Electro-blowing technology for fabrication of fibrous articles and its applications of hyaluronan

一种透明质酸、电吹的技术,应用在纤维处理、短纤维形成、纤维化学特征等方向,能够解决批量生产不切实际等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

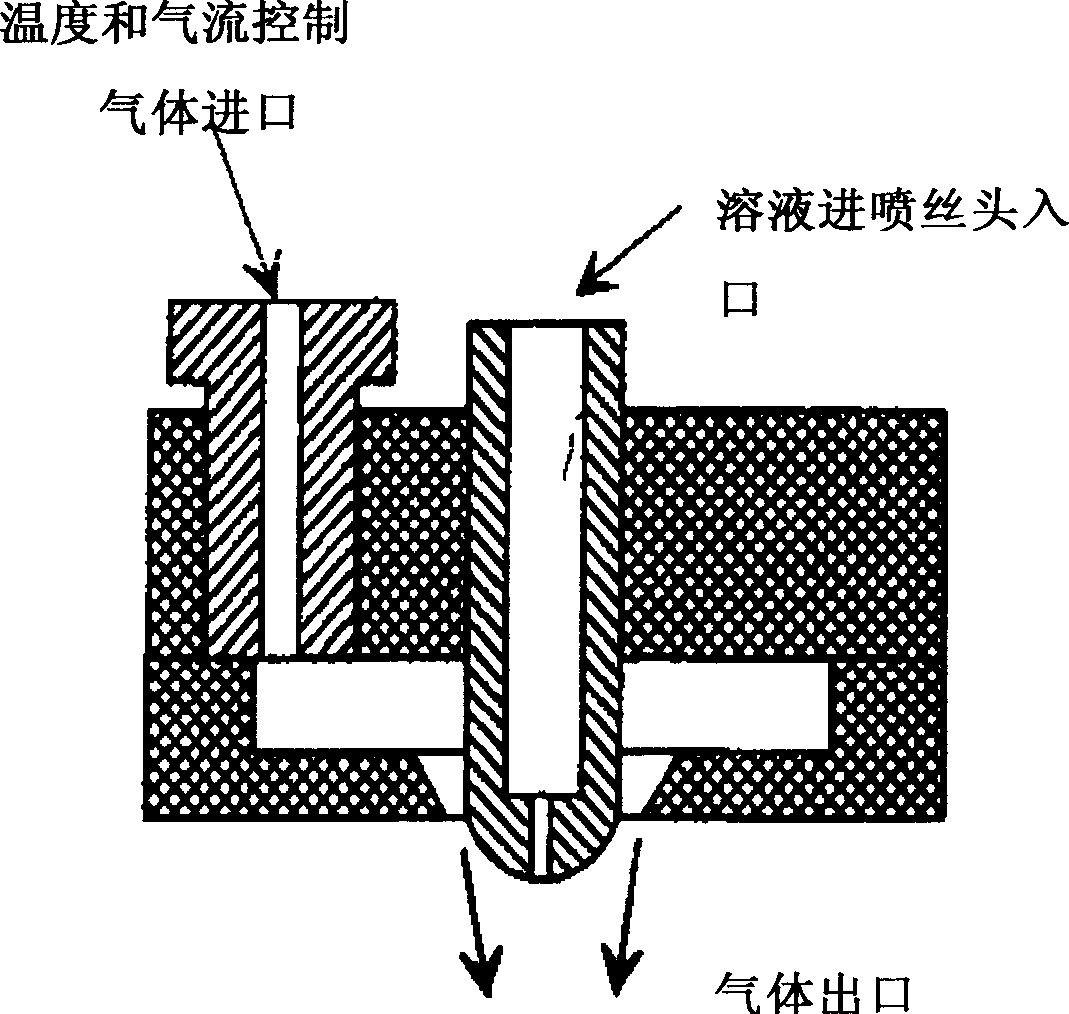

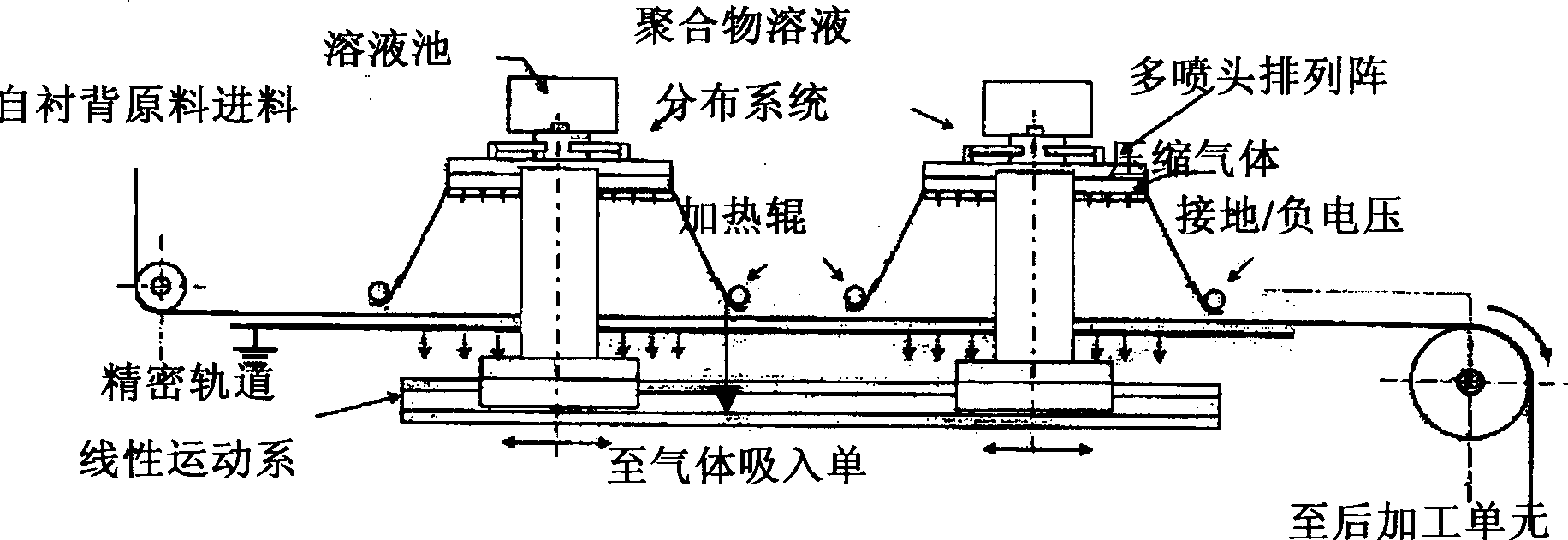

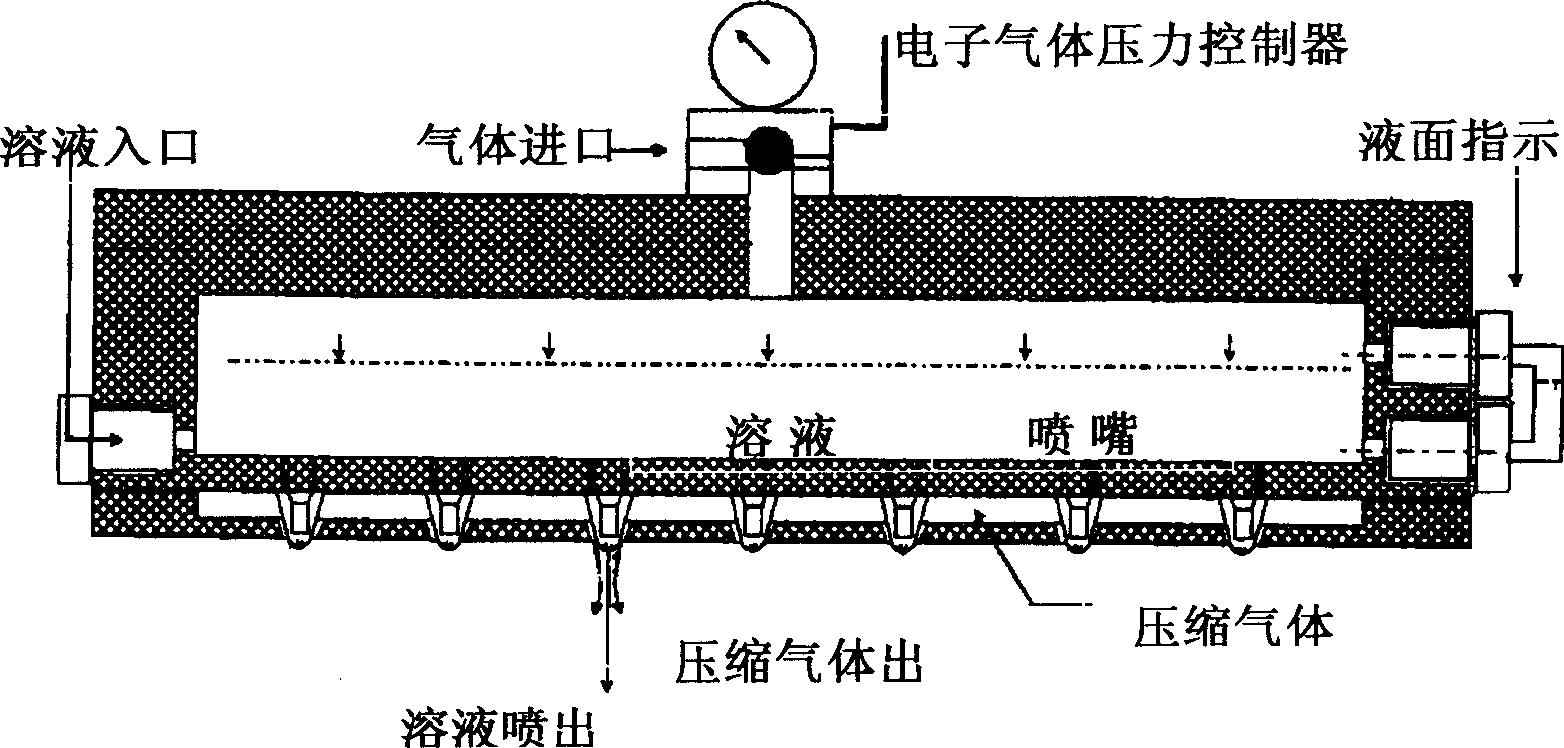

Method used

Image

Examples

Embodiment

[0097] After briefly describing the invention, it will be further understood through some specific reference examples. The examples provided herein are for illustrative purposes only and are not intended to limit process conditions unless otherwise stated.

[0098] Unless otherwise specified, the following are the hyaluronic acid (HA) electroblowing process conditions.

[0099] 1. Hyaluronic acid (HA) concentration: 2.5% (w / v), HA-C in acidic aqueous solution (MW: 3.5×10 6 )

[0100] 2. Solution feeding rate: 40μl / min

[0101] 3. Electric field voltage: 40kV

[0102] 4. Electrode spacing: 9.5cm

[0103]

HA sample

Preparation

molecular weight

NaCl content

(wt%)

(Pa·s at 1s -1 )

HA-C

Provided by Denka

3,500,000

0

21(0.7%)

HA-B

Provided by Denka

200,000

1.6

27(10%)

HA-A

Provided by Denka

45,000

2.1

13(25%)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com