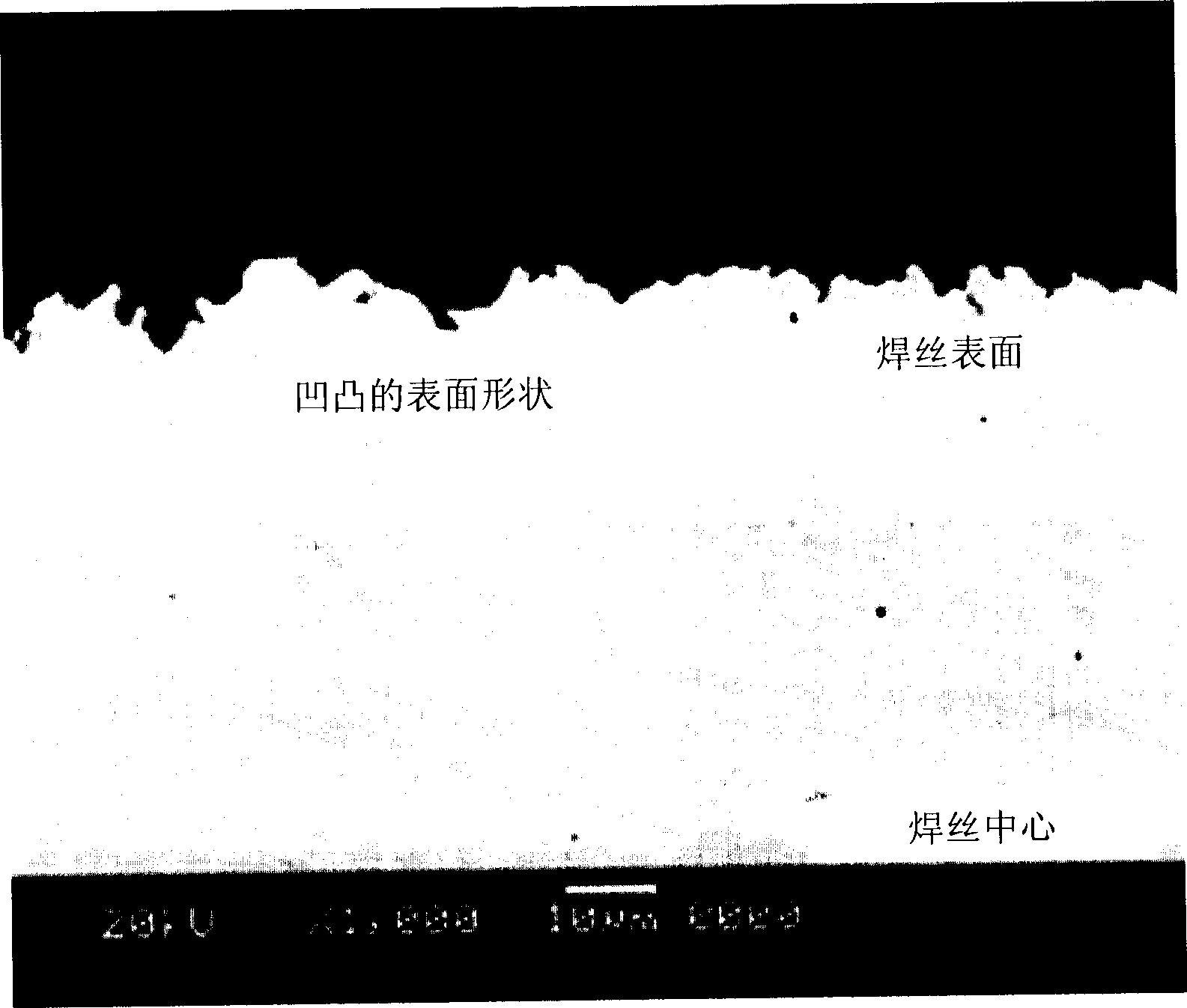

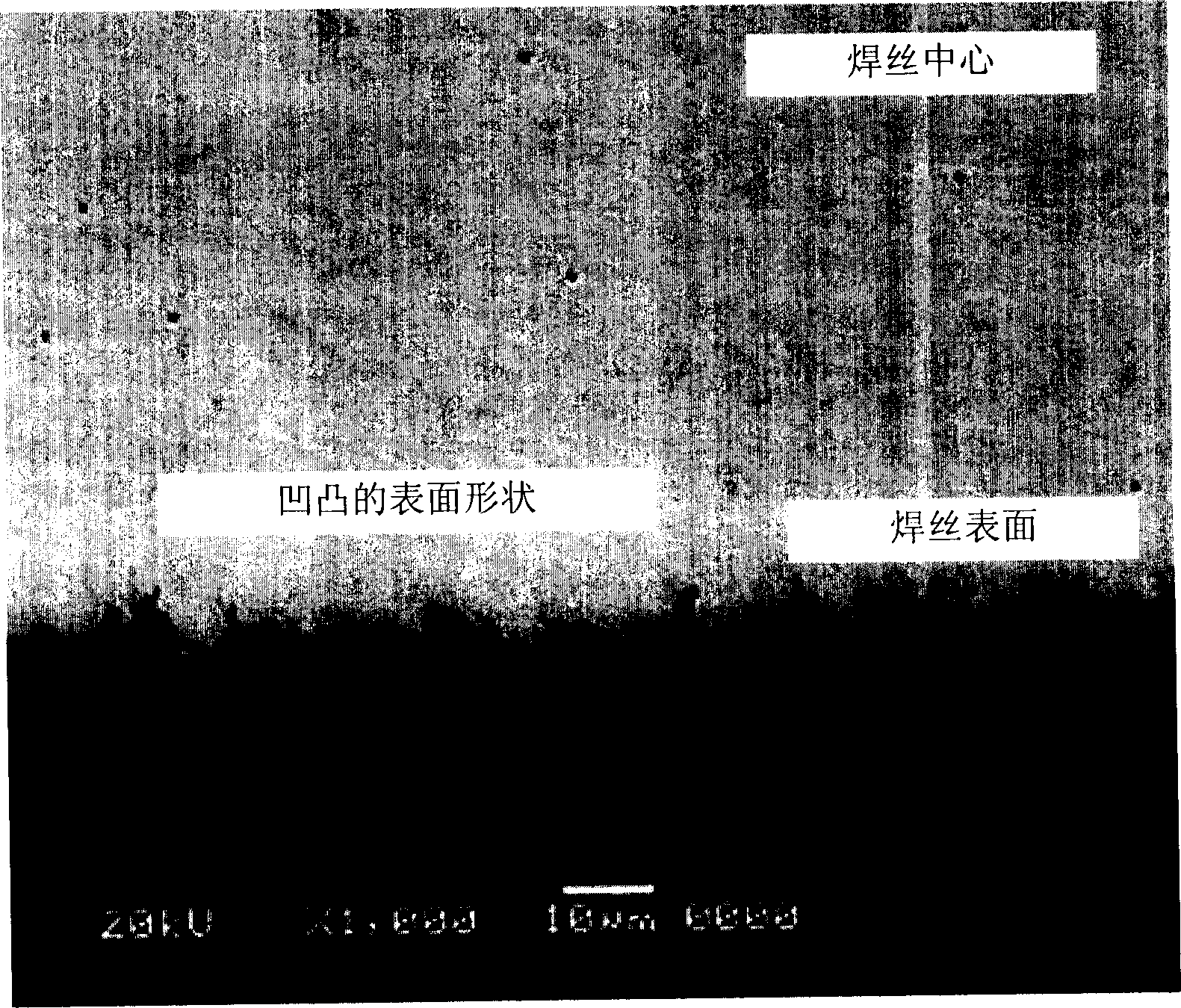

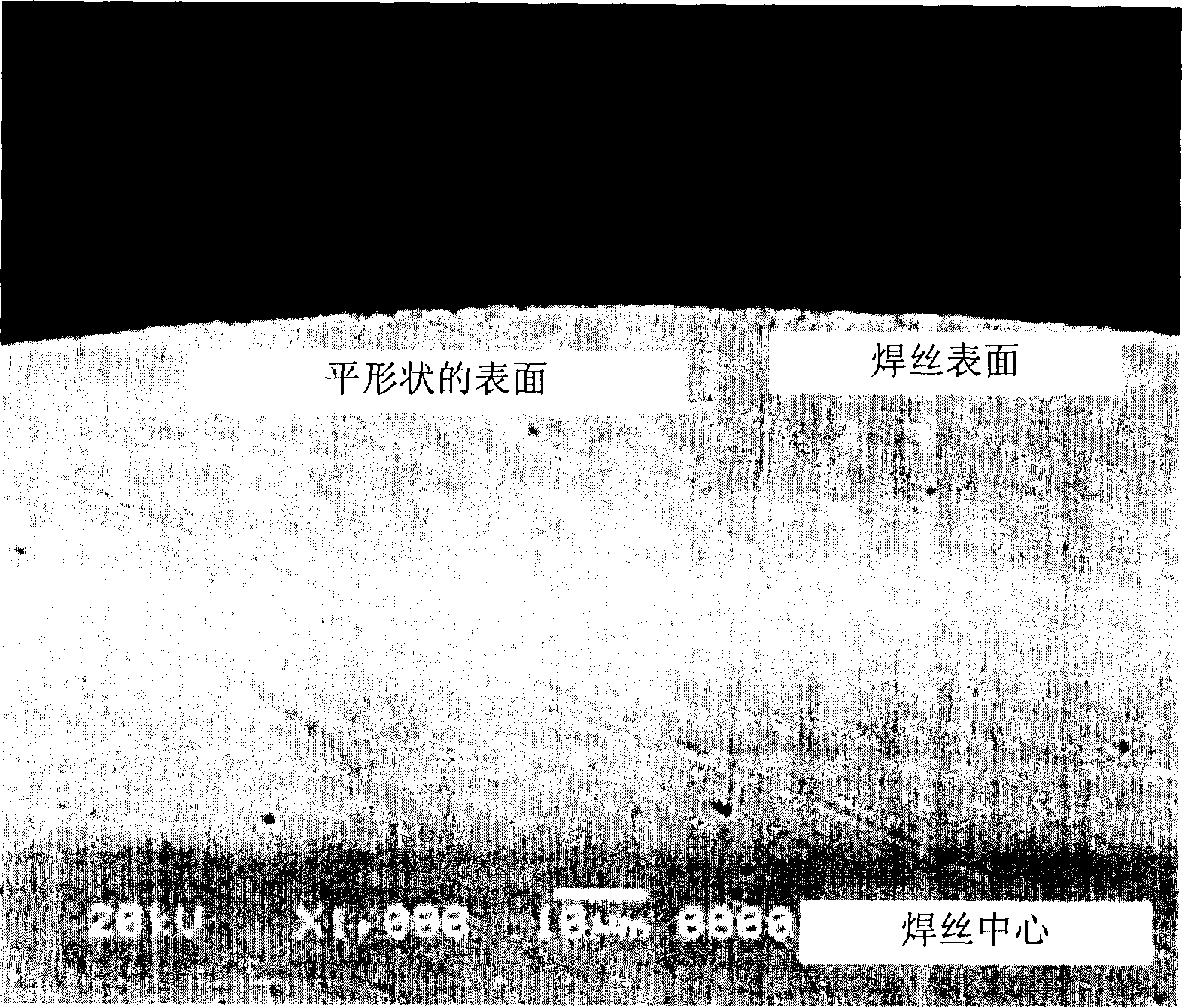

[0021] The present inventors conducted various experiments in order to impart special properties to the surface of the welding wire to replace the copper-plated layer on the surface of the welding wire. As a result, the present inventors found that the wire surface can be divided into three categories, namely, the plane formed only by the machined sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com