Preparation method of natural colour sesame oil

A natural color and natural pigment technology, which is applied in the field of preparation of natural color sesame oil, can solve the problems of limited application and promotion, single color, poor stability, etc., and achieve the effect of large adaptability, bright color and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

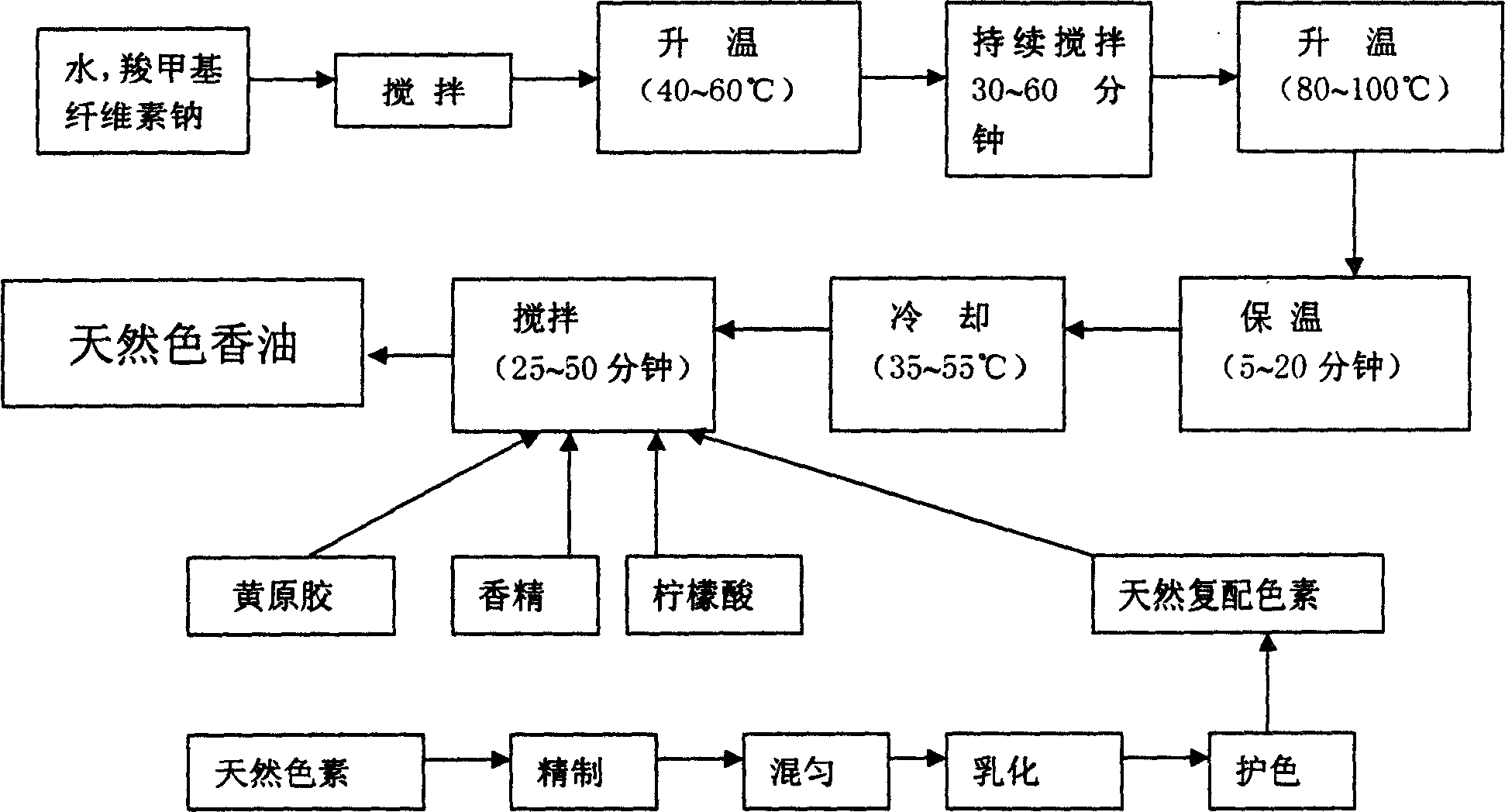

Method used

Image

Examples

Embodiment 1

[0027] Natural Strawberry Color Balm:

[0028] Natural pigment compounding process: first refine capsanthin and tea pigment respectively, mix them with 20% and 8% by weight respectively, add 20% modified starch, 18% phospholipid emulsifier, and 18% monoglyceride , 10% sucrose ester for emulsification, then add color-protecting agents: 3.5% tartaric acid and 2.5% phosphoric acid, and mix to obtain a natural compound pigment.

[0029] First add 85% of water and 3% of sodium carboxymethylcellulose according to the weight percentage and stir, and at the same time raise the temperature to 50°C, keep stirring for 50 minutes, then raise the temperature to 100°C, keep the temperature for 15 minutes, then cool to 50°C, add yellow 1.7% of raw gum, 0.25% of citric acid, 0.05% of strawberry essence and 10% of natural compound pigment were stirred for 30 minutes to obtain natural strawberry-colored sesame oil.

Embodiment 2

[0031] Natural Taro Sesame Oil:

[0032] Natural pigment compounding process: first refine the cochineal red pigment and gardenia yellow pigment respectively, mix them with 14% and 10% by weight respectively, add 18% of modified starch, 20% of phospholipid emulsifier, monoglyceride 20% of ester and 12% of sucrose ester are emulsified, then add color-protecting agent: 4.5% of tartaric acid and 1.5% of phosphoric acid, and mix well to obtain natural compound pigment.

[0033] First, add 90% of water and 2% of sodium carboxymethyl cellulose and stir, at the same time raise the temperature to 55°C, keep stirring for 30 minutes, then raise the temperature to 90°C, keep the temperature for 20 minutes, then cool to 55°C, add yellow 1.7% of raw gum, 0.25% of citric acid, 0.05% of taro essence and 6% of natural compound pigment were stirred for 25 minutes to obtain natural taro-colored sesame oil.

Embodiment 3

[0035] Natural Fragrant Orange Balm:

[0036] Natural pigment compounding process: after the gardenia yellow pigment is refined, 27.5% by weight is taken for mixing, and then 22% of modified starch, 18% of phospholipid emulsifier, 16.5% of monoglyceride and 10% of sucrose ester are added for emulsification , then add color-protecting agent: 3% tartaric acid and 3% phosphoric acid, and mix well to obtain natural compound pigment.

[0037] First add 80% of water and 5% of sodium carboxymethyl cellulose and stir, at the same time, heat up to 60°C, keep stirring for 45 minutes, then heat up to 85°C, keep warm for 10 minutes, then cool to 45°C, add yellow 2.7% of raw gum, 0.25% of citric acid, 0.05% of orange essence and 12% of natural compound pigment were stirred for 35 minutes to obtain natural fragrant orange sesame oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com