Process for producing biodiesel

A technology of biodiesel and reaction products, which is used in fertilizers, biofuels, products, etc. made of biological waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

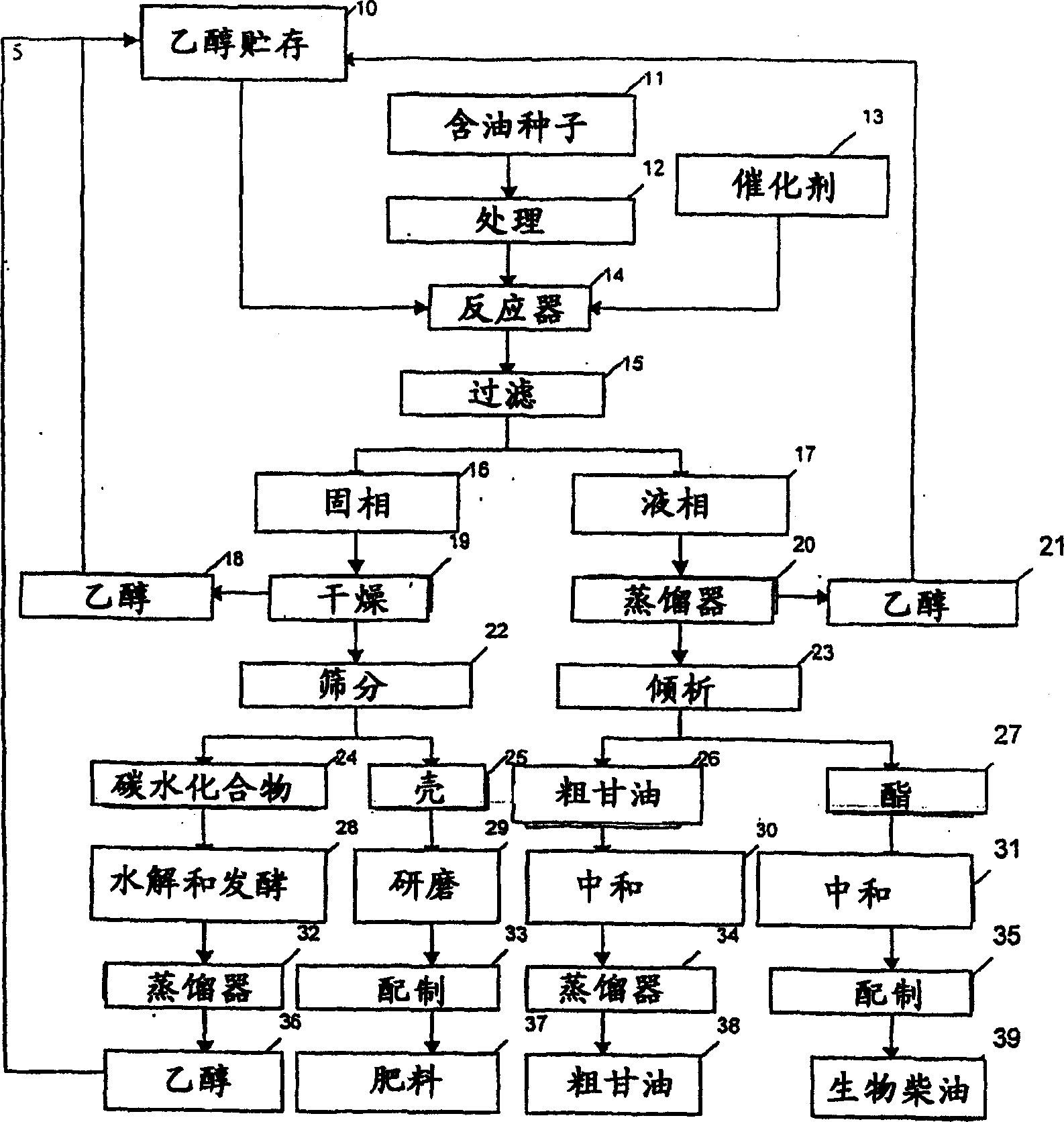

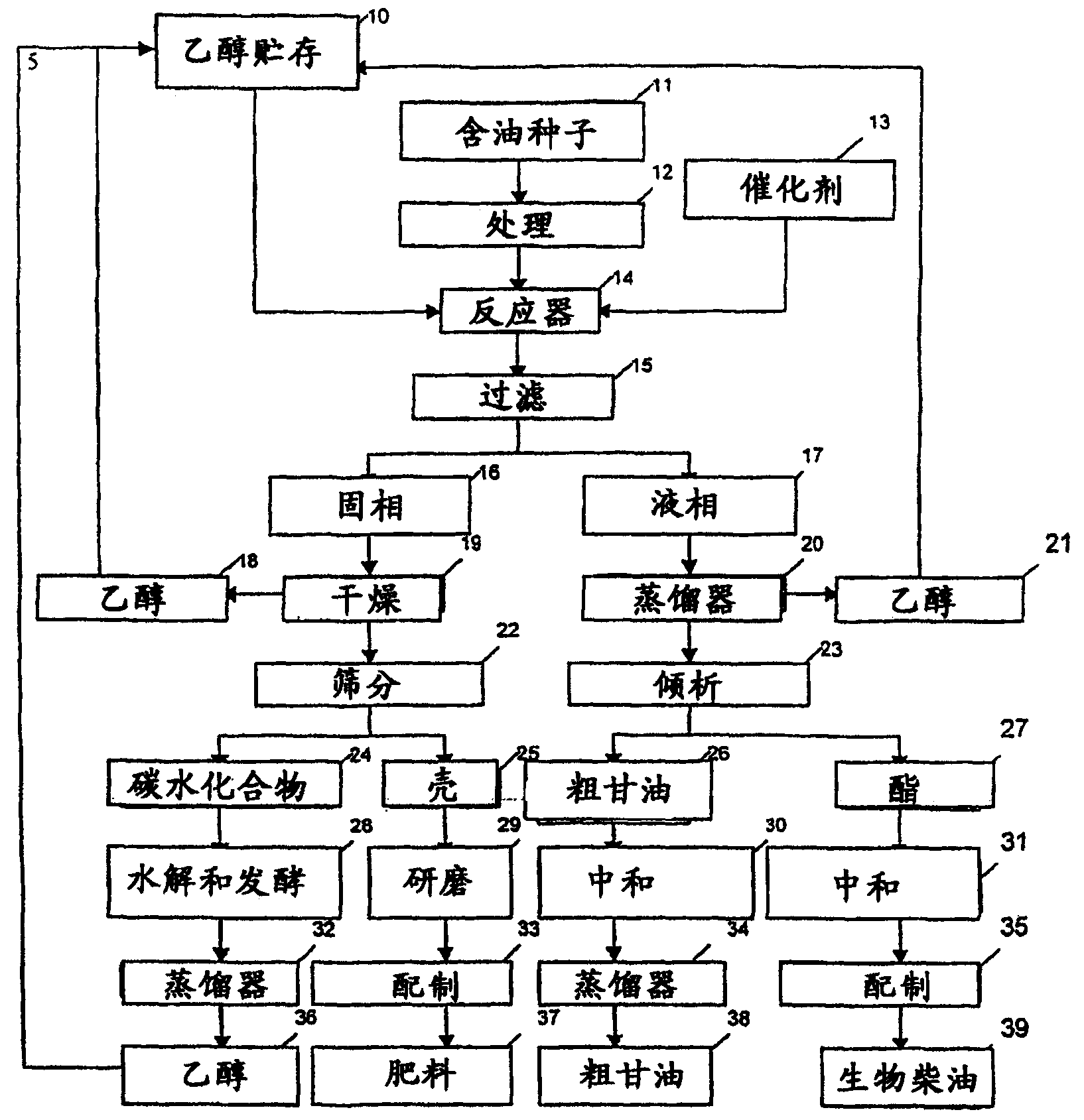

Image

Examples

Embodiment

[0050] At ambient temperature, 1000 g of raw castor bean seeds (Ricinus Communis L) of the Brazilian variety called "Bull Heart" processed as described above were added to the reactor along with 800 g of ethanol and crushed under vigorous stirring until The reaction mass is a flowing homogeneous suspension.

[0051] Then, 40 g of a sodium alkoxide catalyst was incorporated into the mixture, and transesterification of the seeds was carried out at atmospheric pressure and a constant temperature of 50° C. for 1 hour under moderate stirring and reflux.

[0052] The reactor was then cooled and fed to 40°C and filtered to obtain 600 g of solid phase and 1240 g of filtrate, after distillation of said filtrate at atmospheric pressure, 680 g of crude ethanol condensate and 560 g of ester, glycerol and other by-products remaining in the still were recovered A liquid residue consisting of a mixture.

[0053] Once transferred to a decanter, where it was kept at an ambient temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com