Micro band slot array antenna

A microstrip slot and array antenna technology, which is applied in the direction of slot antennas, antennas, antenna arrays, etc., can solve the problems of large antenna thickness, low-profile advantages of microstrip antennas, and poor radiation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

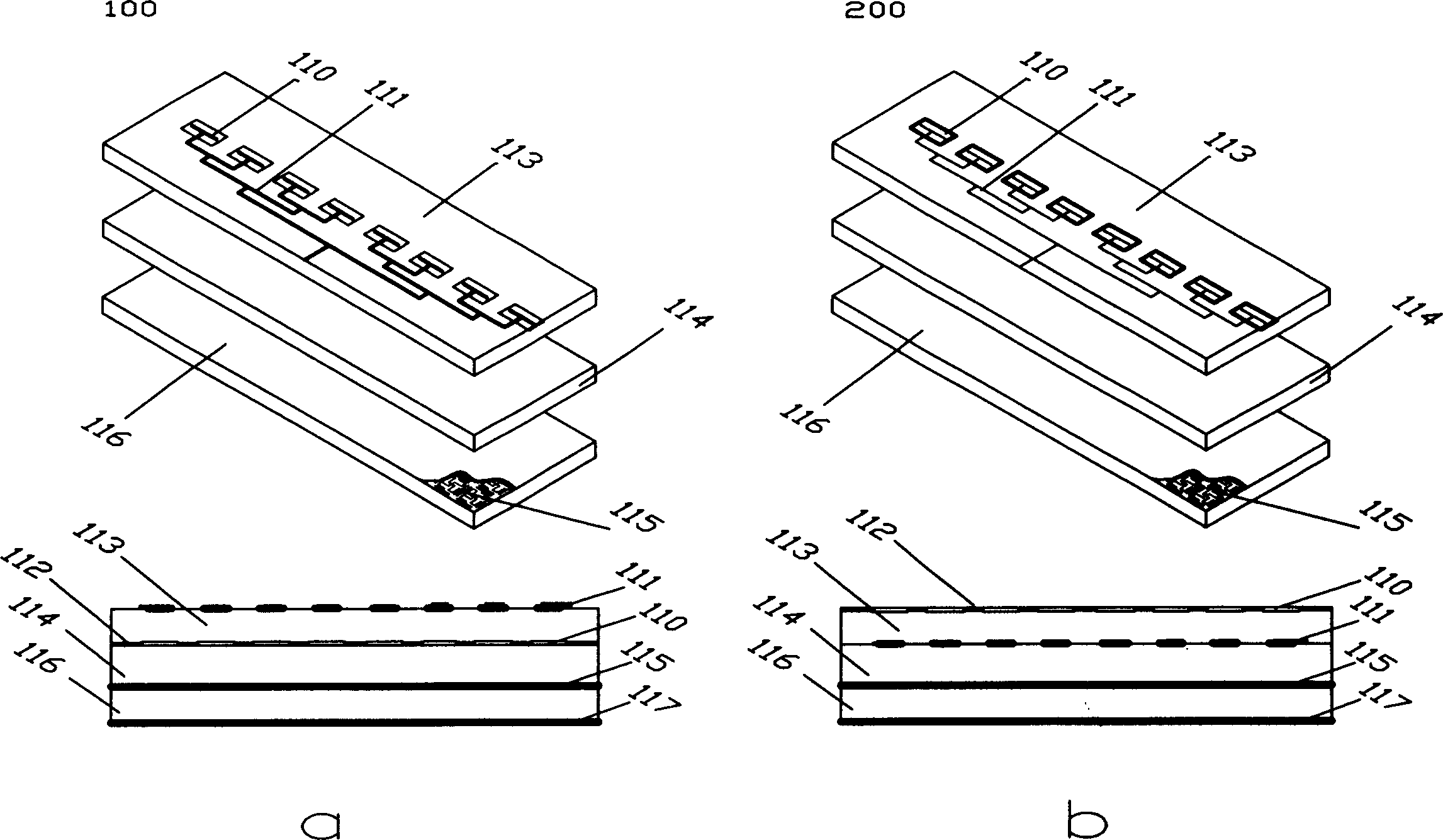

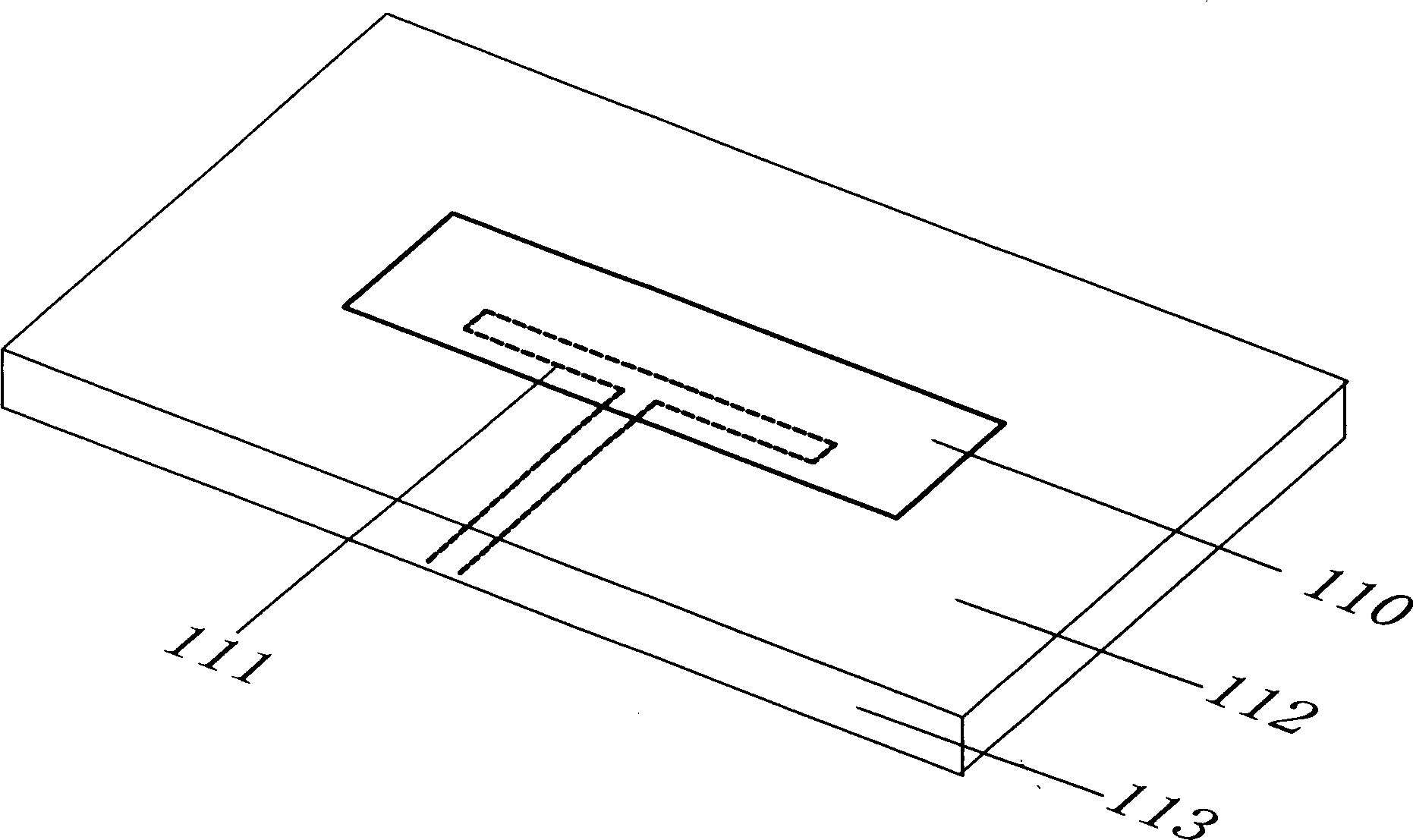

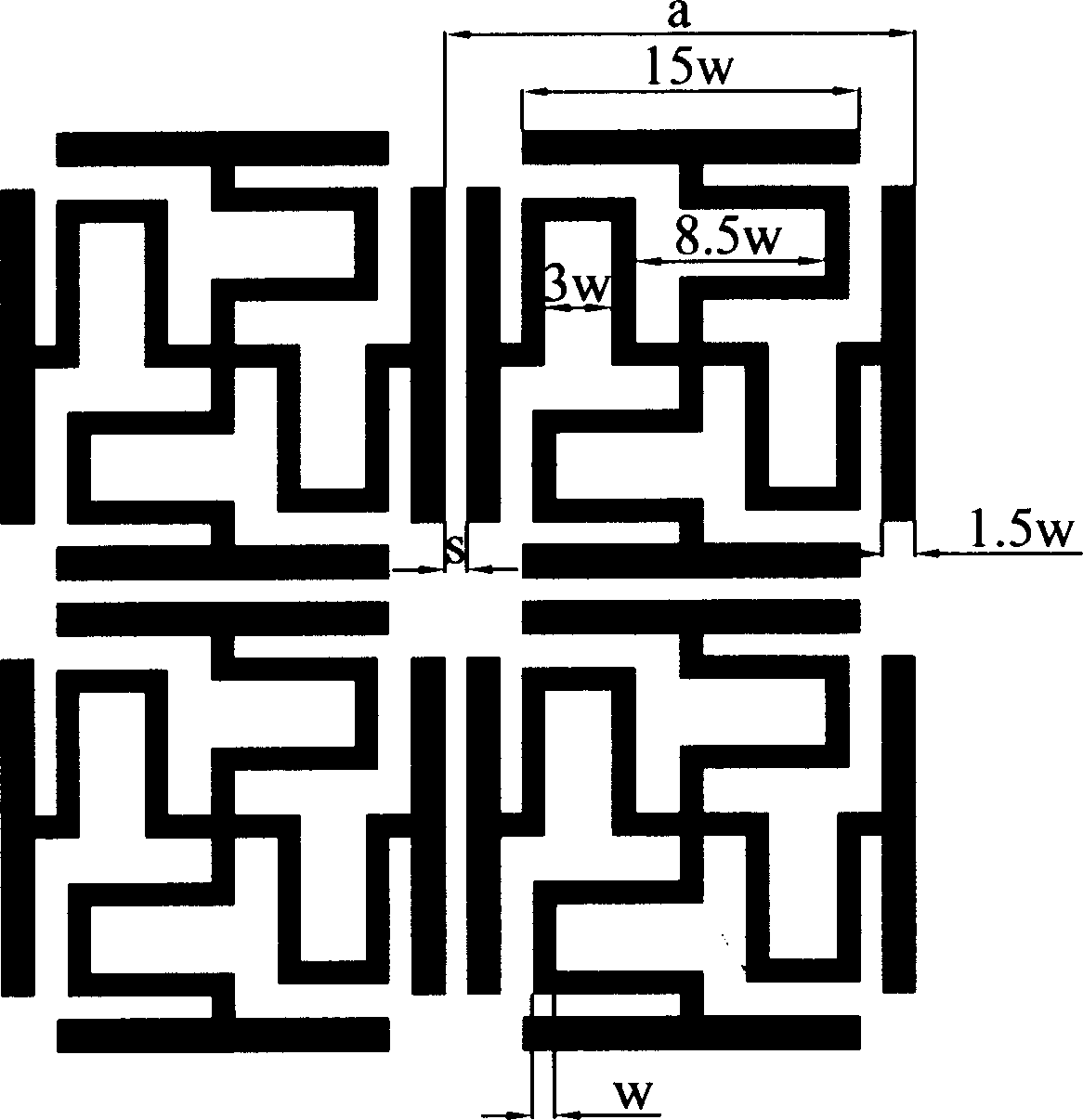

[0011] Example one, see figure 1 (a) This embodiment is a 1×8 matrix microstrip slot array antenna 100 with 8 slot antennas, the slot 110 is located on the lower surface of the dielectric plate 113, the periphery of the slot 110 is a metal ground 112, and the feed line 111 is located on the dielectric plate On the upper surface of 113, under the dielectric plate 113 is the