Methane distribution type sensing method and equipment based on optical fiber Bragg grating

An optical fiber Bragg and sensing method technology, applied in the field of optical fiber sensing, can solve the problems of difficult measurement, poor integration, hidden safety hazards, etc., and achieve the effects of strong anti-electromagnetic interference ability, simple structure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

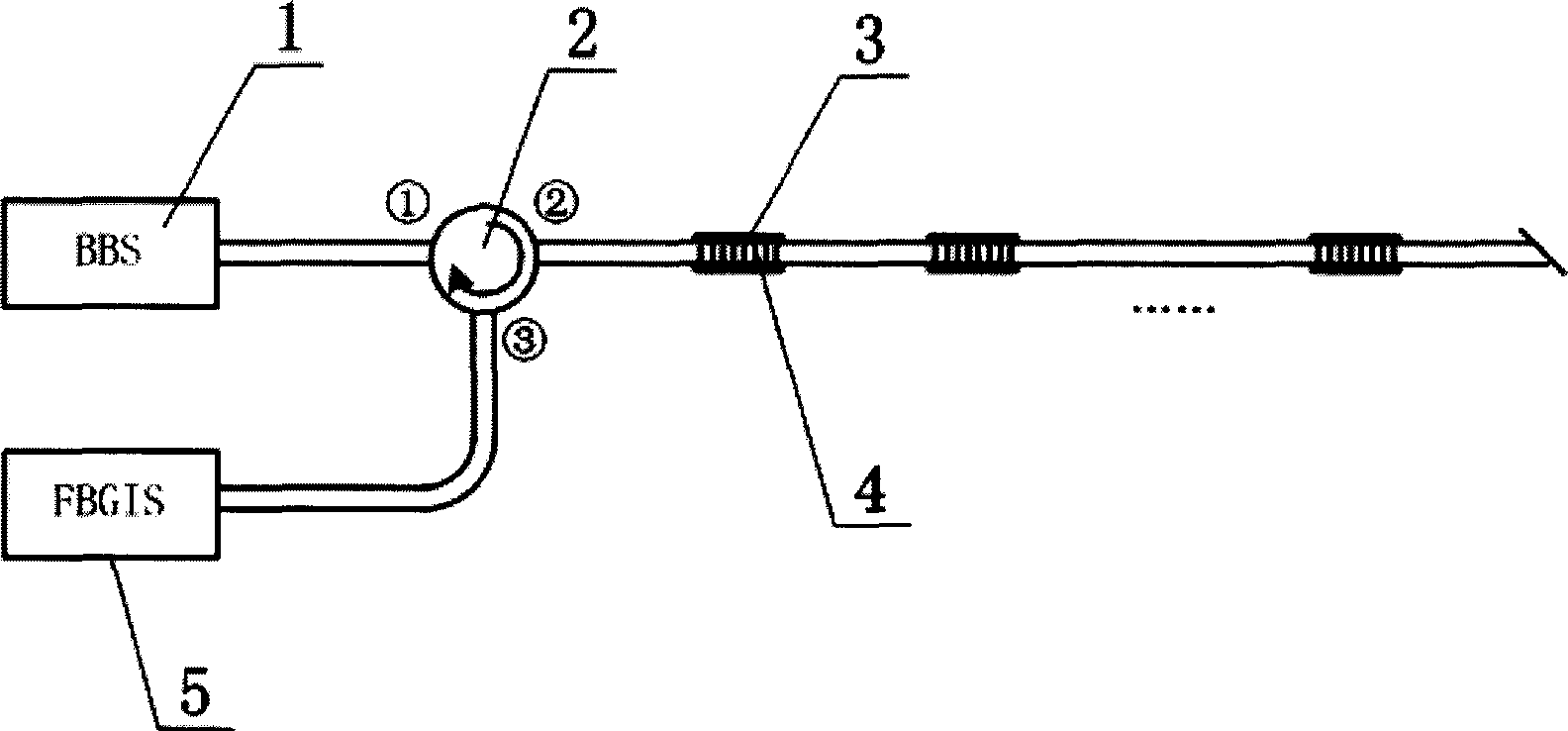

[0018] Such as figure 1 , select a group of fiber Bragg gratings 4 whose reflection peak wavelength positions are separated by 3 nanometers to be connected in series; use vacuum coating technology to coat a layer of 3 micron platinum film 3 on the surface of each fiber Bragg grating 4 as a catalyst. Under the action of the catalyst, methane in the gas to be measured reacts with oxygen in the air to release heat, which increases the temperature near the platinum film 3 and causes the position of the reflection peak of the fiber Bragg grating 4 to shift. Broadband light source 1 covering all fiber Bragg grating reflection peak wavelengths is connected to port ① of circulator 2 through optical fibers, and port ② of circulator 2 is connected to a group of fiber Bragg gratings 4 coated with platinum film 3 through optical fibers. The ③ port of the device 2 is connected with the fiber Bragg grating wavelength division multiplexing demodulation system 5 through an optical fiber.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com