Impeller with staggered leaf on front edge

A blade leading edge and blade technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the complexity of working equipment or systems, increase additional expenses, and increase total investment and other issues, to achieve obvious social and economic benefits, low cost, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

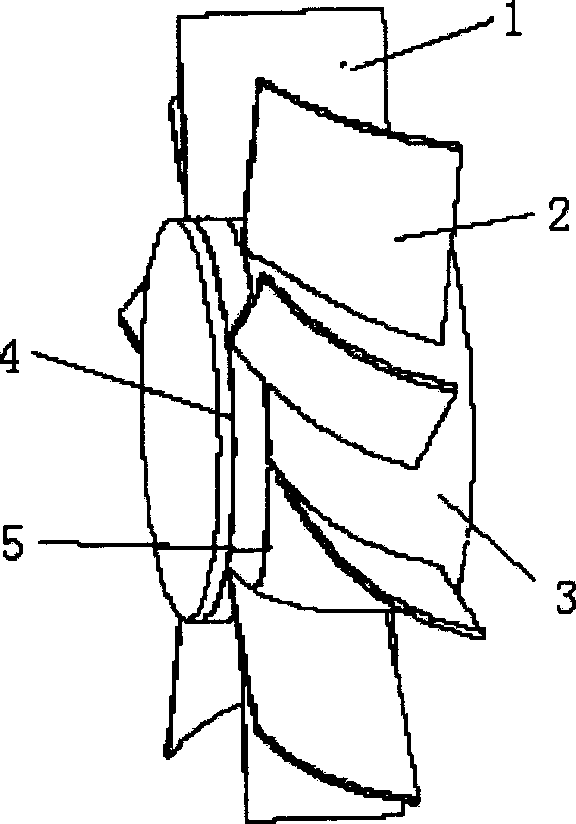

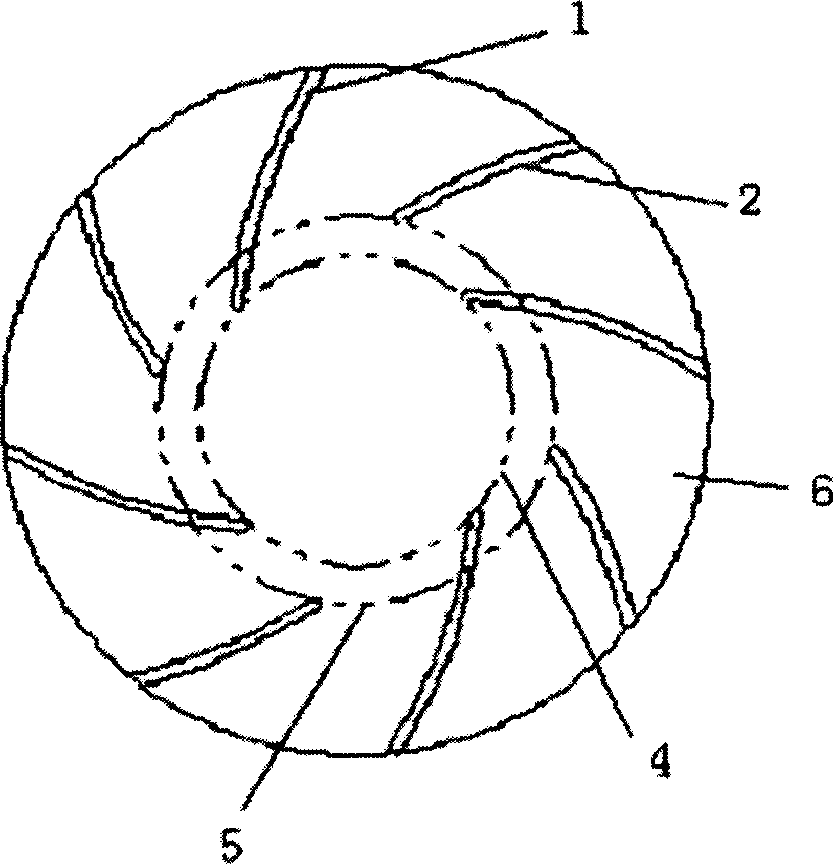

[0018] The number of blades of the impeller designed by the present invention is an even number, and the blades of the impeller are divided into two rows—odd row blades and even row blades, and the blades are installed on the hub of the axial flow fan at equal intervals along the circumference, or on the wheel disk of the centrifugal fan , where the leading edges of the odd-numbered and even-numbered blades are staggered, that is, the leading edges of the odd-numbered blades and the even-numbered blades are staggered back and forth, and the distance between the leading edges of the two rows of blades satisfies the two The condition in which the phases of sound waves are opposite or differ by half a wavelength.

[0019] figure 1 It is a schematic diagram of the structure of the axial flow fan impeller adopting the displacement of the lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com