Process for preparing nano-grade cadmium sufide hollow ball

A technology of cadmium sulfide and hollow spheres, applied in the direction of cadmium sulfide, can solve the problems of reducing the purity of nanoparticles, cumbersome experimental operation, etc., and achieve the effects of high yield, simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Dissolve 0.2Kg of PEG in 1L of deionized water to dissolve it. 0.15KgCd(NO 3 ) 2 4H 2 O and 0.12Kg Na 2 S·9H 2 O was dissolved in the above 0.5L PEG solution respectively to obtain solutions A and B. Control the temperature at 30-40°C, slowly add solution B to solution A dropwise, and the color of the solution changes from colorless to yellow. After the reaction, the reaction solution was centrifuged, the supernatant was discarded, the precipitate was repeatedly washed with water, centrifuged for 3 to 5 times, and dried in vacuum to obtain a CdS sample. This description can be so.

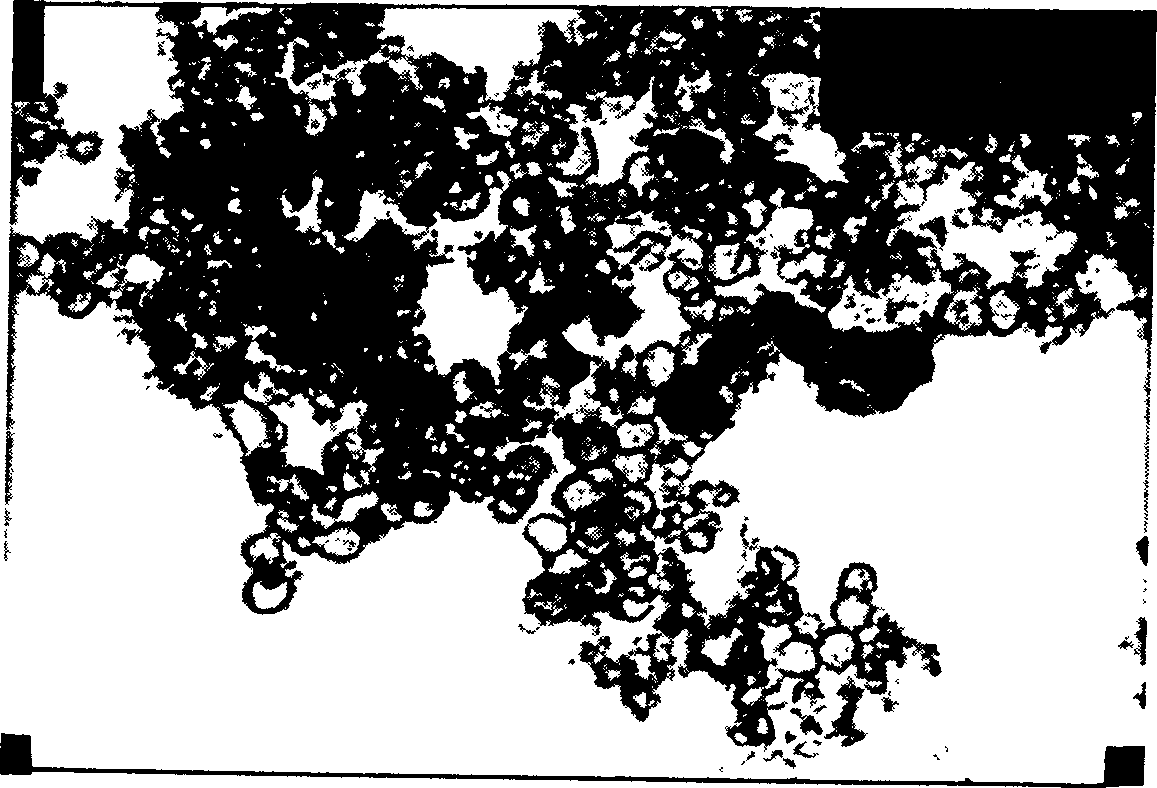

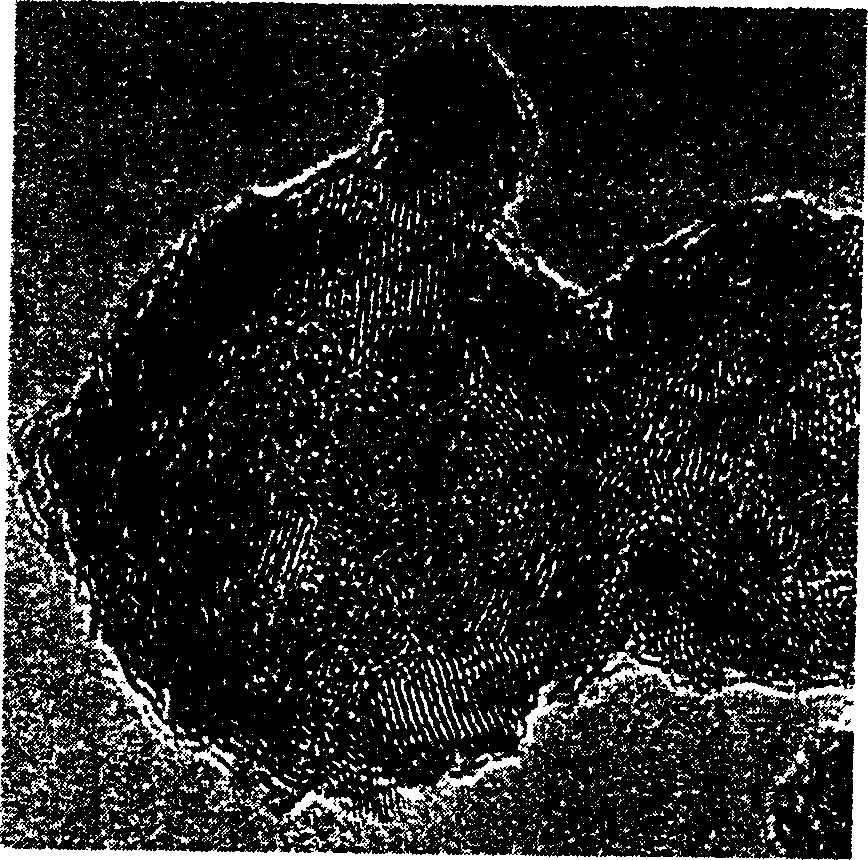

[0026] This example proves that: when the PEG feeding amount is 0.2Kg, the TEM image of the prepared CdS hollow sphere is as follows figure 1 shown. It can be seen from the figure that the diameters of CdS hollow spheres are distributed in the range of 10-30nm, and the average diameter is 20nm. Further observations with high-resolution transmission electron microscopy ...

Embodiment 2

[0027] Embodiment 2: substantially the same as embodiment 1, but Cd(NO 3 ) 2 4H 2 O consumption is 0.15Kg.

[0028] When the PEG feeding rate is 0.05Kg, the diameter distribution of the obtained CdS hollow spheres is 3-10 nm, and the average diameter is 5 nm.

Embodiment 3

[0029] Embodiment 3: substantially the same as embodiment 1, but Cd(NO 3 ) 2 4H 2 O consumption is 0.5Kg.

[0030] When the PEG feeding rate is 0.5Kg, the diameter distribution of the obtained CdS hollow spheres is 5-10 nm, and the average diameter is 7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com