Iron-core magnetic gap processing technology of inductive ballast

An inductive ballast and magnetic gap technology, applied in the direction of inductors, transformers/inductor cores, circuits, etc., can solve the problems of electrical performance deterioration of inductive ballasts, safety accidents, large electromagnetic noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

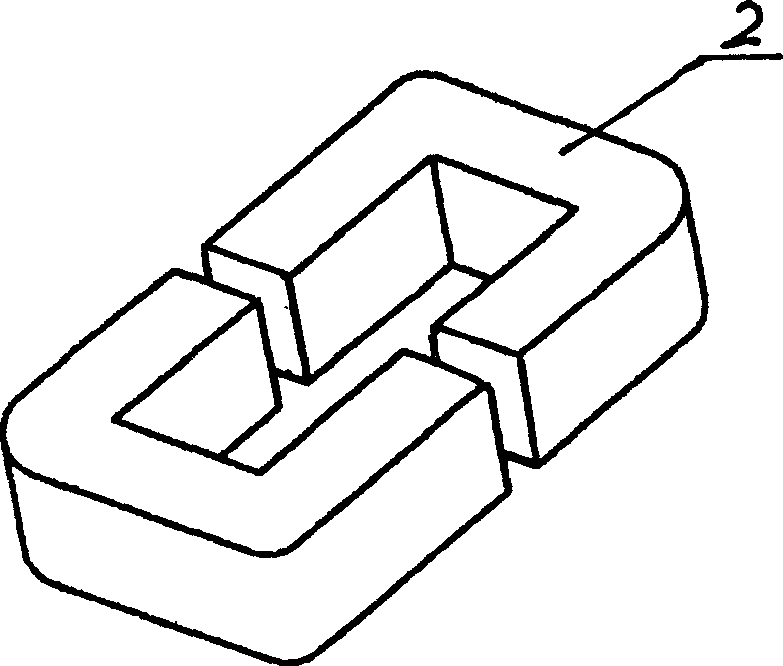

[0015] see Figure 5 As shown, a magnetic ballast magnetic gap processing technology, taking the double magnetic gap circular iron core as an example, the processing procedure is as follows:

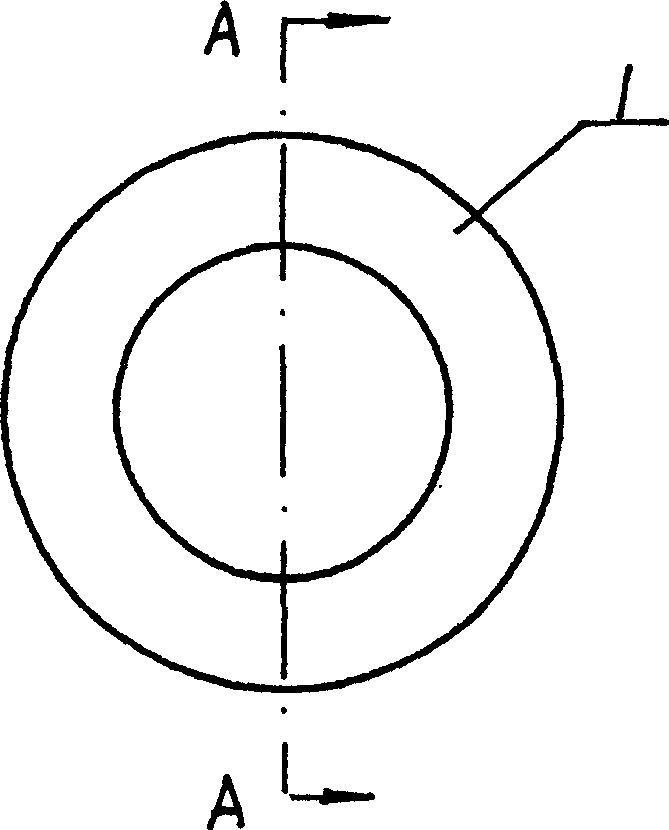

[0016] (1) A ring-shaped iron core 3 is wound into a circular iron core 3 by oriented silicon steel sheets along the paramagnetic direction, and then shaped by dipping in paint and drying.

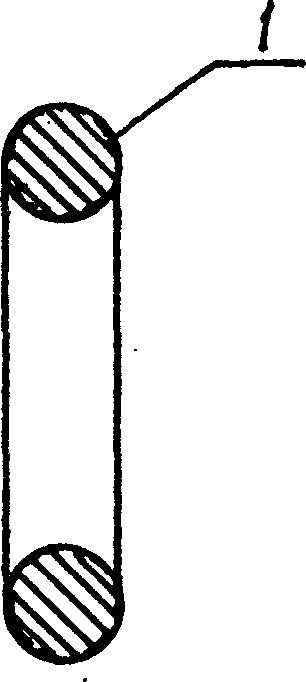

[0017] (2) Manufacture the magnetic gap: along the direction of the central axis of the ring, cut the ring-shaped iron core 3 into two half-rings 3-1, 3-2 by cutting method, and form two end faces at each cutting edge 3-1-1 and 3-2-1.

[0018] (3) Embedding magnetic gap gasket 4: use two glass fiber epoxy boards 4 with a preset thickness, respectively embedded in the magnetic gap formed by the two half-rings 3-1, 3-2, and clamp them with a clamp , forming a ring-shaped magnetic ballast core with two symmetrically arranged magnetic gaps.

[0019] (4) Stainless steel argon arc welding: The stainless...

Embodiment 2

[0024] Example 2: The iron core of the inductance ballast for the 400W metal halide lamp and the 250W high pressure sodium lamp uses two magnetic gaps, and each magnetic gap uses a stainless steel solder joint with a width of 5 mm and a depth of 2 mm.

Embodiment 3

[0025] Example 3: The iron core of an inductive ballast for a 36W fluorescent lamp uses two magnetic gaps, and each magnetic gap uses a stainless steel solder joint with a width of 3 mm and a depth of 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Radial depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com