Self-separation manufacturing method for silicon micro-channel structure

A manufacturing method and technology of silicon microchannels, which are applied in the field of micro-electromechanical systems, can solve problems such as easily damaged back surfaces, and achieve the effects of easy to obtain aspect ratio, high aspect ratio, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

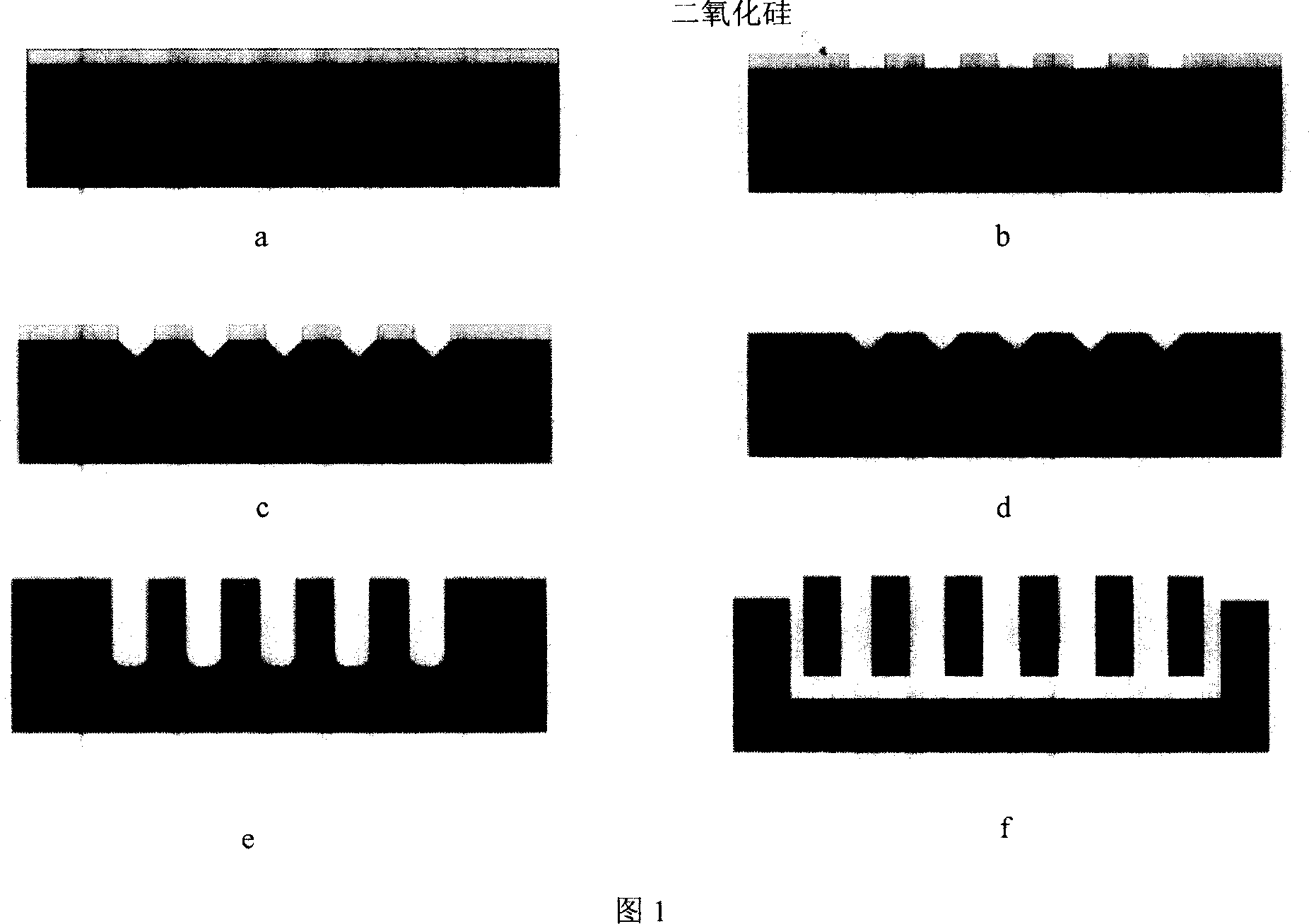

[0031] Embodiment 1, making a silicon microchannel plate for a low-light night vision image intensifier:

[0032] 1. Select a p-type silicon wafer with a 7-degree inclination in the (100) crystal direction, with a resistivity of 2-5 ohms / cm;

[0033] 2. Using thermal oxidation to form silicon dioxide (sio2) as a mask;

