Disk coating system

A technology for processing systems and disks, applied in coatings, metal material coating processes, instruments, etc., can solve problems such as extending the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

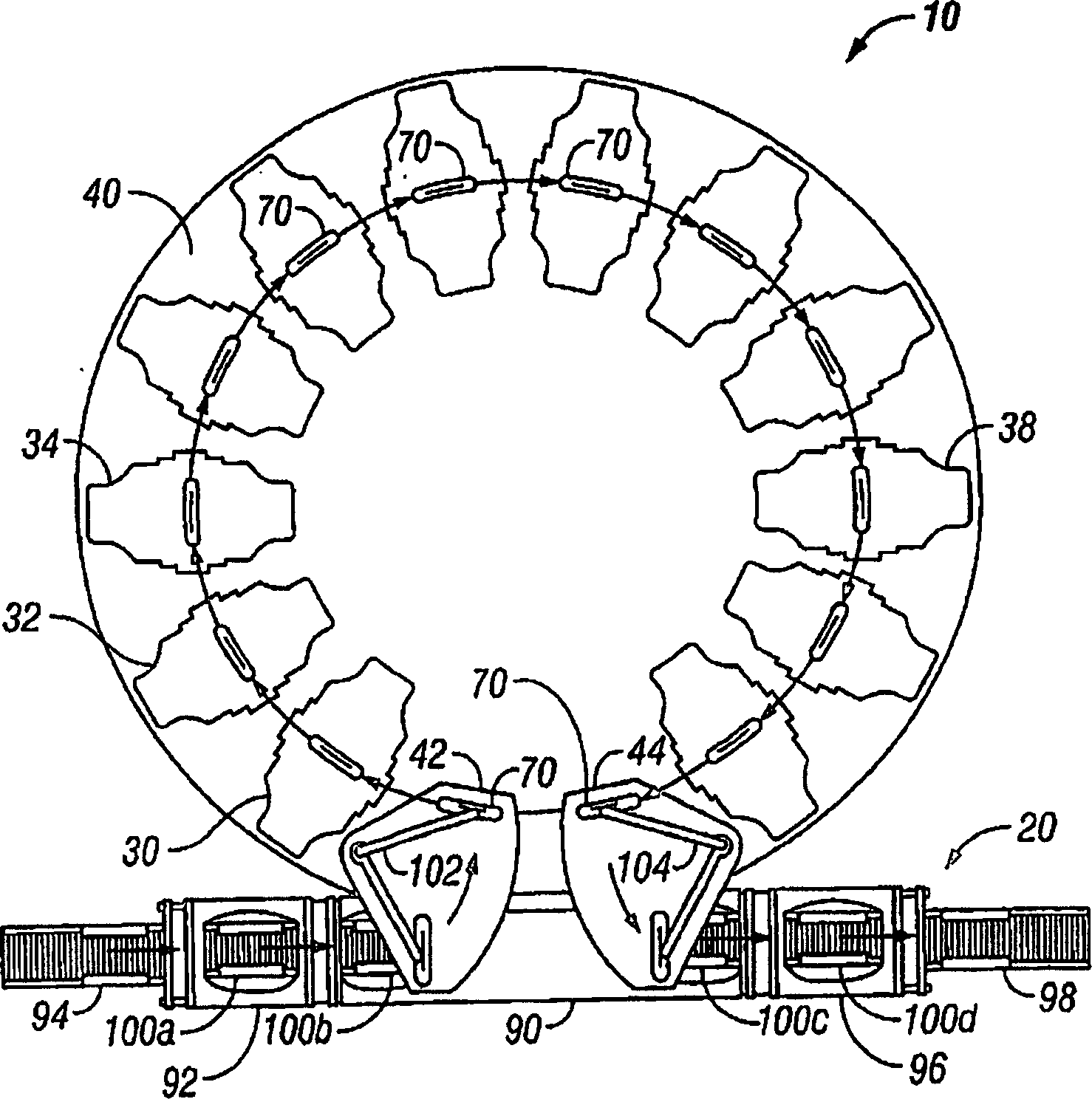

[0022] Figure 1 shows a prior art substrate processing system in which like elements have been given like reference numerals. As shown in FIG. 1 , the system includes a processing unit 10 and a substrate processing system 20 . The processing unit 10 includes a plurality of processing stations 30 , 32 , 34 etc. installed on a main vacuum chamber 40 . The processing stations 30 , 32 , 34 etc. are arranged in a circular arrangement with respect to the circular central main vacuum chamber 40 . The processing unit 10 also includes a loading station 42 for loading the system with substrates for processing and an unloading station 44 for unloading the substrates from the system after processing. The substrate is generally a substrate used in the manufacture of magnetic hard disks or used in the manufacture of magneto-optical discs. The substrate and the final disk contain a central opening. The substrate processing system may also include a vacuum pump, power supply and controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com