Integral membrane biological reaction device for water treatment

A water treatment device and membrane bioreaction technology, applied in the field of environmental engineering, can solve the problems of high turbidity, not enough to meet the reuse standard, and difficulty in ensuring the quality of effluent water, etc., and achieve the effect of reducing the degree of membrane pollution and long equipment operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

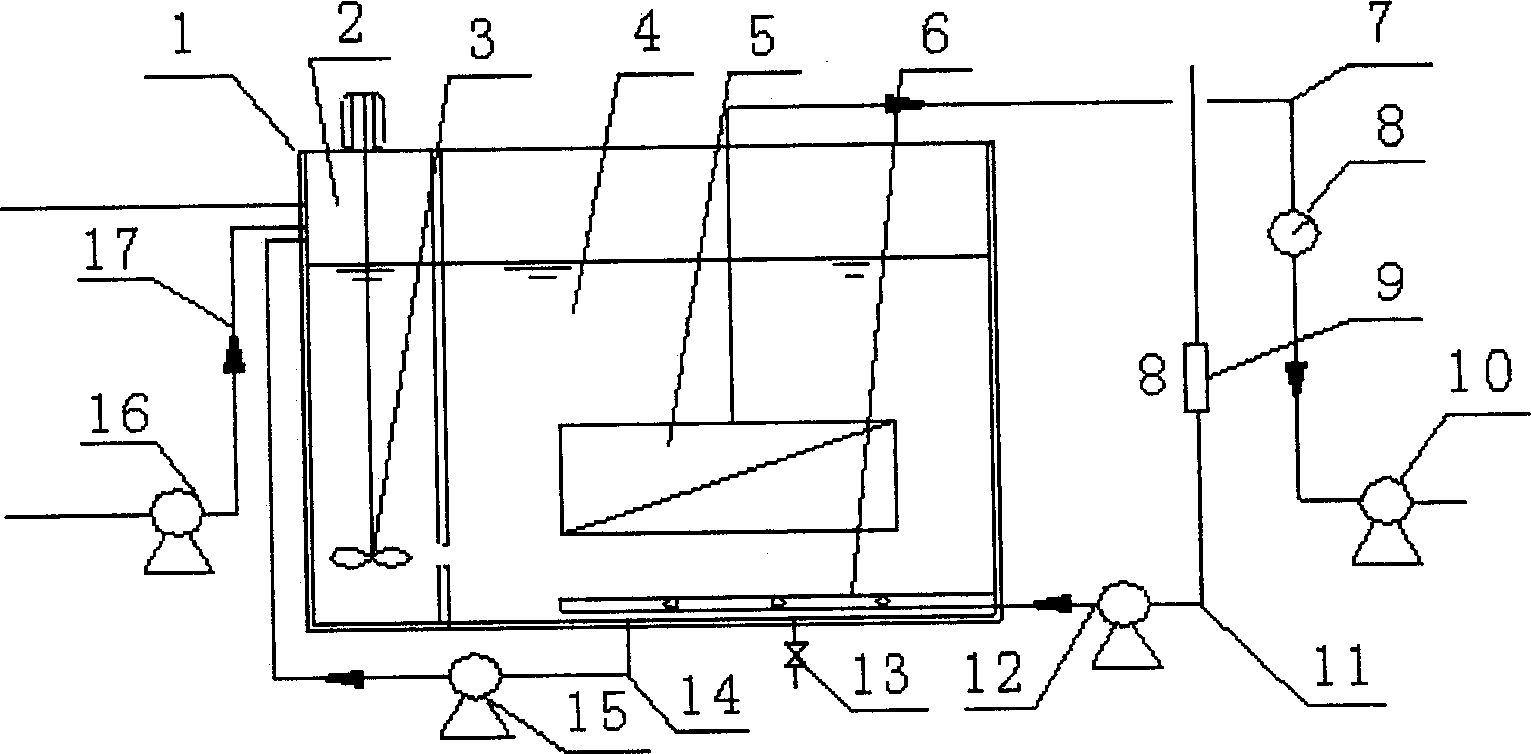

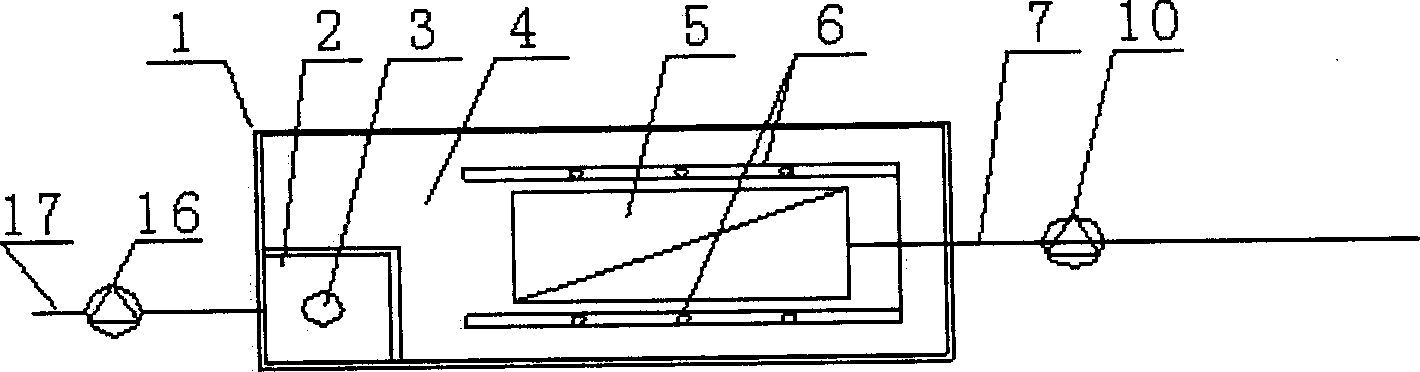

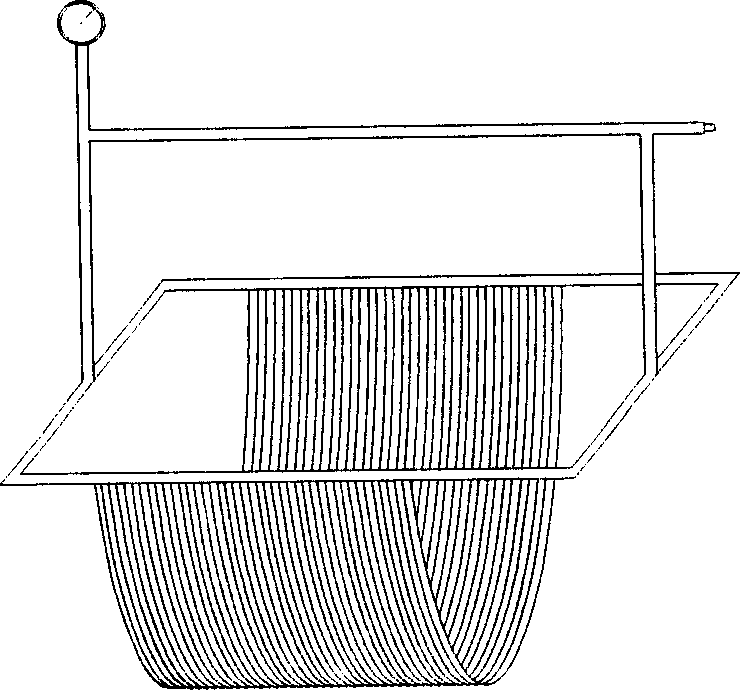

[0021] A preferred embodiment of the present invention is: see figure 1 , figure 2 and image 3 , the integrated membrane bioreaction water treatment device includes a reaction tank 1 divided into anoxic zone 2 and aerobic zone 4, agitator 3 set in anoxic zone 2, and exposure tank placed in aerobic zone 4 The trachea 6 and the air pump 12 connected to the air inlet pipe 11, the water inlet pump 16 on the water inlet pipe 17 of the anoxic zone 2, the water outlet pump 10 on the water outlet pipe 7 of the aerobic zone 4, and from the aerobic zone 4 to the anoxic zone A circulating activated sludge water treatment device composed of a return pump 15 on the sludge return pipe 14 in area 2, a membrane module 5 is arranged in the aerobic area 4, and the water outlet pipe 7 is connected from the water outlet of the membrane module 5 It is connected to the inlet of the water outlet pump 10 described above. There is also a vacuum pressure gauge 8 on the above-mentioned outlet pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com