Device and method processing substrate

A substrate processing device and substrate technology, applied in cleaning methods and tools, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of metal film damage, uneven impact energy of ice particles and substrate surface, uneven treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

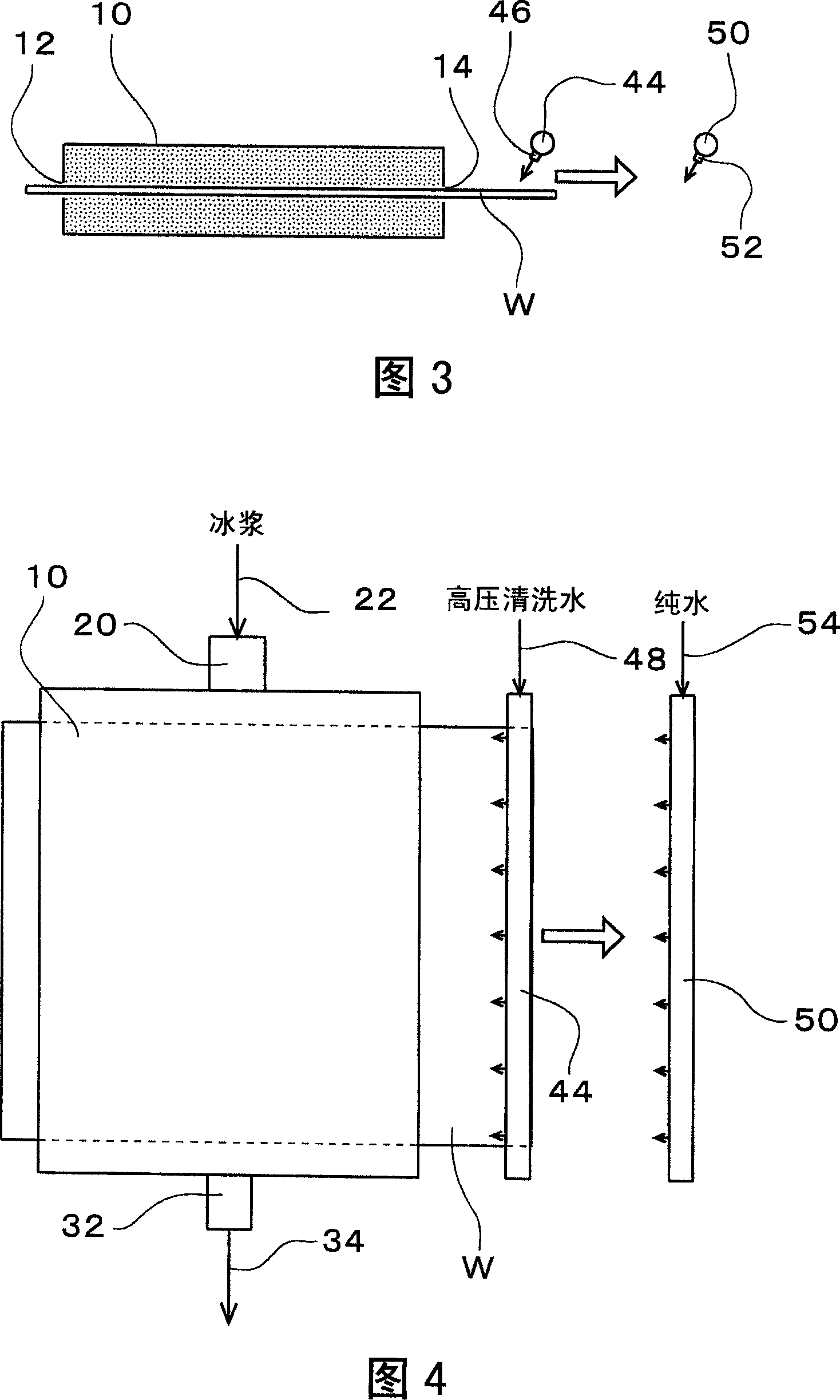

[0039] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

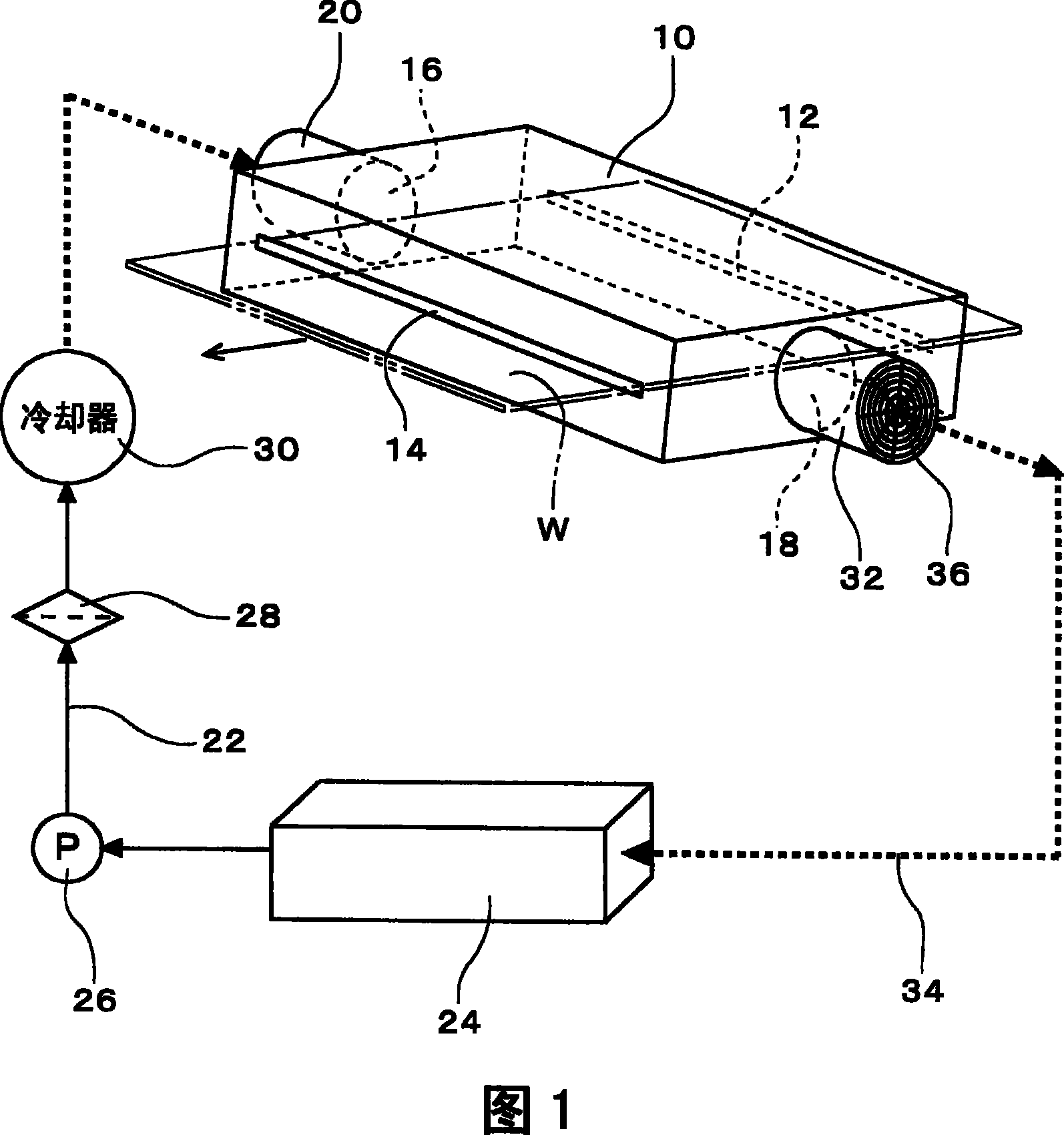

