Package structure of silicon capacitor microphone and fabrication method thereof

A packaging structure and microphone technology, applied in the field of microphones, can solve problems such as bonding defects, deformation, and reduced bonding characteristics, and achieve the effects of reducing product damage, reducing manufacturing costs, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

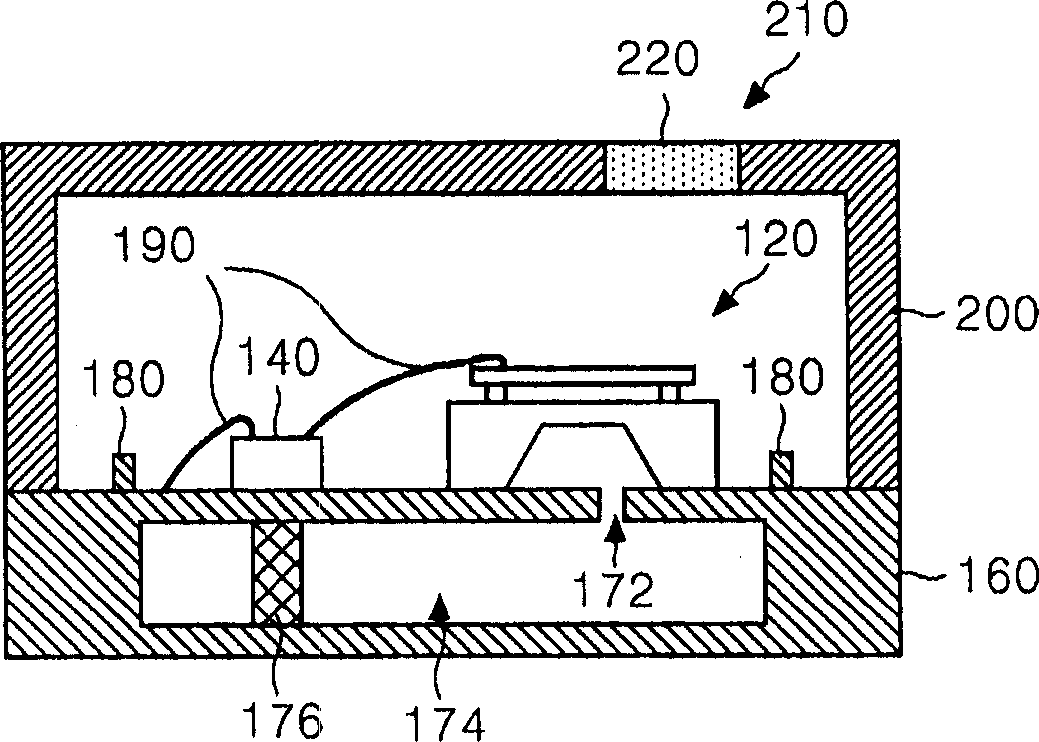

[0031] The above objects and other objects, features and advantages of the present invention will be described in detail below with reference to the accompanying drawings.

