Permanent-magnet eddy current retarder for vehicle

A permanent magnet eddy current and retarder technology, which is applied in the direction of permanent magnet clutches/brakes, etc., can solve the problems of complex structure of hydraulic retarder, high heat generation of electromagnetic coil, long action response time, etc., and achieve light weight, Low energy consumption and good magnetic sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

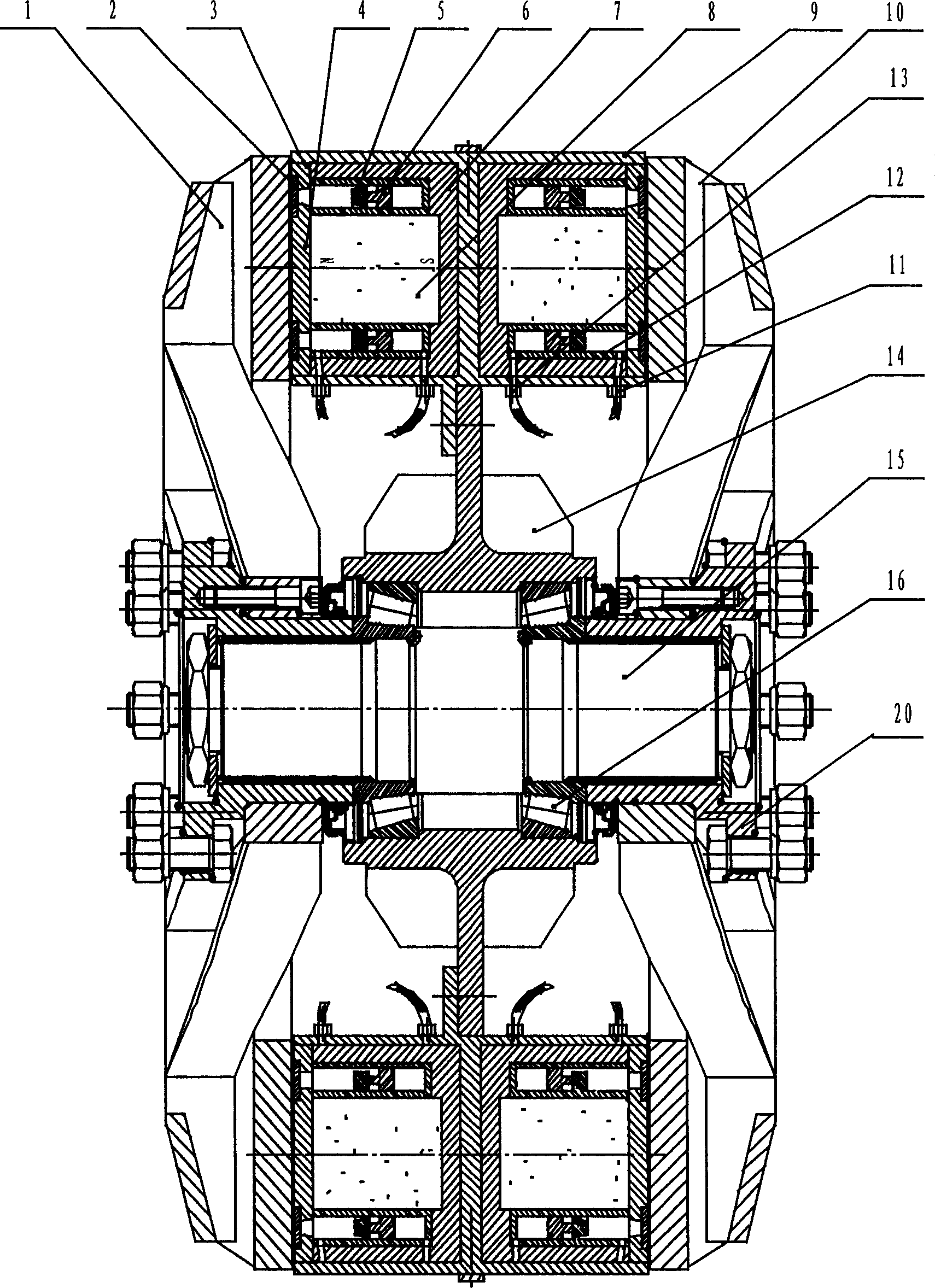

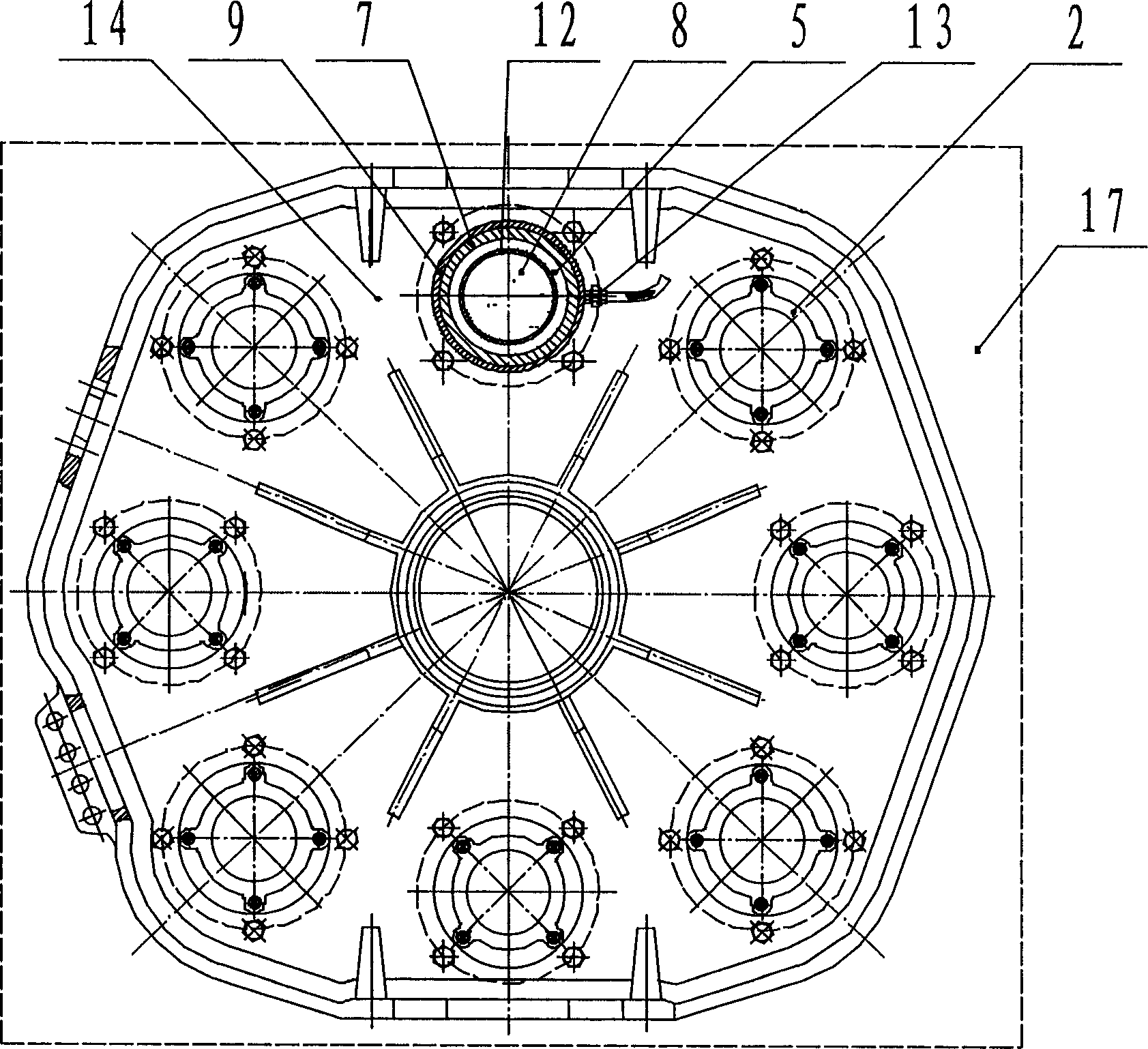

