Removal of minim iodine ion from brine liquor which is material of caustic soda produced by ion membrane method

A technology of iodide ion and brine, applied in the direction of alkali metal compounds, alkali metal hydroxides, alkali metal oxides/hydroxides, etc., can solve the problems of high operating cost, large amount of regeneration liquid, difficult to recycle, etc., and achieve operating cost Low, long operating cycle, easy to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

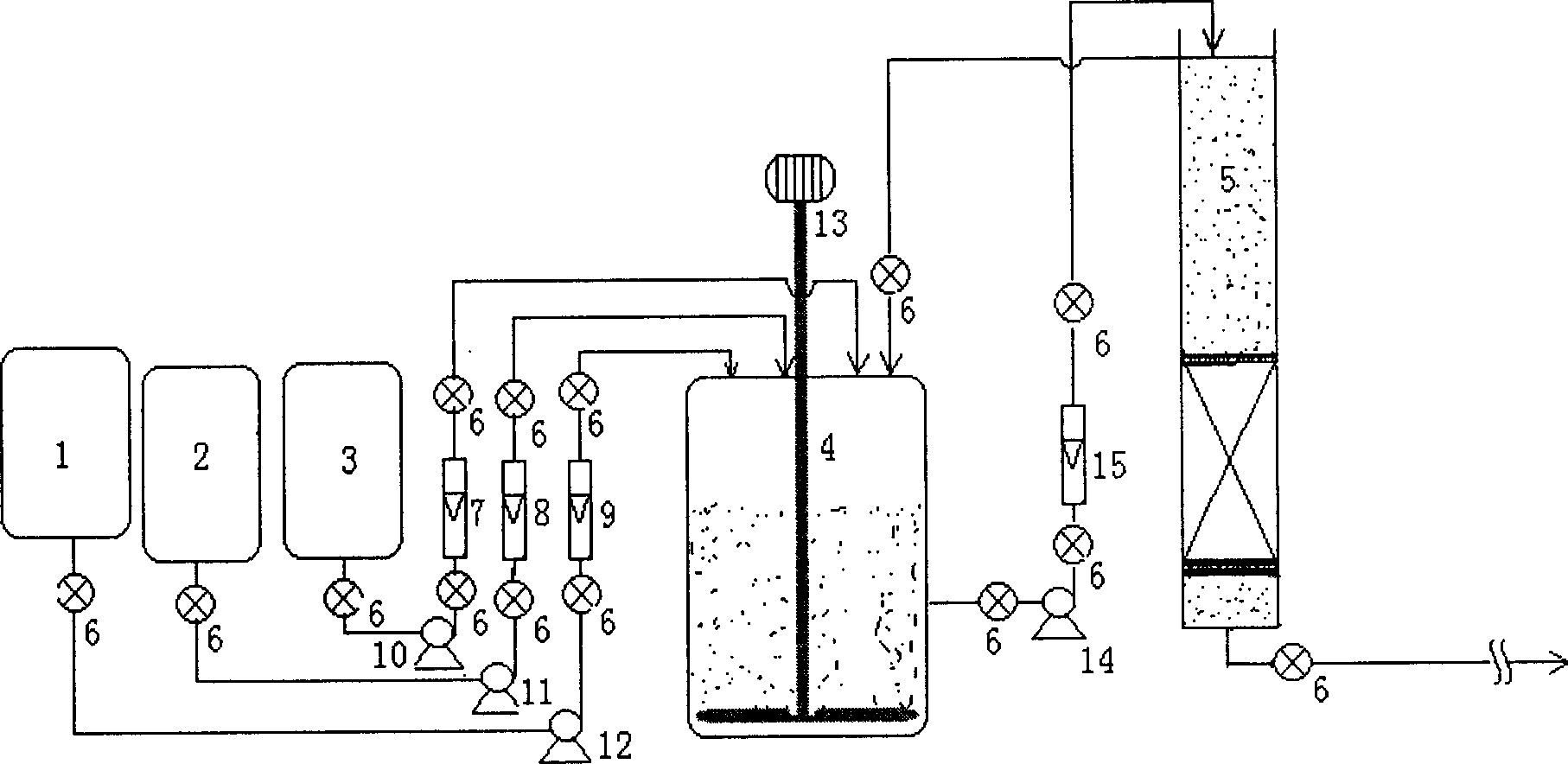

Method used

Image

Examples

Embodiment 1

[0014] The original brine of Taishan Salt Chemical Industry Co., Ltd. of Xinwen Mining Group was used, and the iodine content of the original brine was 0.21mg / L. Add acid to adjust the pH=2, add 400ml of oxidizing agent, the oxidation time is 120min, and the iodine content of the treated brine is 0.035mg / L.

Embodiment 2

[0016] The original brine of Taishan Salt Chemical Industry Co., Ltd. of Xinwen Mining Group was used, and the iodine content of the original brine was 0.21mg / L. Add acid to adjust pH=4, add oxidant 400ml, oxidation time is 120min, the iodine content of brine after treatment is 0.034mg / L.

Embodiment 3

[0018] The original brine of Taishan Salt Chemical Industry Co., Ltd. of Xinwen Mining Group was used, and the iodine content of the original brine was 0.17mg / L. Add acid to adjust pH=6, add 400ml of oxidizing agent, the oxidation time is 60min, and the iodine content of the treated brine is 0.038mg / L.

[0019] (4) Embodiment 4

[0020] The original brine of Taishan Salt Chemical Industry Co., Ltd. of Xinwen Mining Group was used, and the iodine content of the original brine was 0.21mg / L. Add acid to adjust pH=6, add 5ml of oxidizing agent, the oxidation time is 60min, and the iodine content of the treated brine is 0.039mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com