Ionized gas sensor microarray structure based on micro-electronic fabrication technology

A technology of microarray structure and processing technology, applied in the field of devices in the field of microelectronics technology, can solve the problem of no device array structure, etc., and achieve the effects of enhancing signal strength, increasing detection precision and accuracy, and low work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

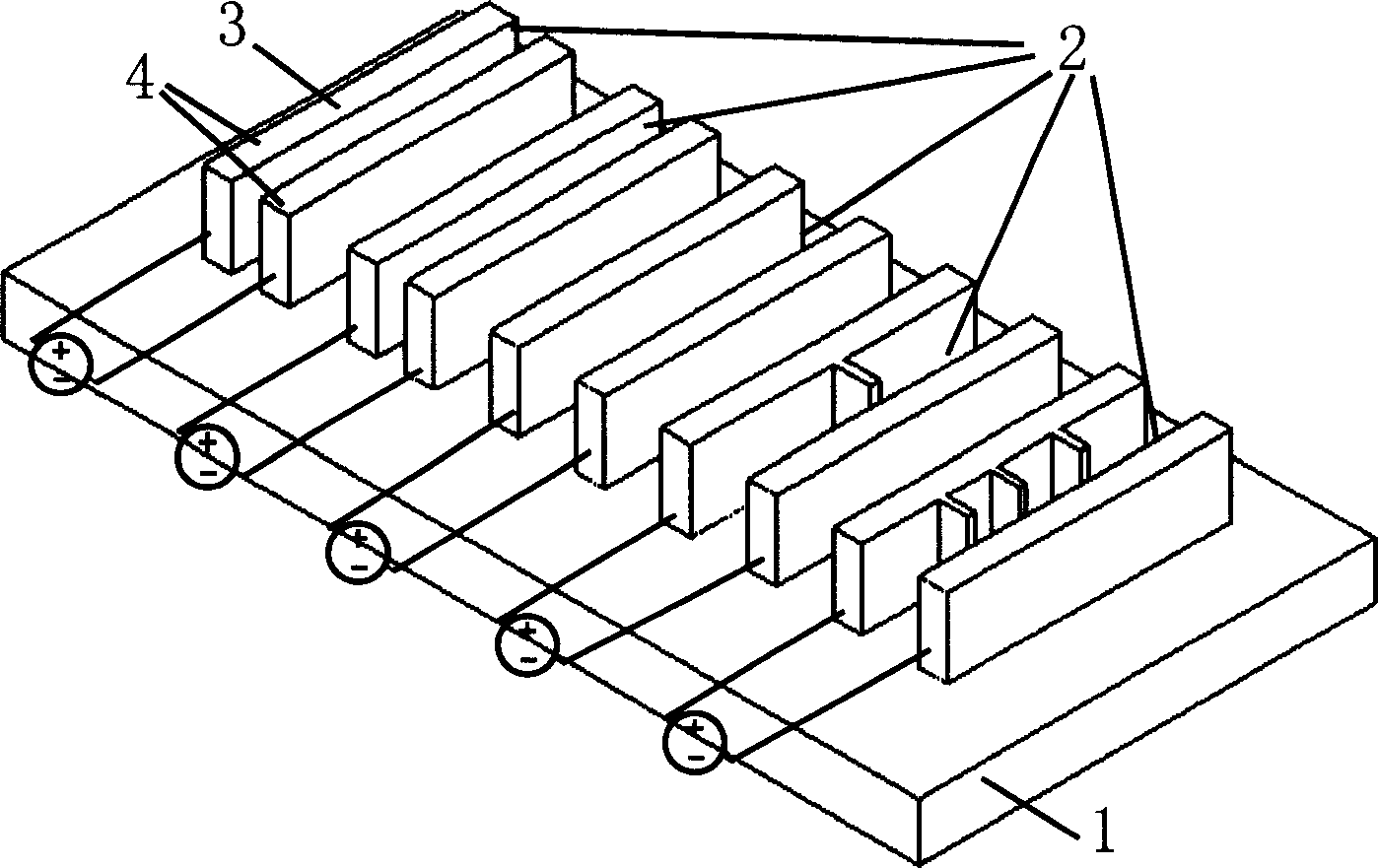

[0012] Such as figure 1 As shown, the present invention includes a substrate 1, a microelectrode array 2, a microelectrode bar unit 3, and a sensor unit 4. The microelectrode array 2 is arranged on the substrate 1, and the microelectrode array 2 includes multiple Each pair of adjacent negative and positive electrode strips constitutes a pair of sidewall electrodes, as a structure for generating a controllable electric field, thereby forming a sensor unit 4, and a plurality of sensor units form a microelectrode array, according to each sensor unit. Whether the plane geometric shape and spacing of adjacent negative and positive electrode strips are the same, the sensor unit is divided into equal units and different units. The same unit means that the plane geometry and spacing of adjacent negative and positive electrode strips in the two units are exactly the same, different A unit means that the planar geometry or spacing of adjacent cathode and anode strips in two units are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com