High power electromagnetic oven output power control device

A high-power induction cooker and output power technology, applied in the direction of induction heating control, induction heating devices, household stoves/stoves, etc., can solve the problems of output power fluctuation, IGBT heating, and zero-voltage shutdown can not be guaranteed, so as to achieve low switching loss, The effect of reducing fluctuations and solving heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

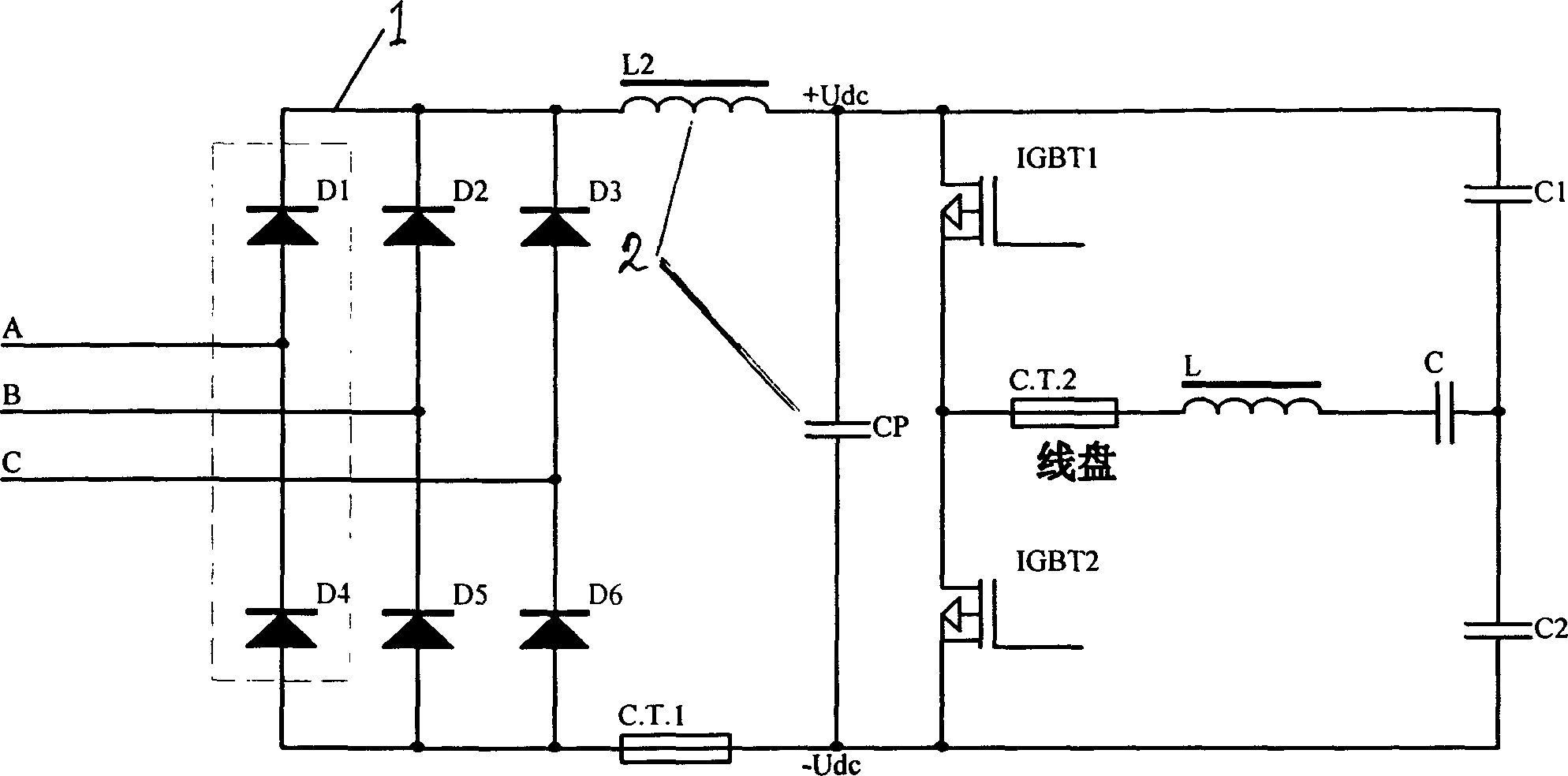

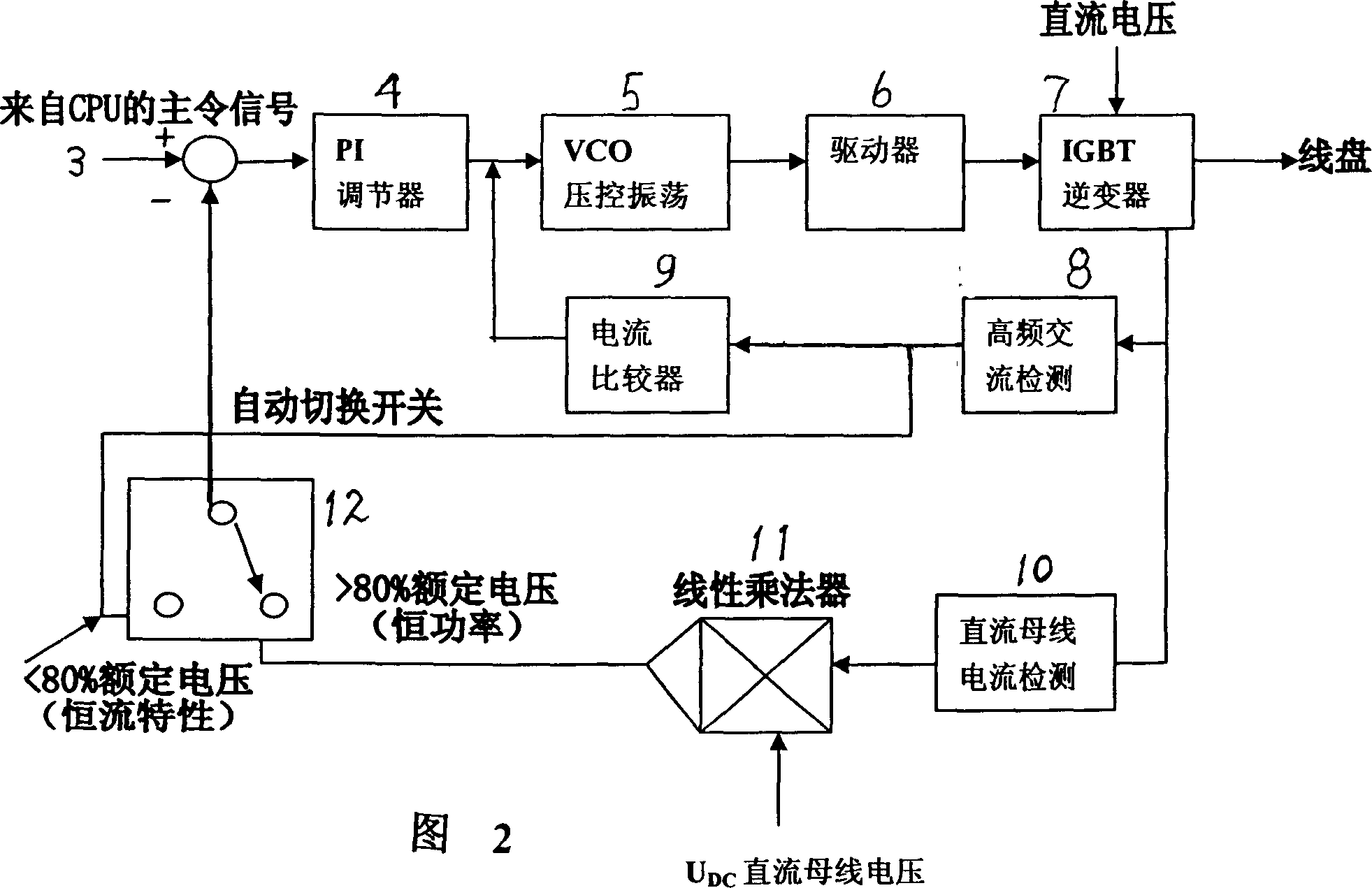

[0014] Please refer to the attached figure 1 As shown, the main circuit is input by the rectifier circuit 1 and the filter circuit 2, connected to the power switch tubes IGBT1, IGBT2, the power switch tubes IGBT1, IGBT2 are connected to the series circuits LC1, LC2, and the capacitor C is also optional, where L is the furnace The resonant frequency of the coil inductance, the series resonant circuit formed by the capacitors C1, C2 and the inductance L is slightly lower than the driving frequency of the power switch tube. A high-frequency AC detector CT2 is connected in series in the series resonant circuit as a sampling signal of the current closed-loop control circuit, and a DC bus current detector CT1 is connected in series in the DC bus circuit as a power closed-loop control sampling signal.

[0015] The power switch tubes IGBT1 and IGBT2 are driven by a driving circuit 6 , the working frequency of the driving circuit 6 is controlled by the voltage-controlled oscillator 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com