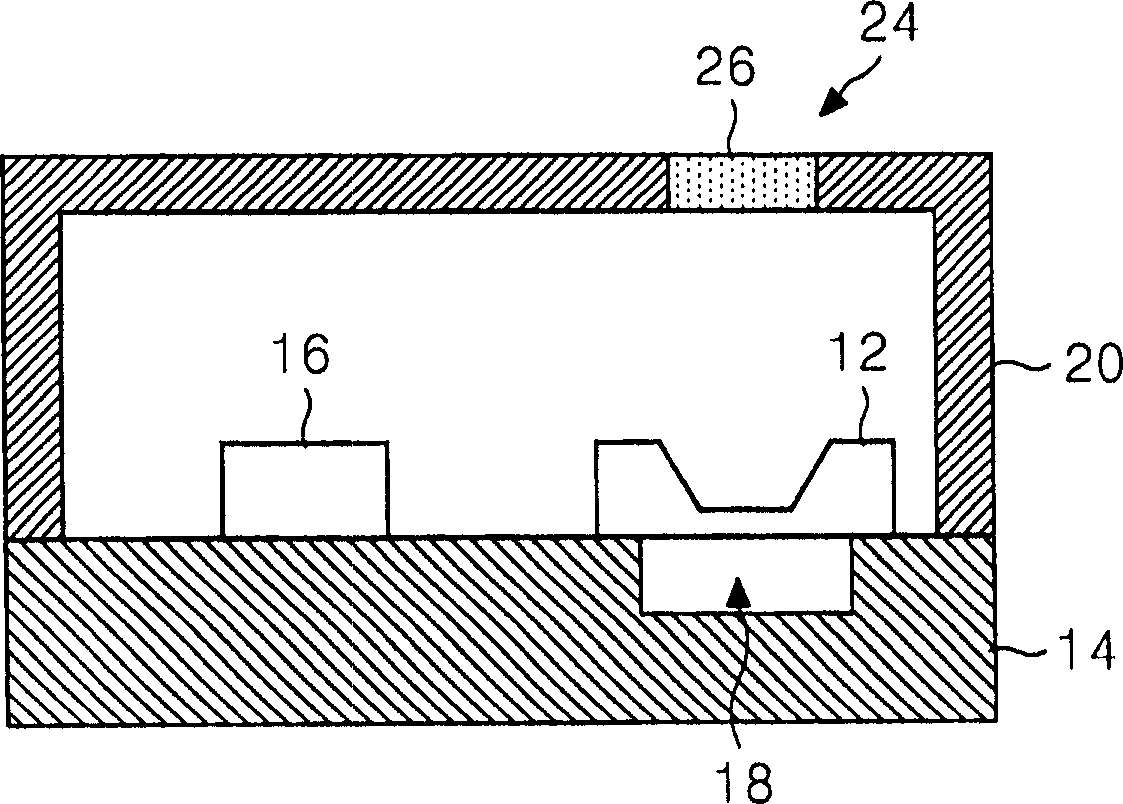

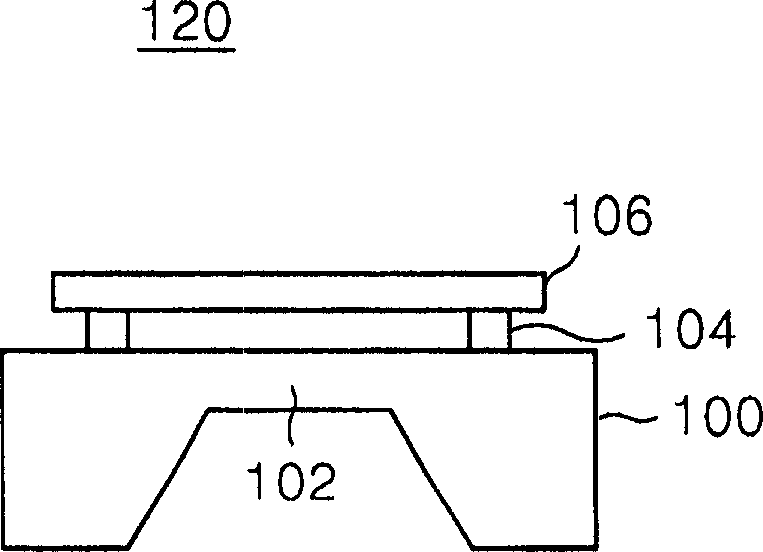

[0032] figure 2 is a cross-sectional view showing the structure of the condenser microphone.

[0033] refer to figure 2 , the gasket 104 and the vibrating plate 106 are stacked on the first side of the silicon wafer 100 , and a portion of the second side of the silicon wafer is etched to form the back plate 102 . The gasket 104 is formed by stacking an insulating film on the silicon wafer 100 and then patterning the insulating film. The vibration plate 106 is formed thereon with a conductive film. According to the illustrated structure, although the vibration plate 106 is disposed on the silicon chip 100, the positions of the vibration plate 106 and the back plate 102 can be exchanged when the vibration plate 106 and the back plate 102 are opposed to each other with the gasket 104 therebetween.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com