Dimethyl formamide effluent gases recovering and processing method for dry method synthetic leather

A technology for recovery of dimethylformamide and waste gas, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems of biochemical oxygen consumption, chemical oxygen consumption and increased nitrogen content, water quality deterioration, DMF The market price is expensive and other issues, to achieve the effect of protecting human health, improving water quality, and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

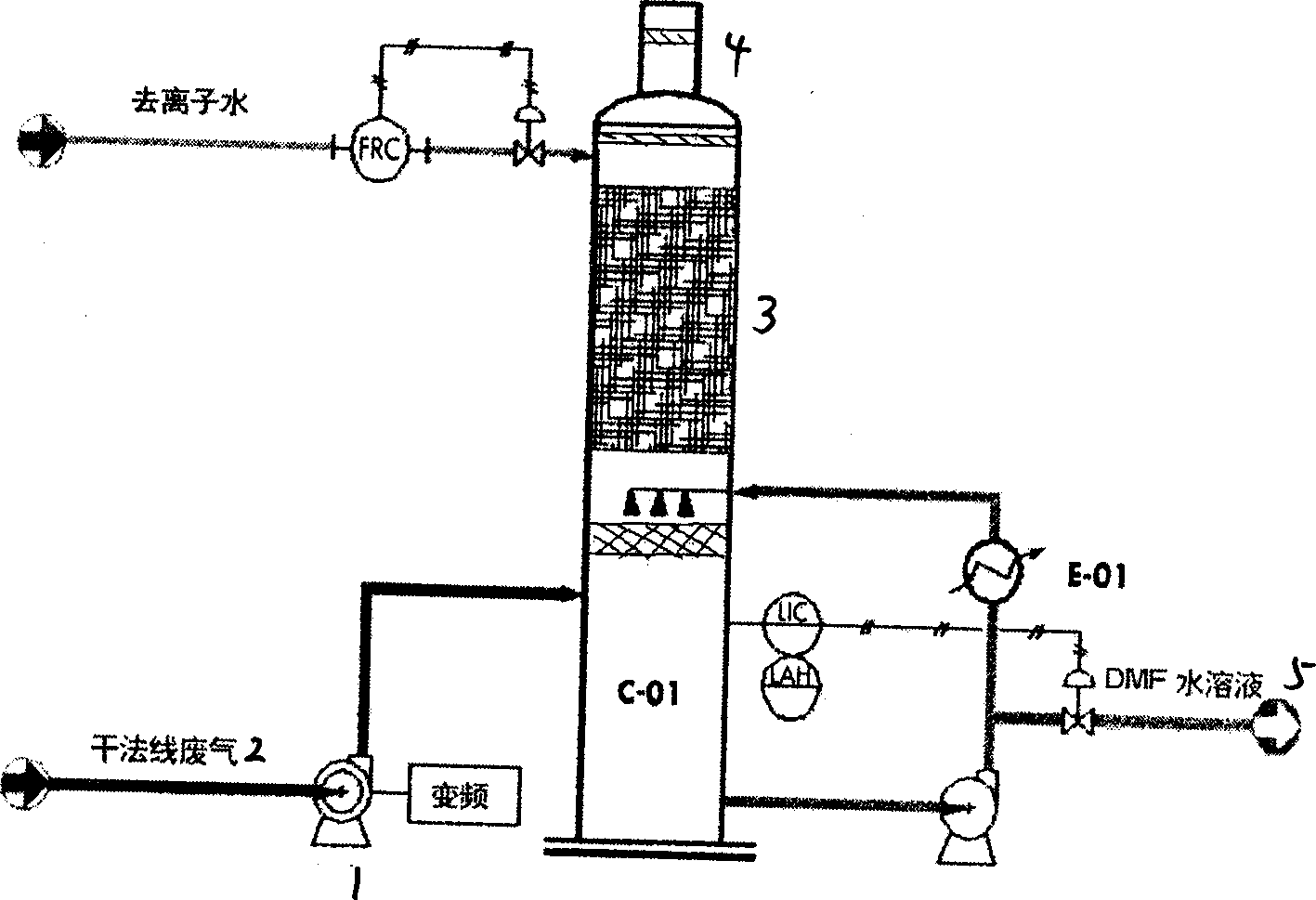

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention adopts domestically produced new wire mesh fillers with superior overall performance such as large specific surface area, high plate height, and small pressure drop to replace imported ones, and its separation effect is better; The solid outer spiral nozzle has better atomization degree and distribution uniformity, which ensures a larger contact area and more effective contact time for gas-liquid contact; improves the exhaust gas collection structure; designs and manufactures high-efficiency liquid distributors; designs and manufactures The corresponding packed absorption tower.

[0012] According to the requirements of the dry production process, set the performance parameters of the fan, select a high-efficiency frequency conversion and energy-saving fan 1 of a first-class listed company, and send the waste gas 2 produced by dimethylformamide int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com