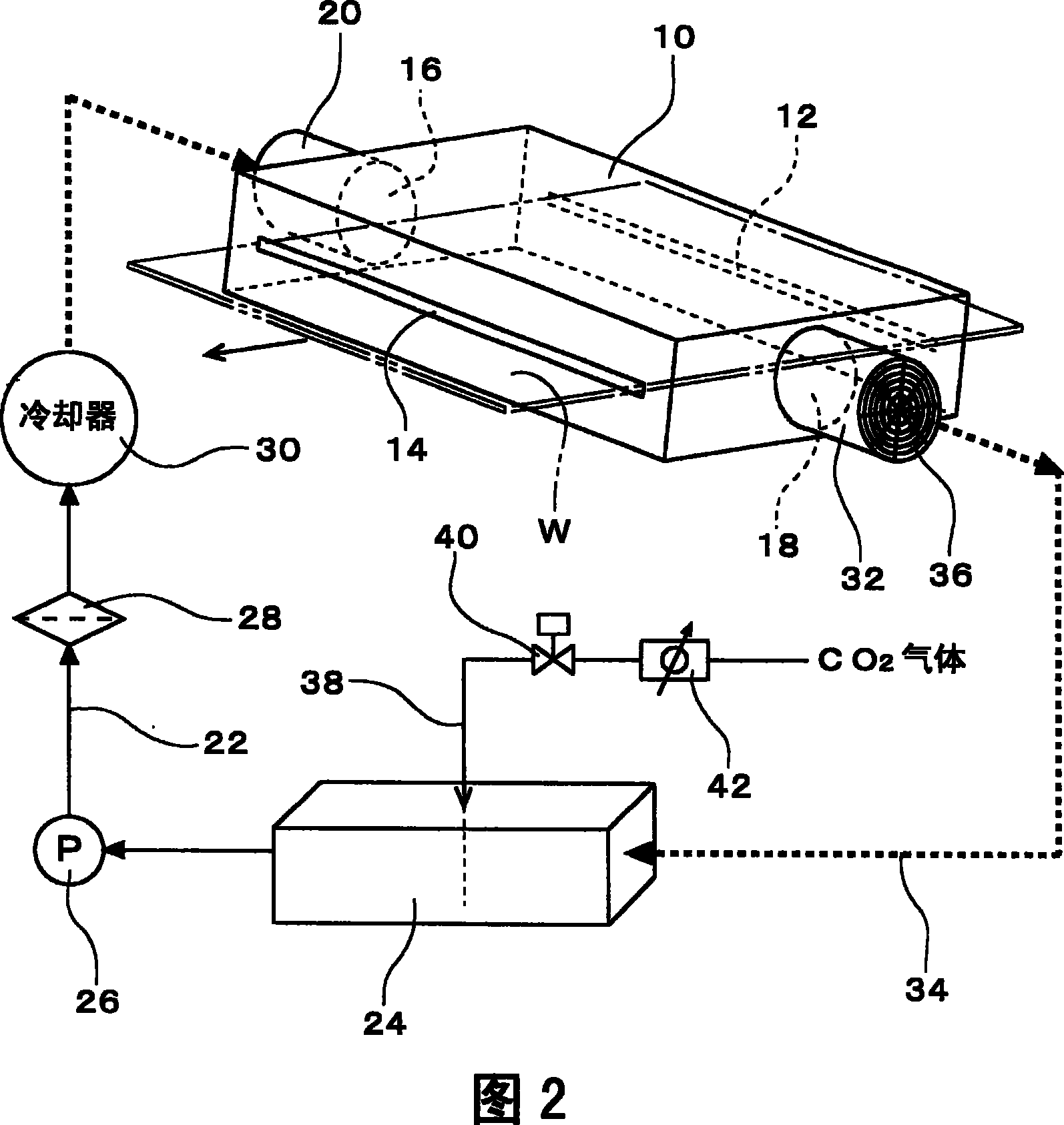

[0040] figure 1 An example of an embodiment of the present invention is schematically shown, and is a perspective view of a schematic configuration of a substrate processing apparatus, in this example, a substrate cleaning apparatus.

[0041] This substrate cleaning apparatus has a cleaning tank 10 formed of a sealed rectangular housing in which the substrate W is cleaned. The planar shape of the cleaning tank 10 is a rectangular shape having a width larger than the width of the substrate W and a length smaller than the length of the substrate W in the transfer direction. In the cleaning tank 10, a substrate carrying port 12 and a substrate carrying port 14 are provided on a pair of side faces facing each other, and a cleaning solution containing ice particles, such as pure water (hereinafter, A supply port 16 and a discharge port 18 referred to as "ice slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com