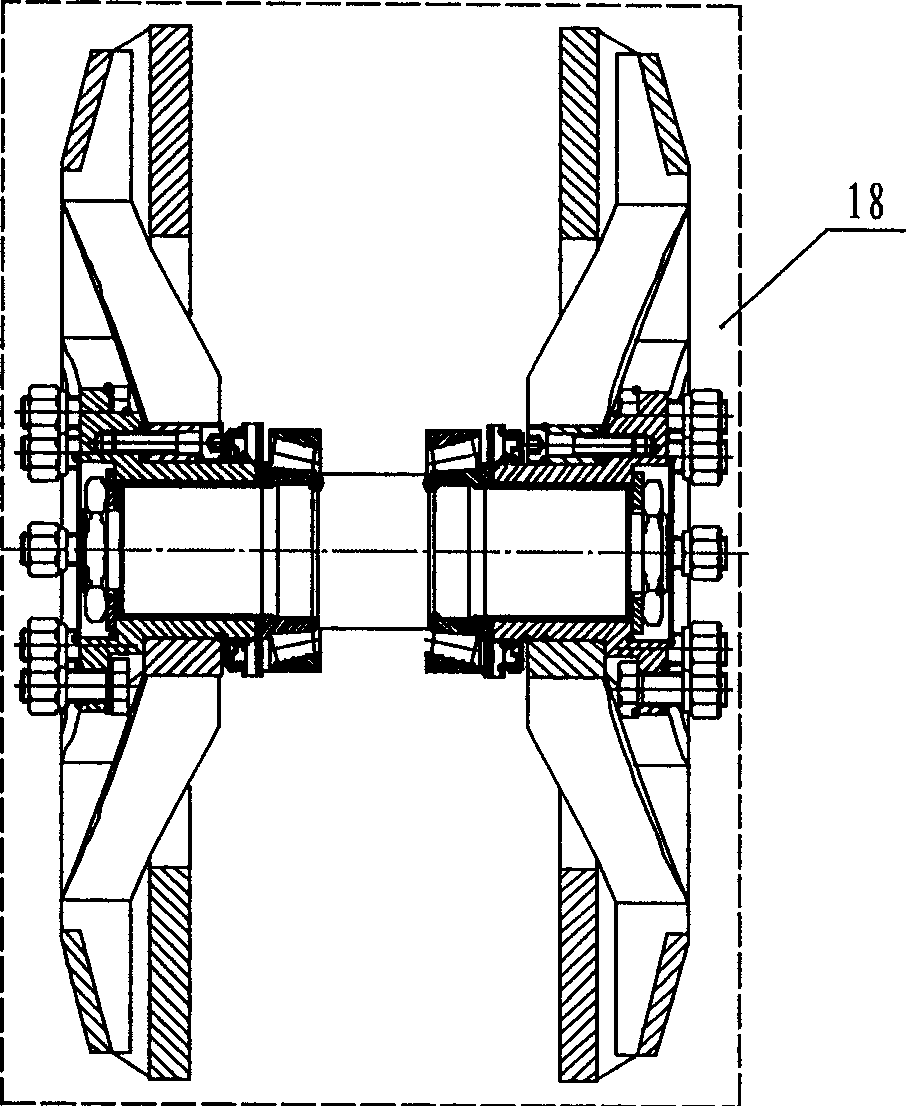

[0021] Embodiments of the present invention are as follows, see Figure 1~5 . The permanent magnet eddy current retarder for vehicles is composed of a stator assembly 17 and a rotor assembly 18. The stator assembly 17 is composed of a stator support 14 and 8 sets of magnetic switch assemblies 19 fixed on the stator support 14 along the circumferential direction. 1 and the large end faces of the right rotor disk 10 are parallel to the end faces of the magnetic switch assembly 19 and have an air gap. The magnetic switch assembly 19 is mainly composed of a NdFeB permanent magnet 8, a magnetic cylinder 7, a movable magnetic ring 5, a magnetic plate 4, and a magnetic ring 3, and is fixed with the pressure plate 2 to form a closed cavity, and the left air valve 11 and the right air valve 13 are respectively located on the left and right sides of the piston ring 6; the bottom of the inner side of the open magnetic cylinder 7 is provided with a step counterbore matching the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com