Screw pile forming device and forming method

A technology for threaded piles and pile formation, which is applied in drilling equipment and methods, sheet pile walls, earthwork drilling, etc., can solve the problems of many pile formation processes, easy collapse of hole walls, and inability to construct piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

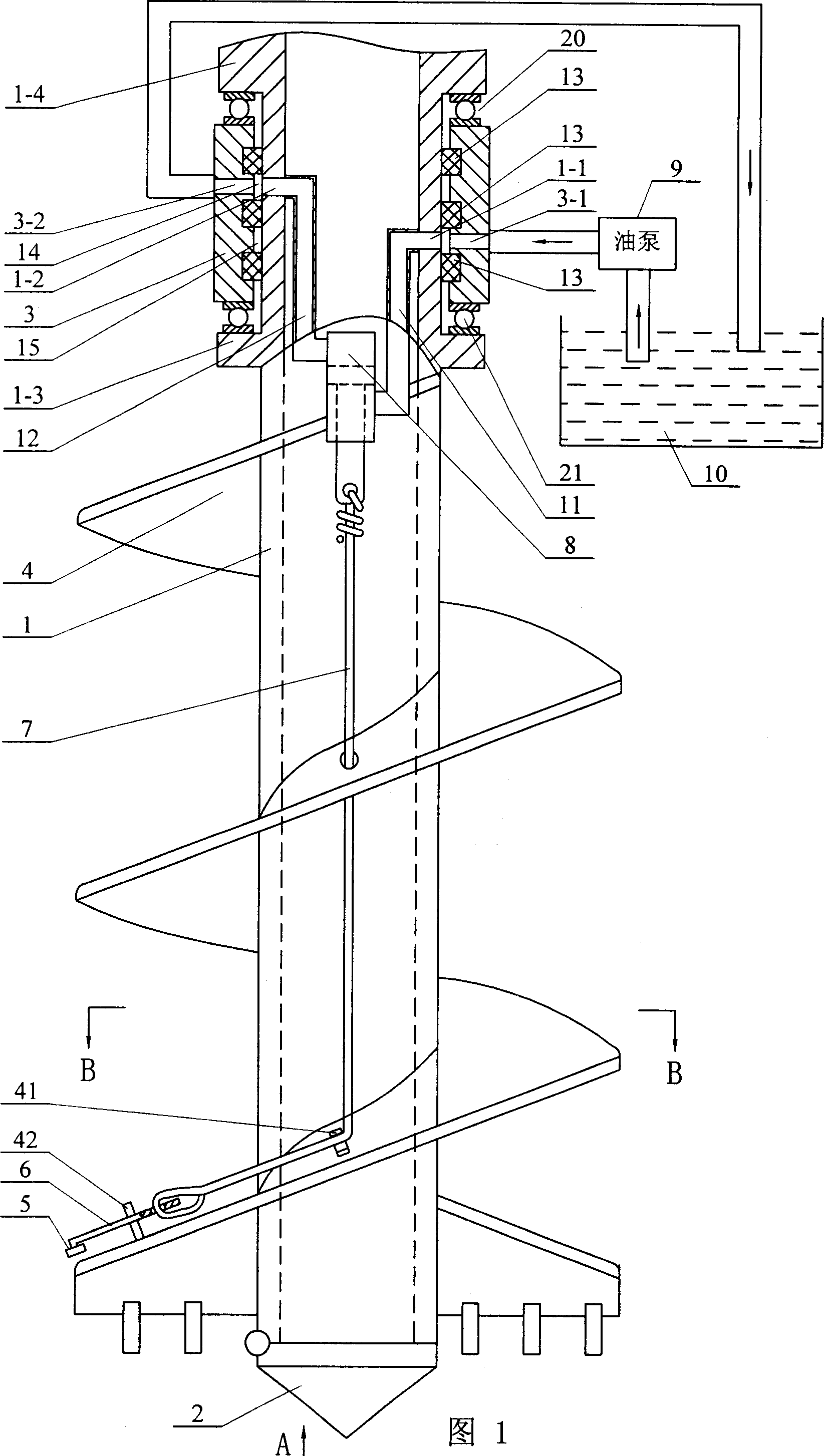

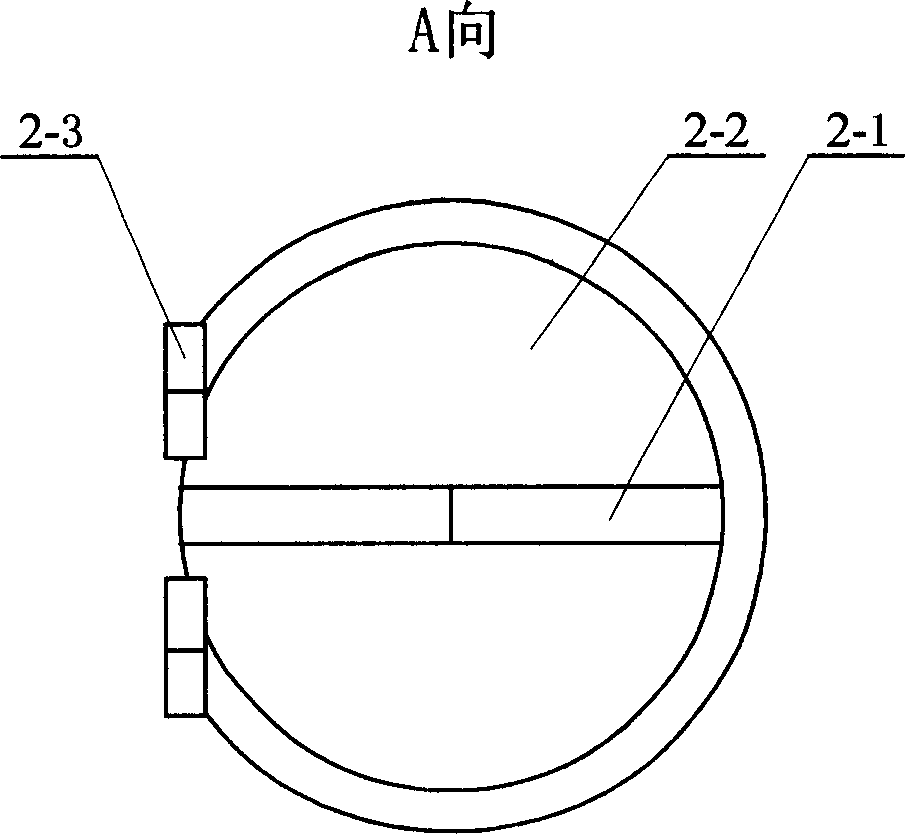

[0006] Specific embodiment one: below in conjunction with Fig. 1 and figure 2 , Figure 4 This embodiment will be described. This embodiment consists of a drill pipe 1, a drill bit 2, a jacket 3, a blade 4, a rolling wheel 5, a swing rod 6, a pulling rope 7, an oil cylinder 8, an oil pump 9, an oil tank 10, an oil inlet pipe 11, an oil return pipe 12, and a guide device 41 and three sealing rings 13, the blade 4 surrounds the outer surface of the hollow drill pipe 1, the drill bit 2 is hinged on the lower end of the drill pipe 1 and closes the lower end of the drill pipe 1, and the jacket 3 is set on the upper part of the drill pipe 1 and sleeved On the outer surface of the drill pipe 1, three sealing rings 13 are sequentially arranged between the inner surface of the outer casing 3 and the outer surface of the drill pipe 1 from top to bottom and form a first ring respectively between the two sealing rings 13. 14 and the second annulus 15, the oil outlet end of the oil pump ...

specific Embodiment approach 2

[0007] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between this embodiment and Embodiment 1 is: it also includes No. 1 bearing 20 and No. 2 bearing 21, the upper end of the outer cover 3 pushes against the lower end of the upper shoulder 1-4 of the drill pipe 1 through the No. 1 bearing 20, and the outer cover 3 The lower end of the drill rod 1 is pressed on the upper end of the lower shoulder 1-3 of the drill rod 1 by No. 2 bearing 21. In this way, the up and down displacement of the drill rod 1 will not cause the axial movement of the jacket 3 . Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