[0034] 3. After defining the window (3μm×3μm) array by photolithography, take it out and clean it; then treat it with tetramethylammonium hydroxide (TMAH 25wt%@80℃) for 1 minute;

[0035] 4. Use buffered hydrofluoric acid (BOE) to corrode for 2 minutes at 37°C;

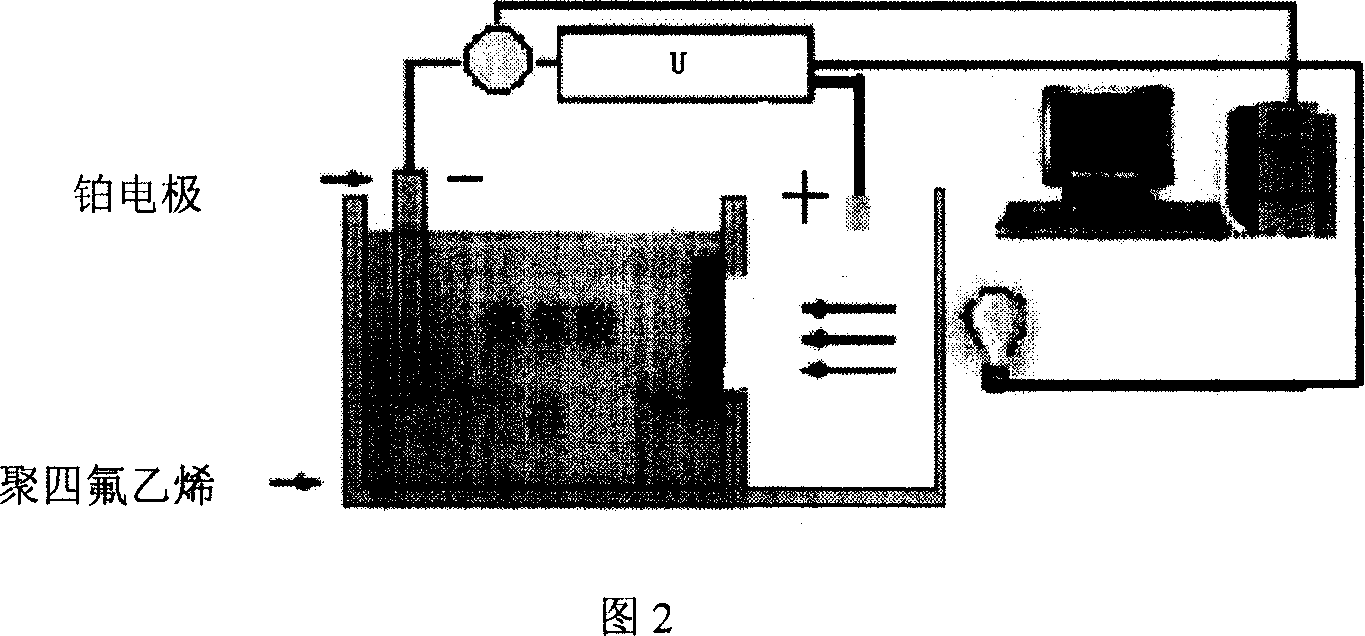

[0036] 5. Rinse and dry with deionized water, then use 40% HF and water to make a 4mol / l solution, and then mix it with tetramethylformamide (DMF) at a ratio of 1:1. After adding the active agent, add Hydrochloric acid (HCl), adjust the pH to 2, the resulting mixed solution is used as an anodic oxidation solution, anodic oxidation is carried out to the treated silicon wafer, anodic oxidation is carri...

Embodiment 2

[0041] Embodiment 2: Microchannel structure for making microbial filter:

[0042] 1. Select p-type silicon wafers in the (100) crystal orientation, with a resistivity of 2-5 ohms / cm;

[0043] 2. Using LPCVD low-stress silicon dioxide (SiO2) as a mask;

[0044] 3. After defining the window (3μm×3μm) array by photolithography, take it out and clean it; then use KOH (40wt%@80℃) for 3 minutes;

[0045] 4. Use buffered hydrofluoric acid (BOE) to corrode for 2 minutes at 37°C

[0046] 5. Rinse and dry with deionized water, then use 40% HF and water to make a 2mol / l solution, and then mix it with tetramethylformamide (DMF) at a ratio of 1:1. After adding the active agent, add Hydrochloric acid (HCl), adjust the pH to 4, and the resulting mixed solution is used as an anodic oxidation solution to anodize the treated silicon wafer. The anodic oxidation is carried out at 20°C, and the average rate of corrosion is 28 μm / h; corrosion 8 Hour;

[0047] 6. Separate the microchannel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com