Process for producing British standard 460 grade thread reinforcing steel by ordinary carbon steel

A technology of threaded steel bar and process method, which is applied in the direction of manufacturing tools, roll speed control, heat treatment equipment, etc., can solve the problems of large consumption of steel resources, increase the weight of buildings, and increase the amount of steel bars, so as to reduce the amount of steel and save steel resources. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

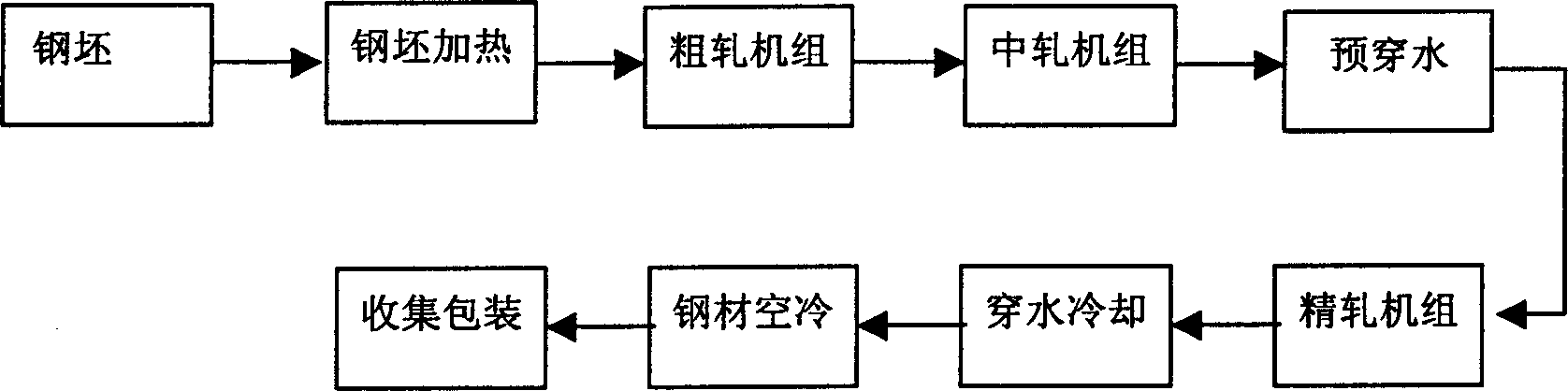

[0019] figure 1 Shown is the embodiment of the processing method of adopting common carbon steel to produce British standard 460 grade threaded steel bar of the present invention, comprises the following steps:

[0020] a. Use ordinary carbon steel, such as ordinary carbon steel Q235 grades C and D, the content of C element is 0.17-0.22%, and the content of Mn element is 0.35-0.8%. After the steel billet is heated and released from the furnace, the starting rolling temperature is maintained at 900-980 ° C. After the rough and intermediate rolling units (rough rolling 7, intermediate rolling 6) under high pressure, the maximum elongation coefficient μ of the rolling mill is 1.449, and then the steel is cooled by pre-piercing water cooling ; According to various rolling specifications, the number of sections of the pre-piercing section is 1-3, the water pressure is 0.5-0.8Mpa (see Table 1), and the temperature of the steel after pre-piercing is 850-950°C;

[0021] b. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com