Undersea four-core oil-filled cable

A technology of oil-filled cables and cable cores, applied in submarine cables, insulated cables, power cables, etc., can solve the problems of high cable laying costs, high difficulty coefficient, and waste of space, and achieve strong anti-electromagnetic interference and shielding effects Good, the effect of small core wire outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

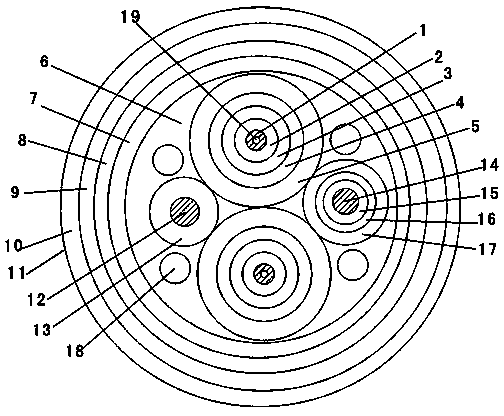

[0019] Such as figure 1 As shown, a four-core oil-filled cable for seabed according to the present invention includes two insulated wire cores, an optical fiber communication cable core, and a data wire core stranded; There is a filling layer 6, and the inner sheath 7, the shielding layer 8, the water blocking layer 9, the armor layer 10 and the outer sheath 11 are arranged in sequence outside the cable core; Outer conductor insulation layer 2, conductor shielding layer 3, oil-filled insulating paper 4 and sheath 5; the conductor 1 is a hollow structure, and the conductor 1 is provided with an oil channel 19; A plurality of reinforcing cores 18 are arranged in the gaps of the cable cores. The optical fiber communication cable core is composed of an optical fiber 14, a loose tube 15, an aramid yarn 16 and a sheath tube 17 which are sequentially extruded outside the optical fiber.

[0020] The data insulation core is formed by wrapping the data insulation layer 13 around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com