White-light luminous diode

A technology of light-emitting diodes and diodes, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of poor color saturation and display color temperature, low luminous efficiency, etc., and achieve the effect of good color saturation and display color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

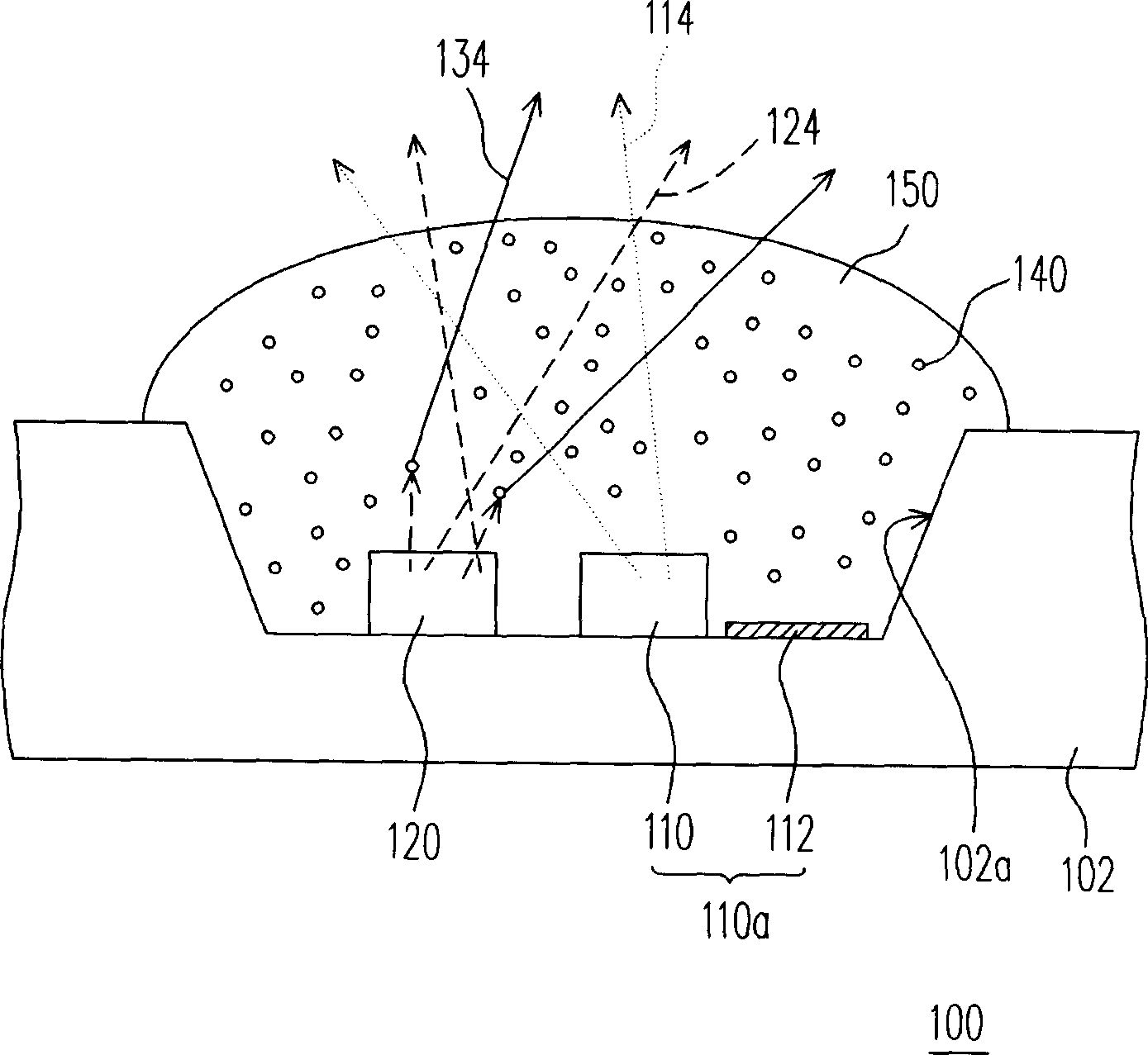

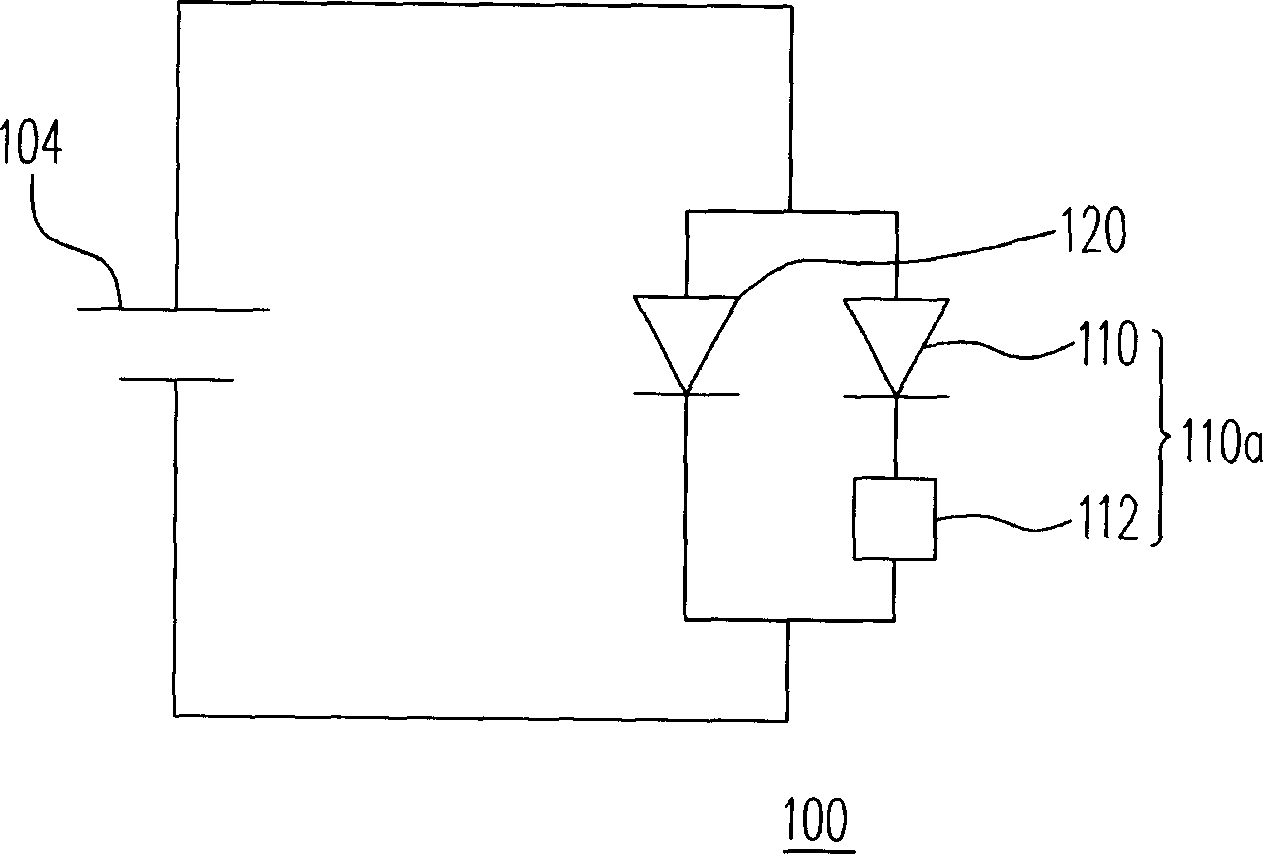

[0035] Please also refer to Figure 1A and 1B ,in Figure 1A It is a schematic cross-sectional view of a white light emitting diode according to a preferred embodiment of the present invention, and Figure 1B for Figure 1A The circuit diagram of white light emitting diode. In addition, in order to simplify the drawings to clearly express the features of the present invention, Figure 1A The cross-sectional schematic diagram does not show the relevant connecting wires or circuit of the substrate. Such as Figure 1A and 1B As shown, the white light emitting diode 100 includes a red light emitting diode chip 110, a blue light emitting diode chip 120 and a carrier 102, wherein the carrier 102 is, for example, a packaging substrate, and the red light emitting diode chip 110 and the blue light emitting diode chip 120 are, for example, disposed on In the cavity 102a on the surface of the carrier 102. In addition, the red light emitting diode chip 110 is connected in series with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com