Method for making macroporous silicon micro-channel with high aspect ratio

A technology with high aspect ratio and fabrication method is applied in the field of fabricating silicon microchannels and macroporous silicon microchannels with high aspect ratio, which can solve the problems of corrosion current destroying the structure, etc., and achieve easy-to-obtain aspect ratio and high aspect ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

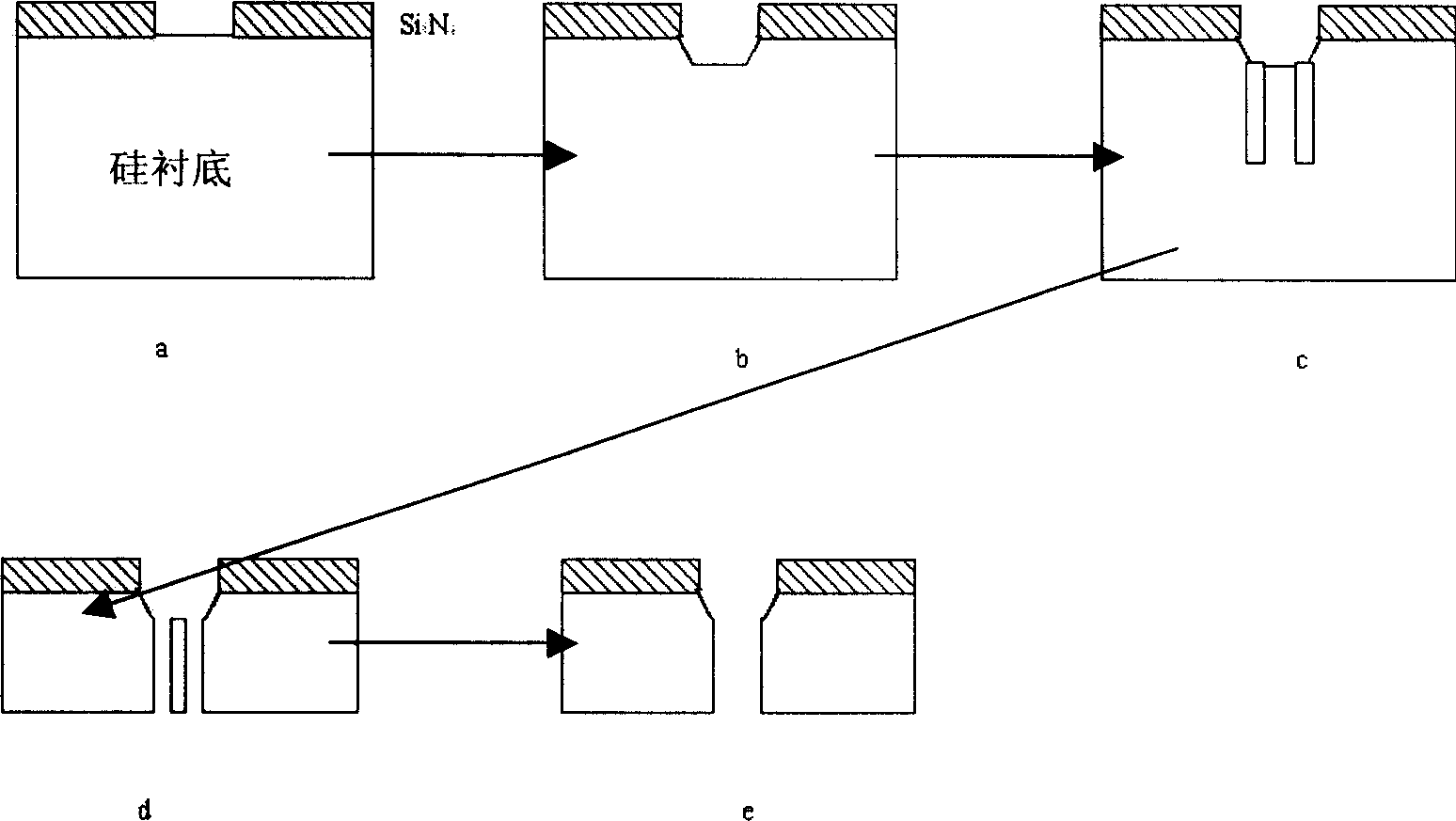

Embodiment 1

[0033] 1. Select n(100) silicon with a resistivity of 1 ohm / cm;

[0034] 2. Using LPCVD low stress silicon nitride (Si 3 N 4 ) as a mask;

