Method for preparing lithium enriched lithium ion phosphate powder

A technology of lithium iron phosphate and powder, which is applied in the field of preparation of electrochemical power source materials, achieves obvious effects and advantages, wide application prospects, and the effect of improving the matrix basic capacity and cycle electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The specific method of the preparation method of the lithium-rich type lithium iron phosphate powder is as follows:

[0020] Lithium salt, ferrous salt, phosphate and substitutes are fed at one time according to the molar ratio of element Li:Fe:P:B=(1+2x):1:(1-x):x, and then deionized water, At least one of industrial alcohol and absolute ethanol is used as the mixing medium, and the mixing and ball milling time is 6-12 hours, dried at 40-70°C, heated at 400-550°C under an inert atmosphere or a reducing atmosphere, and kept for 5-10 hours. Carry out pre-calcination within 1 hour; ball mill the pre-calcined material for 6-12 hours for the second time, dry it at 40-70°C, and then heat it at 550-850°C for the second calcination under an inert or reducing atmosphere to obtain lithium-rich lithium iron phosphate Li 1+2x Fe(P 1-x B x )O 4 Powder.

[0021] The boron substitution source is at least one of boric acid, trimethyl borate and boron oxide.

[0022] The lithium ...

Embodiment 1

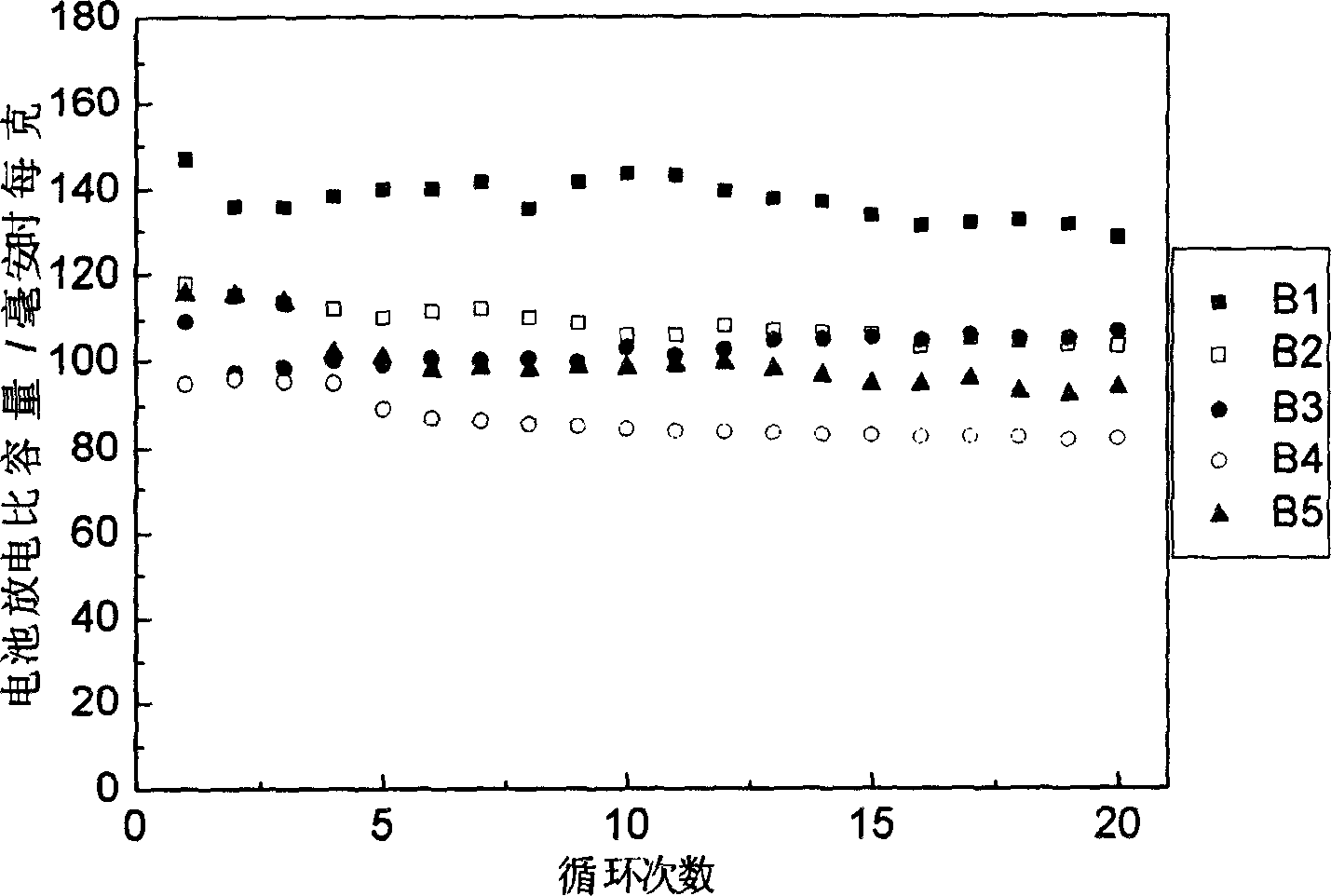

[0029] 0.05025 moles of lithium carbonate Li 2 CO 3 , 0.1 mole ferrous oxalate Fe(C 2 o 4 )·2H 2 O and 0.09975 moles of ammonium dihydrogen phosphate NH 4 h 2 PO 4 and 0.00025 moles of boric acid H 3 BO 4 Mix, add to a polyester tank, add 55ml of absolute alcohol, seal and mix on a planetary ball mill for 10 hours, discharge and dry under a nitrogen atmosphere of 0.3 liters / minute, and raise the temperature to 400°C, keep it at this temperature for 8 hours, cool down to room temperature with the furnace, and get the pre-fired material, then use industrial alcohol as the medium for ball milling for 6 hours, and dry the material under 0.3 liters / min of nitrogen atmosphere at 4°C / min. The heating rate of 1 minute is raised to 700 ° C, and the temperature is kept at this temperature for 8 hours, and then the temperature is lowered to room temperature with the furnace, and the positive electrode material Li 1.005 Fe(P 0.9975 B 0.0025 )O 4 , recorded as B1.

[0030] The...

Embodiment 2

[0032] 0.1015 mol lithium hydroxide LiOH·H 2 O, 0.1 mole of ferrous acetate Fe(CH 3 COO) 2 2H 2 O and 0.09925 moles of diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 and 0.00075 moles of trimethyl borate (CH 3 O) 3 B is mixed, put into the polyester tank, add 80ml of industrial alcohol, seal and mix on the planetary ball mill for 6 hours. 430°C, keep warm at this temperature for 7.5 hours, cool down to room temperature with the furnace, take out the pre-fired material and add it to the polyester tank, add an appropriate amount of deionized water, seal it and ball mill it for 10 hours, and dry it at 0.3 liters / minute Under a nitrogen-hydrogen mixed atmosphere (nitrogen:hydrogen = 9:1, volume ratio), the temperature was raised to 720°C at a rate of 4°C / min, kept at this temperature for 7 hours, and cooled to room temperature with the furnace to obtain the positive electrode material Li 1.015 Fe(P 0.9925 B 0.0075 )O 4 , recorded as B2.

[0033] Weigh 1.125gLi 1.015 Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com