isolation layer 114, and the bottom is the high-resistance magnetic permeable surface substrate 116. The high-resistance surface permeable pattern 115 is located on the upper surface of the high-resistance permeable surface substrate 116. The lower surface of is the metal base plate 117; the specific size parameters and material selection are calculated according to the applied frequency band according to the existing wireless communication theory. In this embodiment, the frequency application range is 3.4 GHz to 3.53 GHz, and the dielectric plate 113 is selected Microwave dielectric materials with a dielectric...

Embodiment 2

[0013] Example two, see figure 1 (b) This embodiment is a 1×8 matrix microstrip slot array antenna 200 with 8 slot antennas, the slot 110 is located on the upper surface of the dielectric plate 113, the periphery of the slot 110 is a metal ground 112, and the feed line 111 is located on the dielectric plate The bottom surface of 113, under the dielectric plate 113 is the isolation layer 114, the bottom is the high-resistance permeable surface substrate 116, the high-resistance surface permeable pattern 115 is located on the upper surface of the high-resistance permeable surface substrate 116, The lower surface of is the metal bottom plate 117; the specific size parameters and material selection are calculated according to the applied frequency band according to the existing wireless communication theory. In this embodiment, the frequency application range is 3.4 GHz to 3.53 GHz, and the dielectric plate 213 is selected Microwave dielectric materials with a dielectric constant of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com