Semiconductor light-emitting device

一种发光元件、半导体的技术,应用在半导体器件、电气元件、电固体器件等方向,能够解决难以形成接触电阻、小高反射率、制约大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

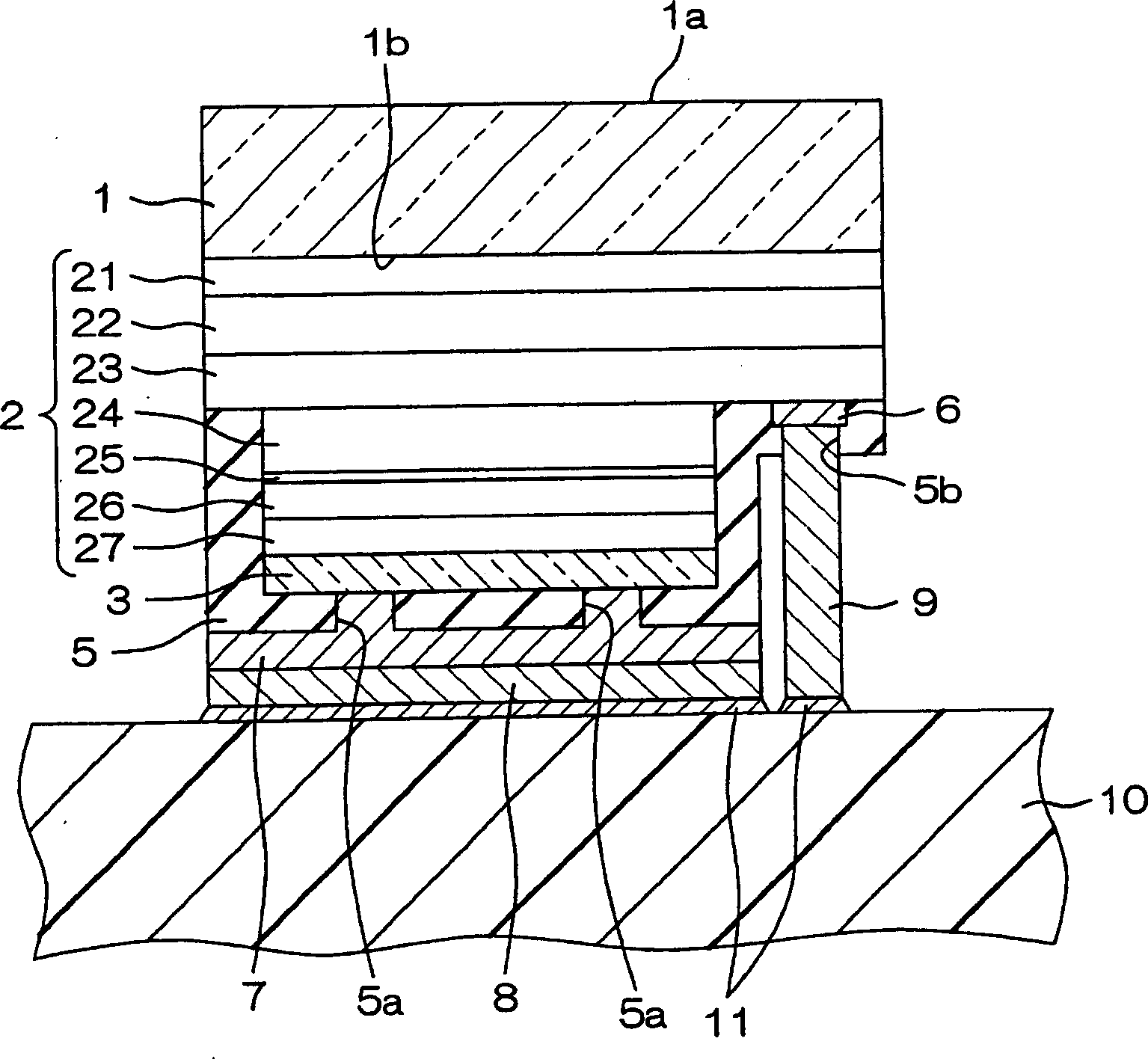

[0032] figure 1 It is a cross-sectional view diagrammatically showing the structure of a light emitting diode element according to an embodiment of the present invention. This light emitting diode element is a flip-chip type element, and includes: a sapphire substrate 1 as a transparent substrate, an InGaN semiconductor light emitting portion 2 formed on the sapphire substrate 1 , and a side of the InGaN semiconductor light emitting portion 2 opposite to the sapphire substrate 1. The P-side transparent electrode 3 formed by covering the surface. In the sapphire substrate 1, one of the surfaces is used as the light extraction surface 1a, and the other surface thereof is used as the element formation surface 1b. An InGaN semiconductor light emitting portion 2 is formed on the element forming surface 1b.

[0033] The sapphire substrate 1 is an insulating substrate transparent to the emission wavelength (for example, 460 nm) of the InGaN semiconductor light emitting portion 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com