Intelligent absorption type transmission separating system with synchronous frequency conversion control

A technology of synchronous frequency conversion and transmission separation, applied in filtration separation, separation method, dispersed particle separation, etc., can solve the problems of strong corrosion and pollution, the water content of gypsum cannot always be guaranteed, and the dispersion of control objects, etc., to achieve convenient operation and realization. On-site and remote automatic switching control, the effect of preventing corrosion and contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

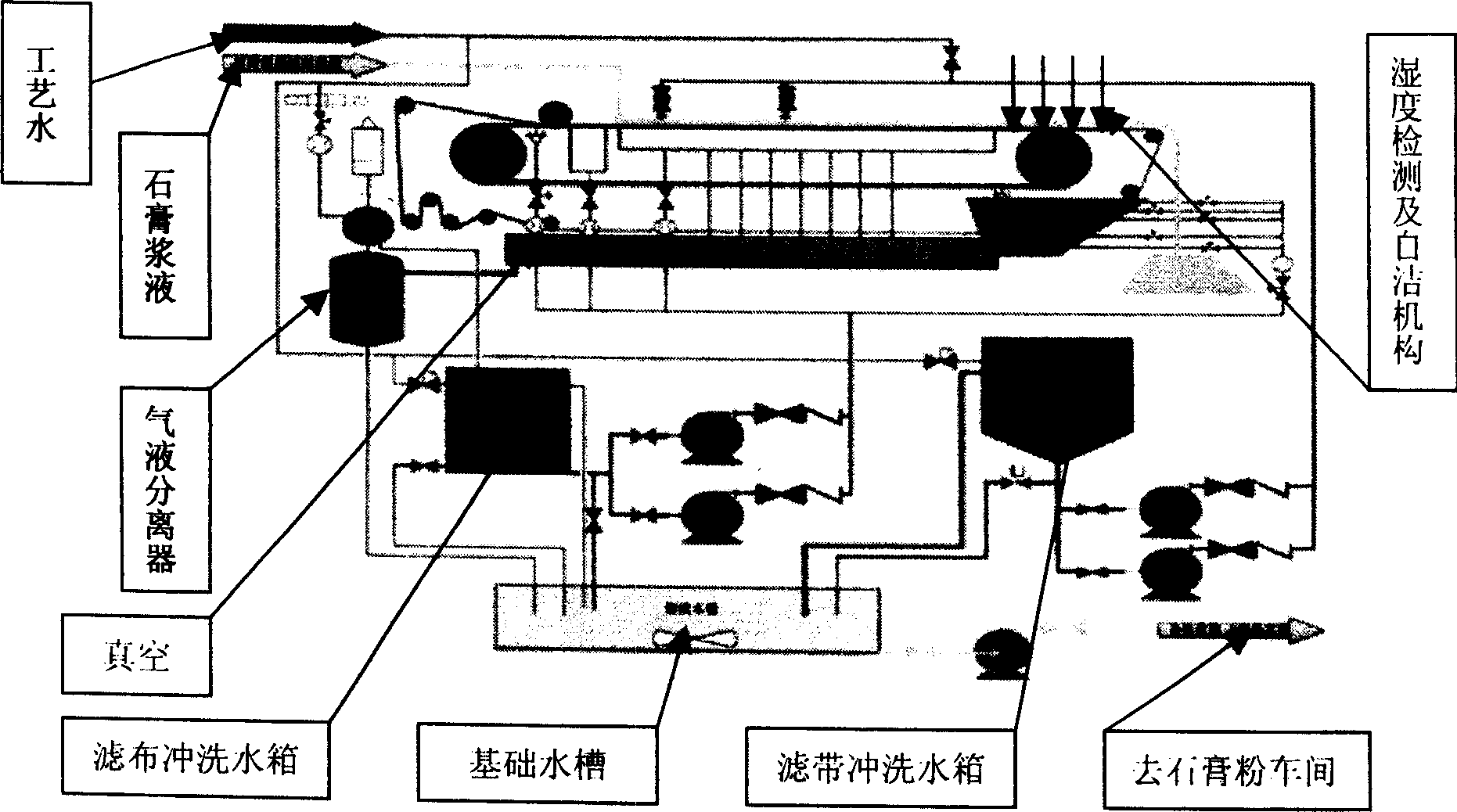

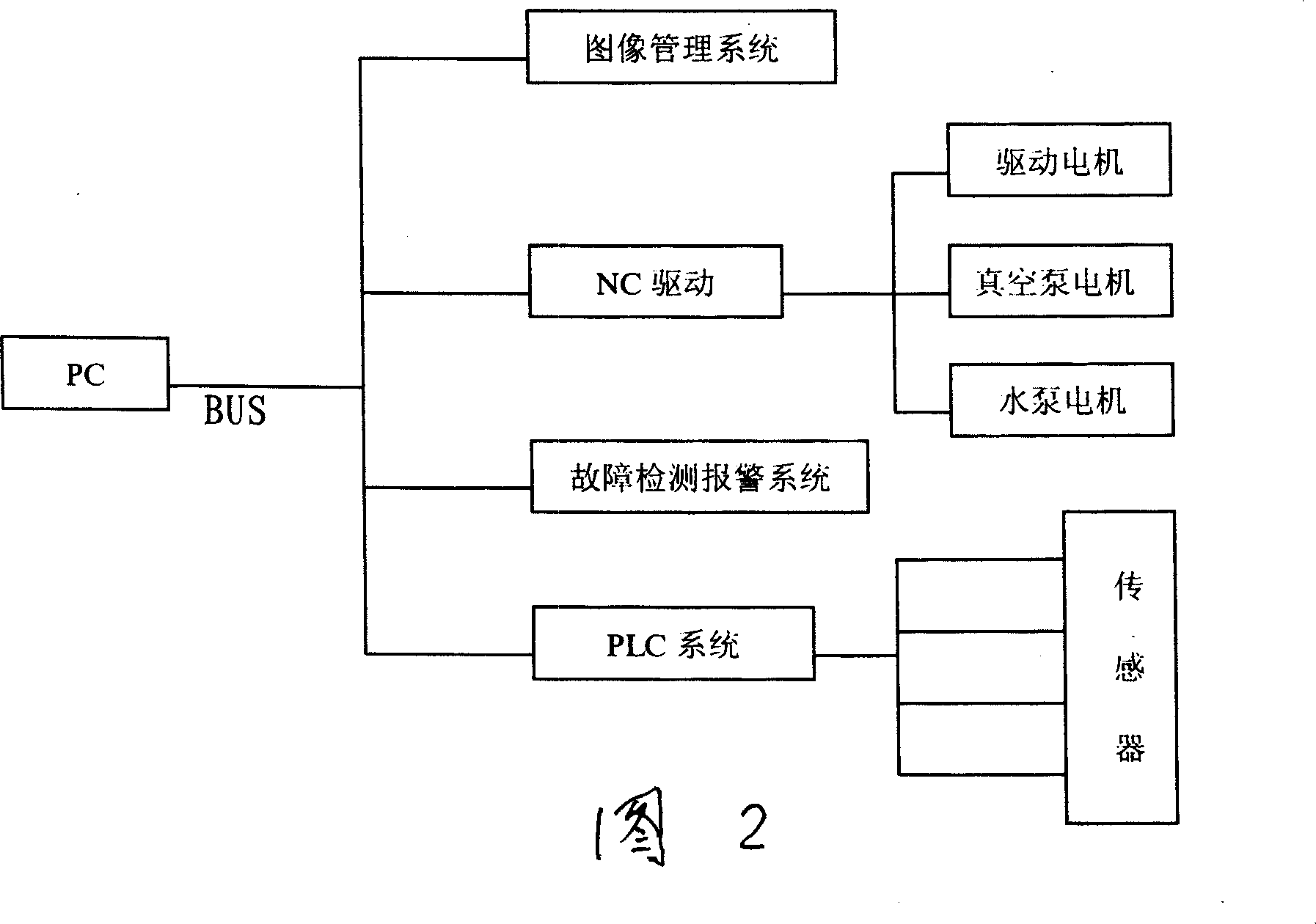

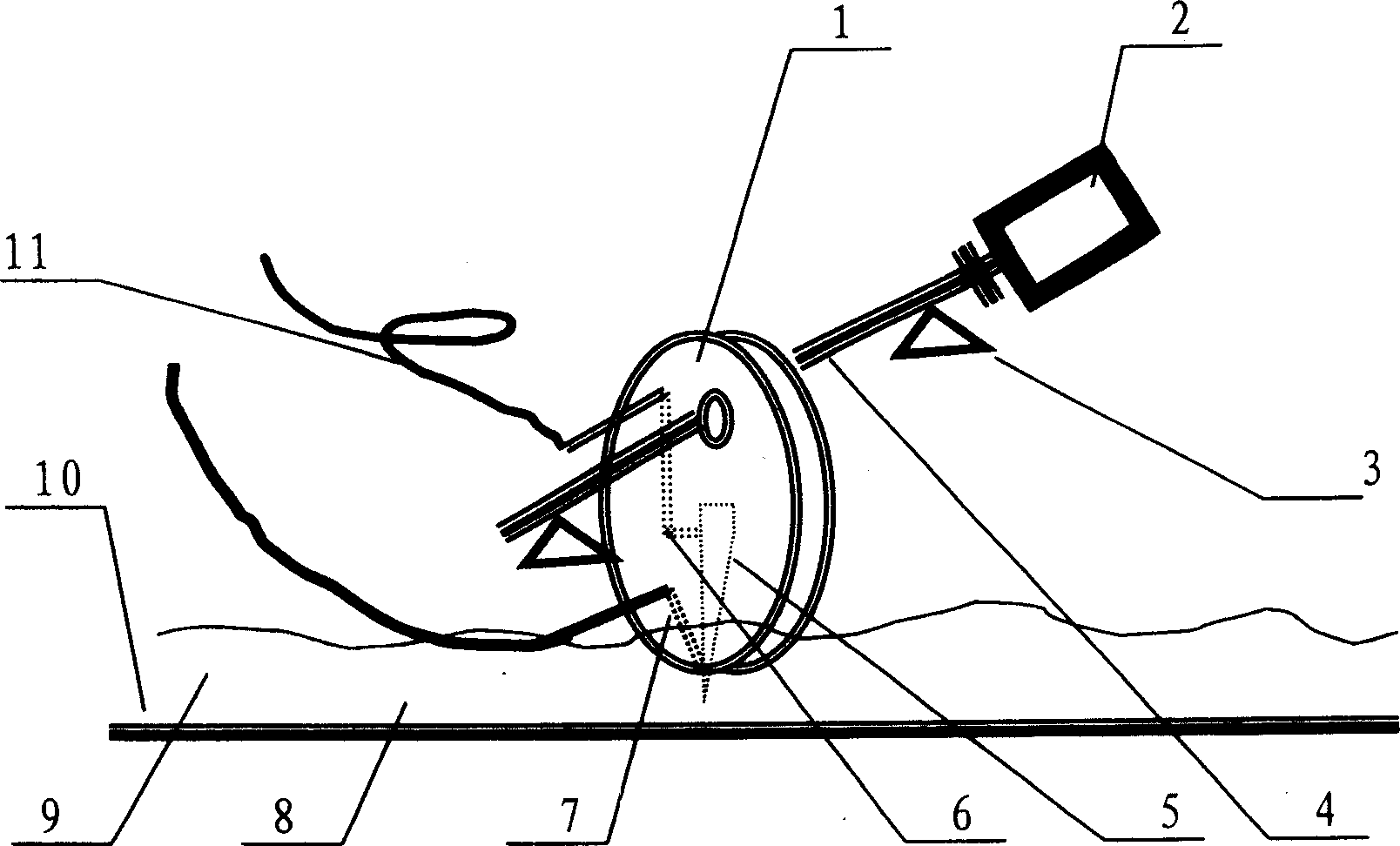

[0010] For the present invention is based on the existing frequency conversion control adsorption type transmission separation system, including the transmission and filter mechanism composed of filter belt and adhesive tape, frequency conversion control drive mechanism, and develops a control system with PC as the core to realize the control of drive motors, vacuum pumps, etc. Automatic digital control of motors, water pump motors, etc., to facilitate fault diagnosis and automatic control of ingredients; equipped with dedicated image sensors and multi-level humidity sensors, it can monitor the moisture content of gypsum at different detection points in real time online according to the time set by the system Detection, through online monitoring, synchronously and automatically adjusts the speed of the driving mechanism to ensure that the moisture content of the gypsum is stable within 5%; the multi-level humidity sensor is equipped with an air purging device with a self-cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com