Method for producing iron oxide black using desilicified mud cake

A technology of iron oxide black and desiliconized mud cake, which is applied in the direction of iron oxide/iron hydroxide, ferric oxide, etc., can solve the problems of high raw material cost, high raw material cost, single product variety, etc., and achieve low equipment requirements , Excellent performance, less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

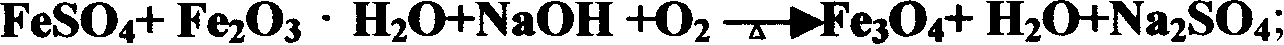

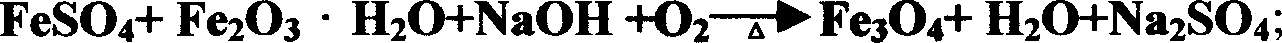

Method used

Image

Examples

Embodiment

[0021] Preparation of ferrous solution and ferric citrine seeds.

[0022] Desiliconized mud cake treatment: Take 1000kg of desiliconized mud cake with a water content of 30%, and add it to the mud cake beating kettle, add water while adding water to disperse, the stirring speed of the beating kettle is 45 rpm, and the capacity of the beating kettle reaches 50% At this time, steam was introduced to ensure that the liquid temperature reached 80°C, and stirred for 2 hours to fully disperse the mud cake into a slurry. Then the slurry is pumped into the filter press for hot water rinsing, and then put into another beating kettle for beating.

[0023] Oxidation pulping: pump the treated two kettles of mud cake slurry into a 50m 3 In the iron yellow reaction kettle, pour 9m 3 The iron citrine seed slurry, add a proper amount of water, add a sufficient amount of thin iron material in time, control the reaction temperature, ensure the final holding temperature of 85 ℃, and make 40m a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com