Supersonic dewatering method for mud

An ultrasonic and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of high cost, high cost and complicated process, and achieve the effect of reducing cost, good effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

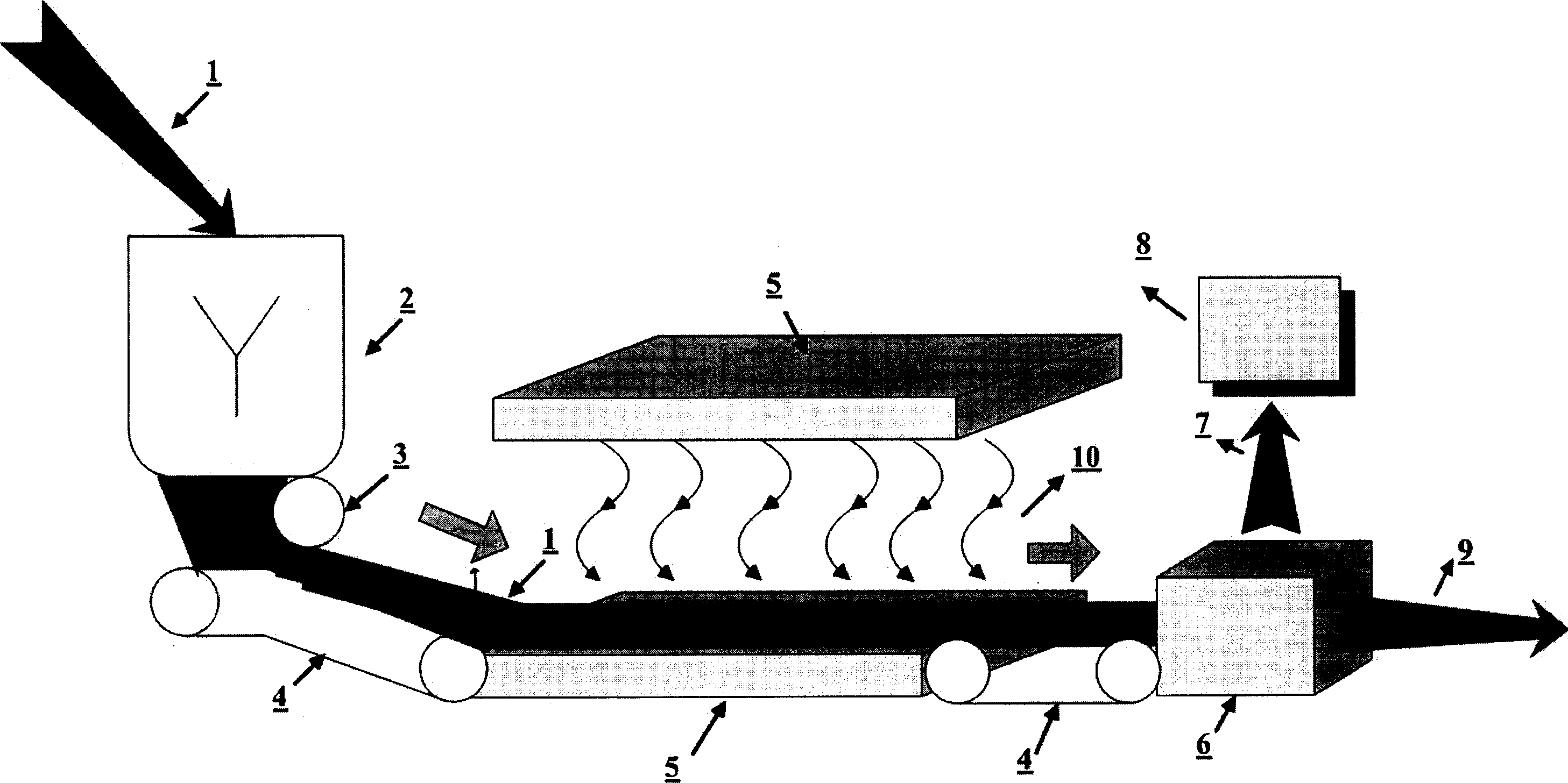

Method used

Image

Examples

Embodiment 1

[0019] An urban sewage treatment plant in Qinhuangdao adopts the activated sludge method for treatment, and the properties of the dewatered sludge are shown in Table 2:

[0020] moisture content

(%)

Volatile content

(%)

Ash content

(%)

(%)

lower calorific value

(kcal / g)

84.20

40.95

56.66

2.39

457

[0021] The moisture content of the treated sludge is shown in Table 3:

[0022]

Embodiment 2

[0024] An urban sewage treatment plant in Nanshan District, Shenzhen, adopts the oxidation ditch process to treat sewage. The properties of dewatered sludge are shown in Table 4:

[0025] moisture content

[0026] The moisture content of the treated sludge is shown in Table 5:

[0027]

[0028] From the above examples, it can be concluded that after the sludge is treated with ultrasonic waves, the water content drops from 80-85% to 60-70%, which lays a good foundation for the later recycling of sludge. The energy consumption of the present invention mainly comes from the energy consumption of the ultrasonic generator and other supporting facilities, all of which are mechanical equipment with low power and low energy consumption. Compared with other dehydration technologies, the cost and energy consumption will be greatly reduced, so there is a comparative advantage. Good market prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com