[0035] 3. After defining the window (6μm×6μm) array by photolithography, take it out and clean it; then treat it with cetyltrimethylammonium bromide (TMAOH 25% 85°C) for 1 minute;

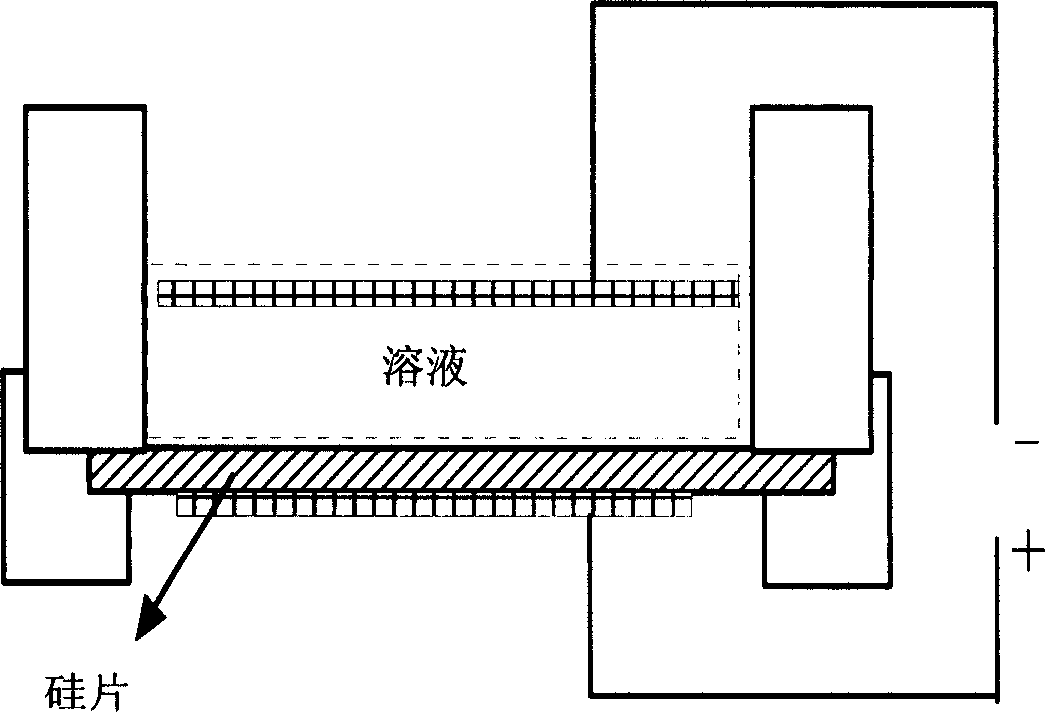

[0036] 4. Rinse and dry with deionized water, then use 40% HF and absolute ethanol C 2 h 5 The mixed solution obtained by mixing OH in a ratio of 1:7:8 is used as an anodic oxidation solution, and anodic oxidation is performed on the treated silicon wafer. The anodic oxidation is carried out at 20°C, and the average rate of corrosion is 50 μm / h; corrosion 8 Hour;

[0037] 5. Use dry oxidation to form a thin oxygen layer of 0.1 microns for front protection, and use HF solution to etch to remove the back oxide layer;

[0038] 6. Corrode with TMAOH (25wt%85°C) on the back side of the silicon wafer, and determine the end point of the back side thinning accord...

Embodiment 2

[0041] 1. Select p(100) silicon with a resistivity of 25 ohms / cm;

[0042] 2. Using LPCVD low stress silicon dioxide (SiO 2 ) as a mask;

[0043] 3. After defining the window (6μm×6μm) array by photolithography, take it out and clean it; then use KOH (20wt% 60°C) for 3 minutes;

[0044] 4. Rinse and dry with deionized water, then use hydrofluoric acid (HF), water and dimethylformamide (DMF) to mix the resulting solution in a ratio of 1:7:8 as an anodic oxidation solution. The silicon wafer is anodized, and the anodization is carried out at 20°C, and the corrosion is performed for 2 hours;

[0045] 5. Use dry oxidation to generate a thin oxygen layer of 0.1 microns for front protection; use hydrofluoric acid (HF) to etch to remove the back oxide layer;

[0046] 6. Corrode the back side of the silicon wafer with KOH (20wt% 60° C.), and determine the end point of the back side thinning according to the deep etched microchannel depth and the back side thinning rate;

[0047] 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com