Aqueous aromatic urethane elastomer and its preparation method

A polyurethane elastomer and aromatic technology, applied in the field of water-based aromatic polyurethane elastomer and its manufacturing, can solve the problems of easy cracking, user allergies, high price, etc., achieve good antistatic properties, easy penetration or detachment , the effect of saving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

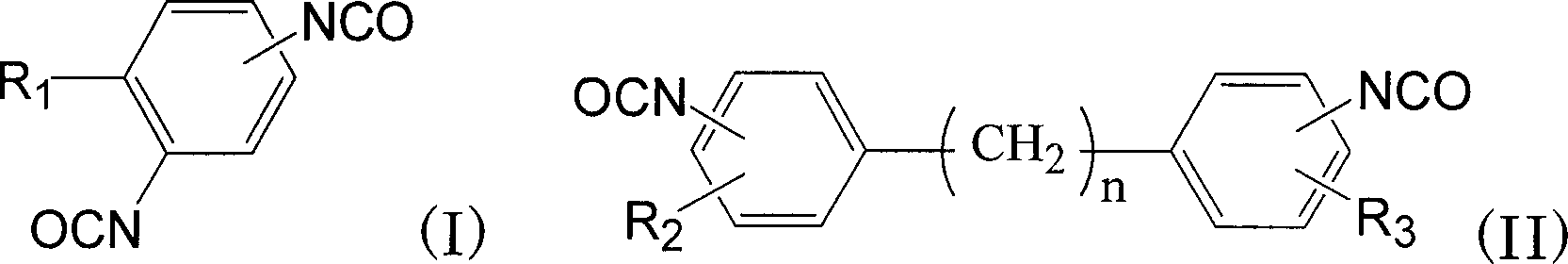

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (making of PU-A elastomer)

[0036] First, preparation of an aqueous aromatic polyurethane dispersion is carried out. 10.36 grams of dimethylol butionic acid (Dimethylol butionic acid, DMBA) and 17.39 grams of acetone were placed in a reaction tank protected by nitrogen and stirred evenly. When the above-mentioned raw materials were in a homogeneous phase, 40.28 grams were mixed in a mixing ratio of 80:20 2,4- and 2,6-cresyl diisocyanate (Toluene diisocyanate, TDI) was added to the reaction tank, and reacted at 60 degrees Celsius for 1.5 hours, after that, 119.49 grams of polytetramethylene glycol ( Polytetramethylene Glycol, PTMEG) (Mn = 2,000) and 29.87 grams of polypropylene glycol (Polypropylene glycol, PPG) (Mn = 2,000), continue to react at 60 degrees Celsius for 4 hours, and then reduce the temperature of the reaction tank to 50 degrees Celsius And add 7.07 grams of triethylamine (Triethylamine, TEA) and carry out neutralization reaction 20 minutes,...

Embodiment 2

[0038] Embodiment 2 (making of PU-B elastomer)

[0039] First, preparation of an aqueous aromatic polyurethane dispersion is carried out. 10.36 grams of dimethylol butionic acid (Dimethylol butionic acid, DMBA) and 17.39 grams of N-methyl pyrrolidone (N-methyl pyrrolidone, NMP) were placed in a reaction tank with nitrogen protection and stirred evenly, and the above When the raw materials are in a homogeneous phase, add 38.05 grams of 2,4- and 2,6-toluenediisocyanate (TDI) with a mixing ratio of 80:20 into the reaction tank, and react at 60 degrees Celsius for 1.5 hours , after that, add 121.27 grams of polytetramethylene glycol (Polytetramethylene Glycol, PTMEG) (Mn=2,000) and 30.32 grams of polypropylene glycol (Polypropyleneglycol, PPG) (Mn=2,000), continue to react at 60 degrees Celsius for 4 hours, then , the temperature of the reaction tank was lowered to 50 degrees Celsius and 7.07 grams of triethylamine (Triethylamine, TEA) was added for neutralization reaction for 20...

Embodiment 3

[0041] Embodiment 3 (making of PU-C elastomer)

[0042] First, preparation of an aqueous aromatic polyurethane dispersion is carried out. 93.24 grams of dimethylol butionic acid (Dimethylol butionic acid, DMBA) and 156.52 grams of N-methyl pyrrolidone (N-methyl pyrrolidone, NMP) were placed in a reaction tank with nitrogen protection and stirred evenly, and the above When the raw material is in a homogeneous phase, add 362.51 grams of 2,4- and 2,6-toluenediisocyanate (TDI) with a mixing ratio of 80:20 into the reaction tank, and react at 60 degrees Celsius for 1.5 hours , after that, add 1034.04 grams of polytetramethylene glycol (Polytetramethylene Glycol, PTMEG) (Mn=2,000) and 310.21 grams of polypropylene glycol (Polypropyleneglycol, PPG) (Mn=2,000), continue to react at 60 degrees Celsius for 4 hours, then , the temperature of the reaction tank was lowered to 50 degrees Celsius and 63.63 grams of triethylamine (Triethylamine, TEA) was added for neutralization reaction for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com