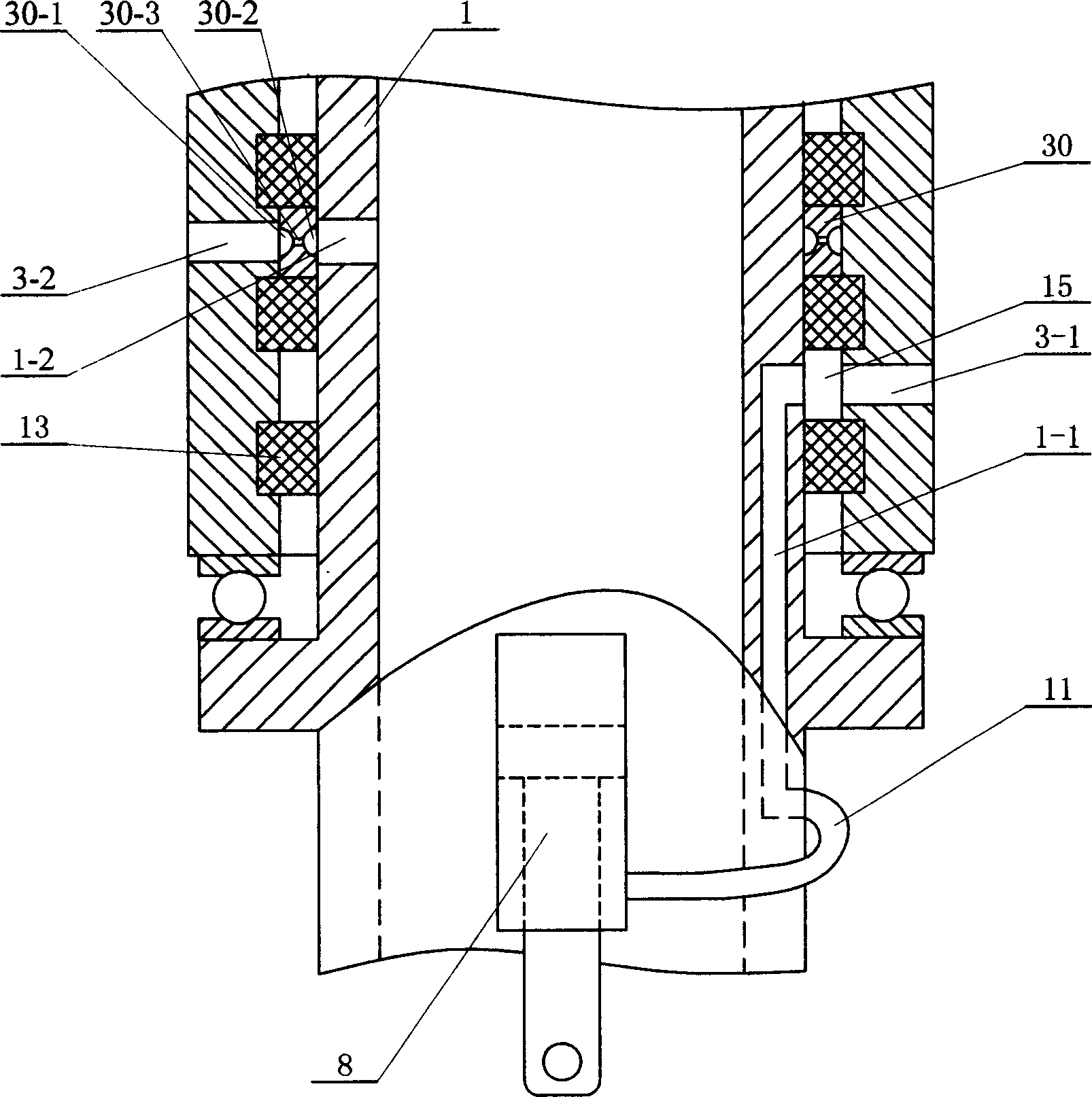

[0008] Specific embodiment three: below in conjunction with Fig. 1 and image 3 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is: it also includes a flower cover 30, which is arranged in the first annular space 14, and an outer ring groove 30-1 is opened on the outer circular surface of the flower cover 30, and the flower cover 30 There is an inner ring groove 30-2 on the inner hole surface of 30, and the outer ring groove 30-1 and the inner ring groove 30-2 are connected through the hole 30-3, and the outer ring groove 30-1 is connected with the second through hole 3 -2 is connected, and the inner ring groove 30-2 is connected with the second through hole 1-2. Such setting enables the sealing ring 13 to be axially positioned to ensure the smooth flow of the oil passage. Similarly, a flower cover 30 can also be arranged in the second annular space 15 . Other components and connections are the same as those in Embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com