Semi-automatic production process of savoury chicken

A production method and semi-automatic technology, which is applied in food preparation, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of small product quantity, high local temperature, and poor hygienic conditions, and achieve stable product quality and good production environment. Hygienic and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

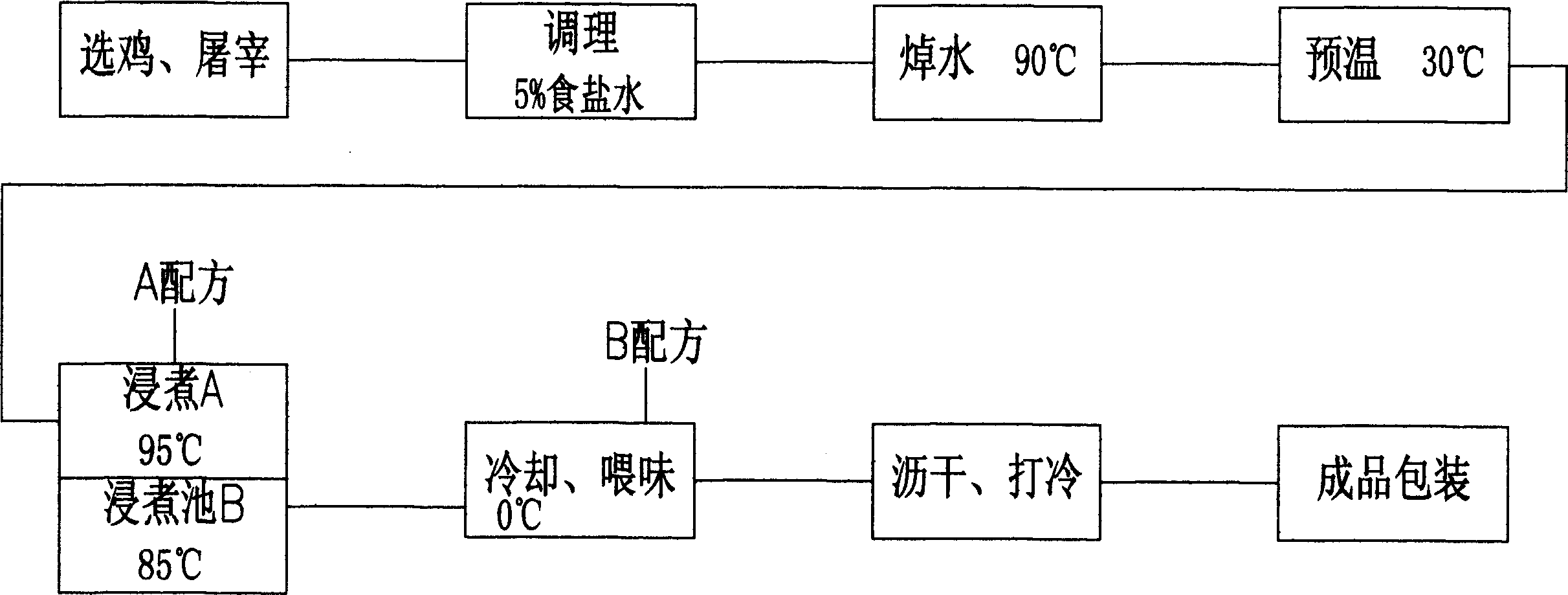

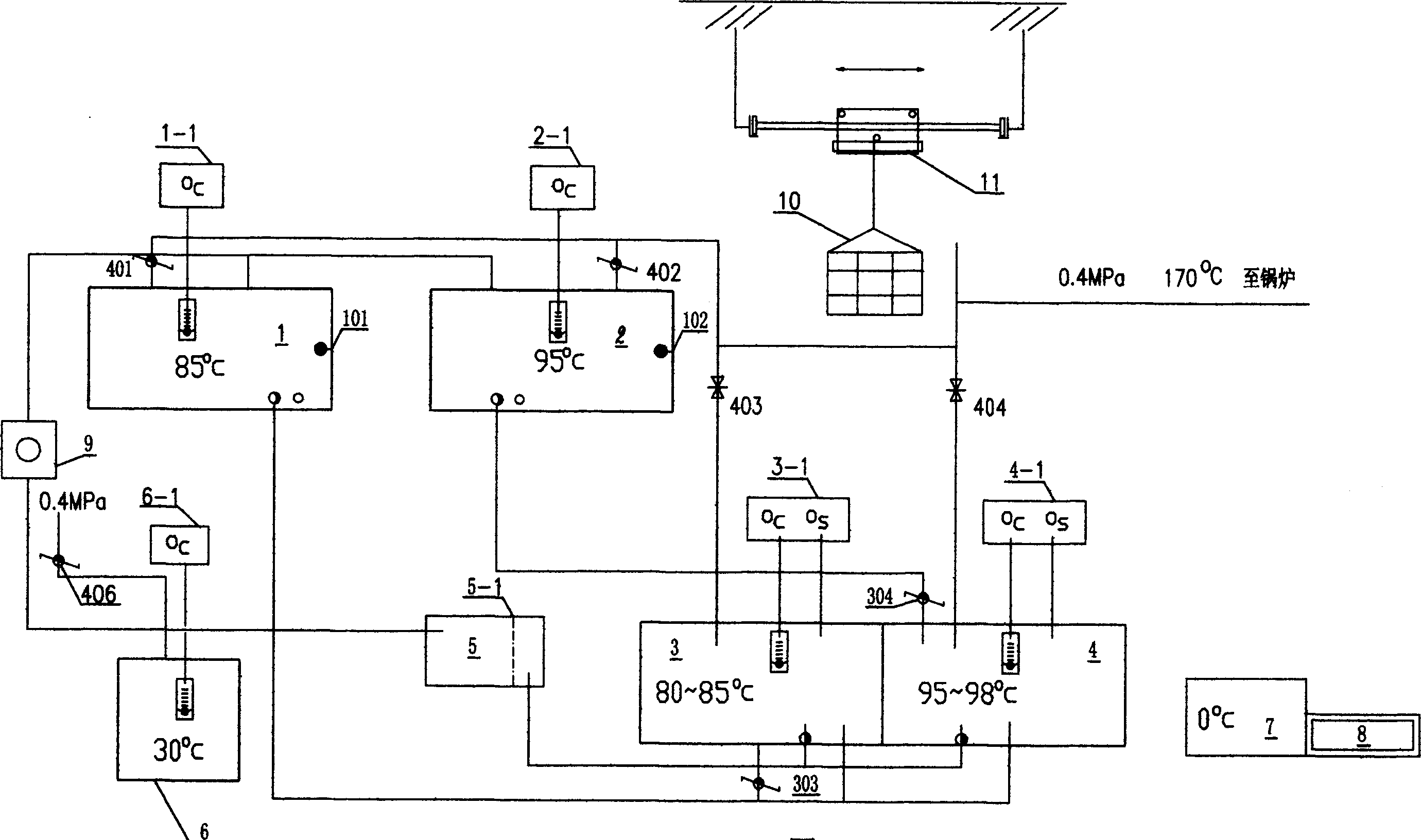

[0024] The production method of the present invention comprises the following steps:

[0025] 1. Selection and slaughter: select the chicken that has passed the health inspection; the back of the bare chicken after slaughter is plump; there is no large area of flowering body or black spots; no red head or black head; the chicken skin is not cracked; the butter degree is 3-5 degrees; Larger pores. Freshly slaughtered chickens should be used instead of refrigerated or frozen chickens.

[0026] 2. Conditioning: Clean the mouth and inner chamber, remove grease, lungs and other viscera; bend the chicken feet into the chicken belly; soak the blood in the bone marrow with normal temperature salt water (5%).

[0027] 3. Blanching water: soak three times in hot water at 90°C for a short time until the chicken skin turns pale yellow to remove fishy smell and dirt; put the chicken in hot water for a short time to make the protein on the surface of the product immediately Solidify and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com